Concrete composite shear wall

A combined shear wall and concrete technology, applied in the direction of walls, building components, earthquake resistance, etc., can solve the problems of increase, the overall control of the structure, the cost increase, etc., to achieve a clear force transmission mechanism, conducive to theoretical analysis, high bearing capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

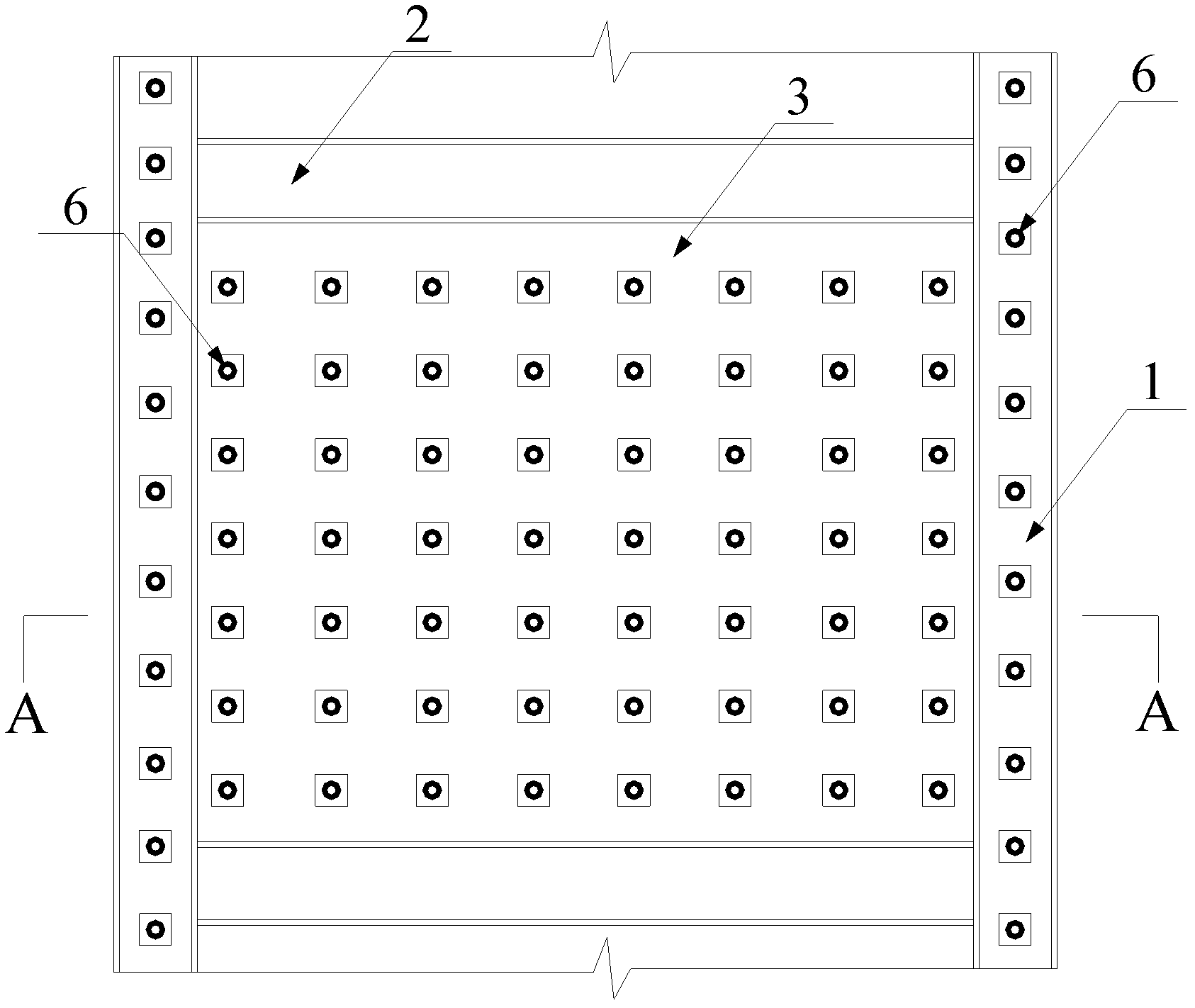

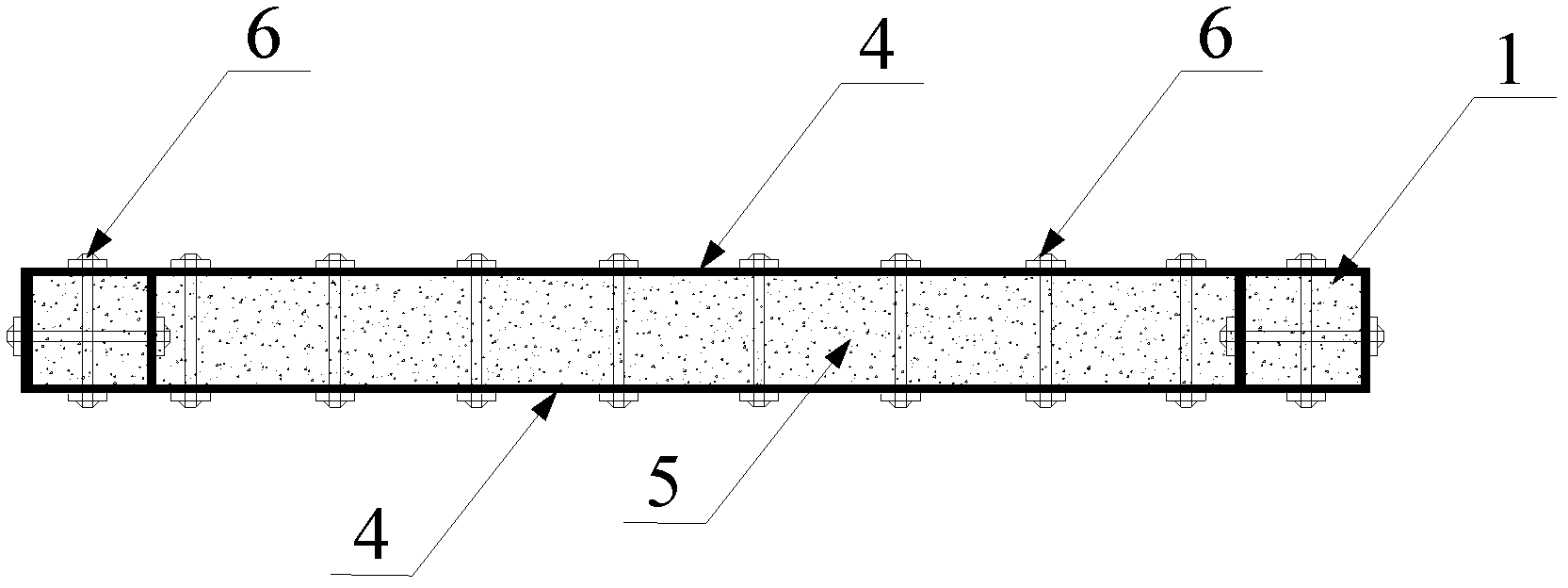

[0027] Such as figure 1 , figure 2 As shown, the concrete composite shear wall of the present invention includes a body of wall and a side column, and the body of wall is fixedly connected with the side column, and the body of wall 3 includes an array of tie rods 6 and a double-layer metal plate 4. The double-layer metal plate 4 constitute a sandwich, and a concrete wall panel 5 is arranged in the sandwich, and the constraint tie rod array 6 passes through the double-layer metal plate 4, and the concrete wall panel 5 is fastened to the sandwich of the double-layer metal plate 4 through the constraint tie rod array 6 Inside. Double-layer metal plate 4 adopts steel plate.

[0028] The distribution form of the constraining tie rod array 6 is a side-by-side array arrangement.

[0029] The side column is a steel tube concrete side column 1 composed of a steel pipe and a concrete column therein, and the steel tube of the steel tube concrete side column 1 is welded and fixed to t...

Embodiment 2

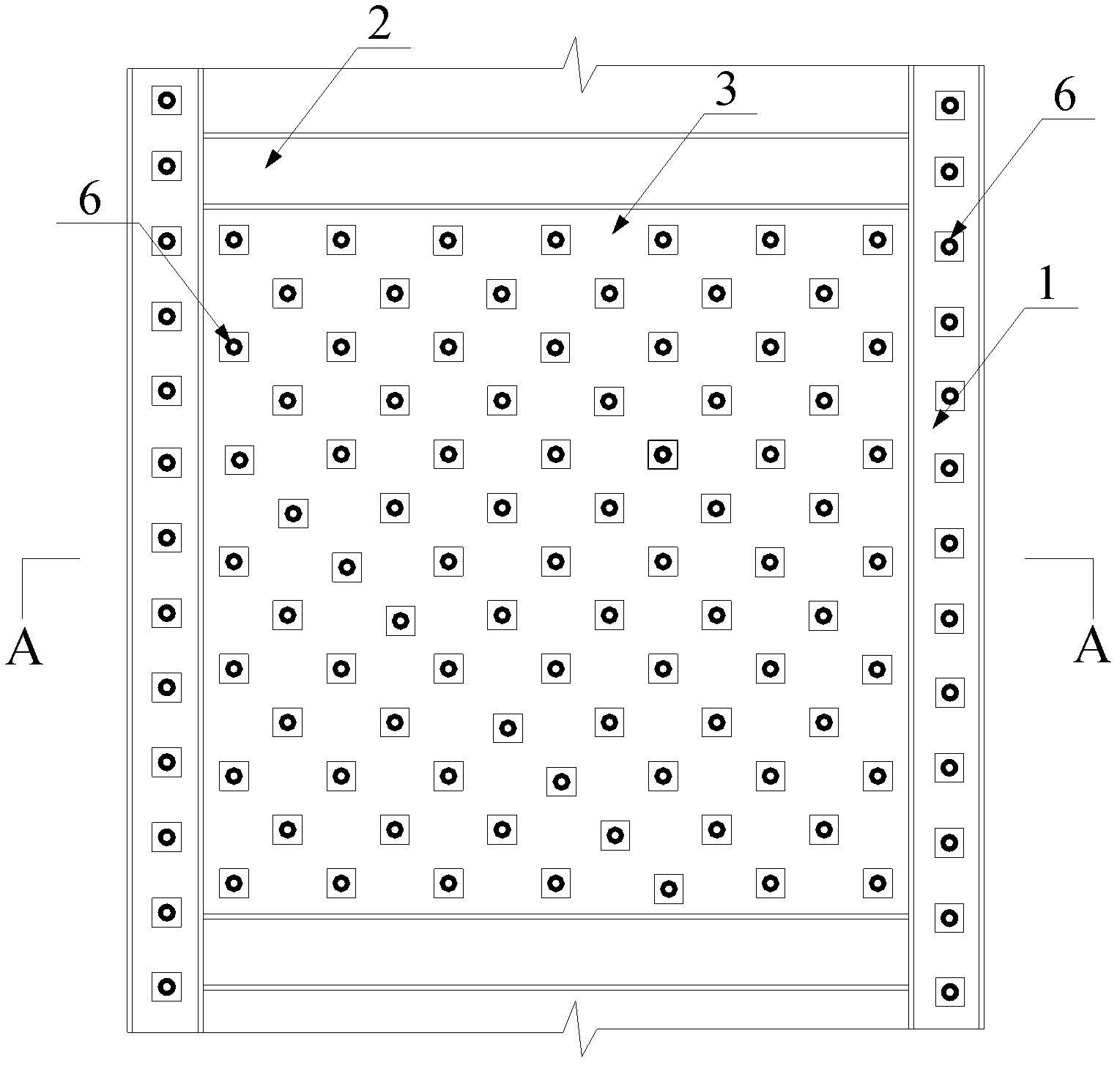

[0034] This embodiment is the same as Embodiment 1 except for the following features.

[0035] Such as image 3 , Figure 4 As shown, the distribution form of the constraining rod array 6 is a quincunx array arrangement.

Embodiment 3

[0037] This embodiment is the same as Embodiment 1 except for the following features.

[0038] Such as Figure 5 , Figure 6 as shown,

[0039] The cross-sectional shape of the steel pipe concrete side column 1 is circular.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com