Composition of white cement and preparation method thereof

A cement composition and composition technology, applied in the field of white cement composition and its preparation, can solve the problems of long purchase cycle, white cement storage and transportation restrictions, etc., to improve work efficiency, meet manufacturability, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

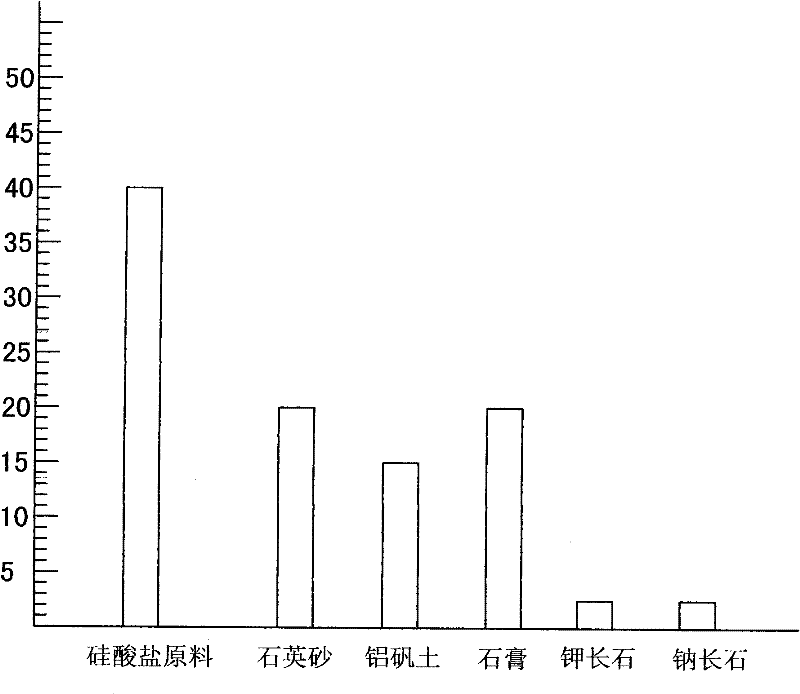

Embodiment 1

[0033] The composition ratio of the composition of white cement is:

[0034] 40% by weight of silicate raw material, 20% by weight of quartz sand, 15% by weight of bauxite, 20% by weight of gypsum, 2.5% by weight of potassium feldspar, and 2.5% by weight of albite feldspar.

[0035] After the white cement composition is mixed with water, it will start to solidify within 10-14 minutes, and will completely solidify within 30-50 minutes. Generally speaking, it will completely solidify within 30-40 minutes in summer, and in winter It takes 50 minutes to fully set. But compared with the performance of domestic white cement in the past, it has been improved a lot. The performance parameter comparison table of the following domestic white cement and white cement of the present invention:

[0036]

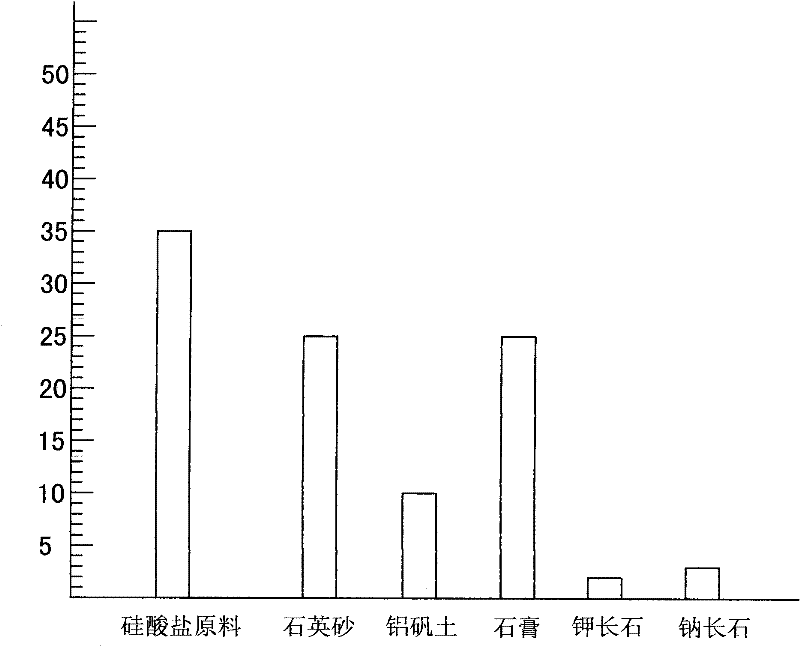

Embodiment 2

[0038] The composition ratio of the composition of white cement is:

[0039] 35% by weight of silicate raw material, 25% by weight of quartz sand, 10% by weight of bauxite, 25% by weight of gypsum, 2% by weight of potassium feldspar, and 3% by weight of albite feldspar.

[0040] After the white cement composition is mixed with water, it will start to solidify within 10-14 minutes, and will completely solidify within 30-50 minutes. Generally speaking, it will completely solidify within 30-40 minutes in summer, and in winter It takes 50 minutes to fully set. But compared with the performance of domestic white cement in the past, it has been improved a lot. The performance parameter comparison table of the following domestic white cement and white cement of the present invention:

[0041]

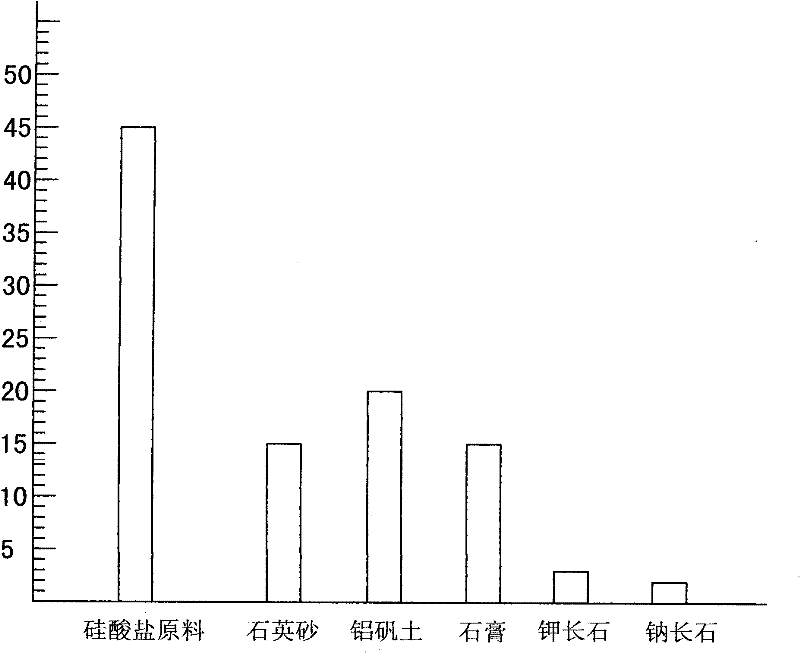

Embodiment 3

[0043] The composition ratio of the composition of white cement is:

[0044] 45% by weight of silicate raw material, 15% by weight of quartz sand, 20% by weight of bauxite, 15% by weight of gypsum, 3% by weight of potassium feldspar, and 2% by weight of albite feldspar.

[0045] After the white cement composition is mixed with water, it will start to solidify within 10-14 minutes, and will completely solidify within 30-50 minutes. Generally speaking, it will completely solidify within 30-40 minutes in summer, and in winter It takes 50 minutes to fully set. But compared with the performance of domestic white cement in the past, it has been improved a lot. The performance parameter comparison table of the following domestic white cement and white cement of the present invention:

[0046]

[0047] And the preparation method of the composition of white cement of the present invention is made up of the following steps:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com