Heat radiator

A heat sink and heating element technology, applied in the direction of electric solid devices, semiconductor devices, semiconductor/solid device components, etc., can solve the problem of insufficient heat removal effectively

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

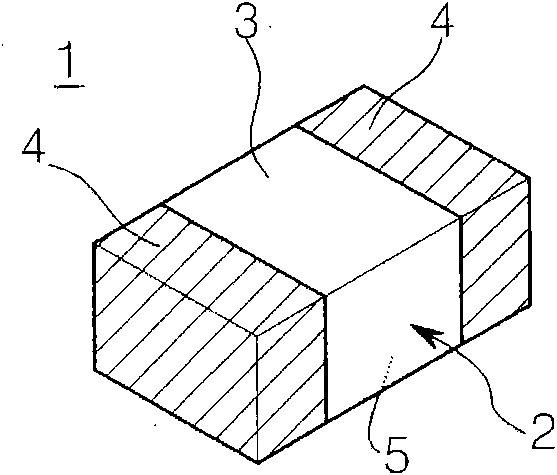

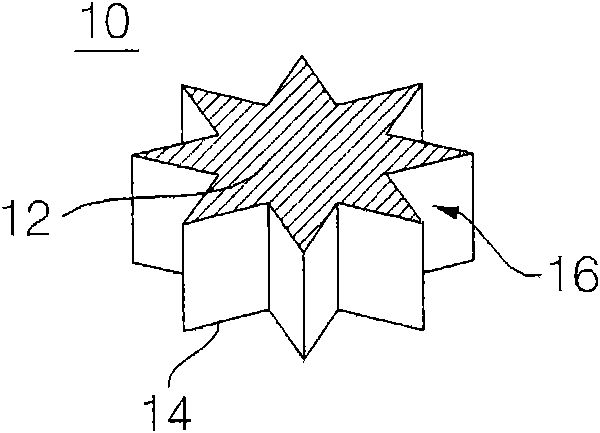

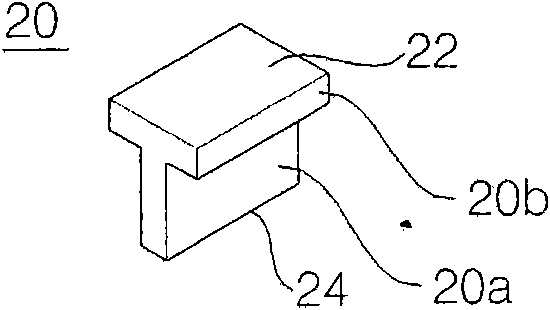

[0053] Figure 1A , Figure 1B with Figure 1C are perspective views respectively showing different heat sinks 1, 10 and 20 according to embodiments of the present invention.

[0054] Such as Figure 1A As shown in , the heat sink 1 has a three-dimensional (3D) rectangular shape. The heat sink 1 includes: a horizontal back 5 and a front 3; a main body 2 made of thermally conductive ceramics or carbonaceous materials. A metal layer 4 surrounds both sides of the body 2 in order to be able to apply reflow soldering to the solder paste. However, the heat sink 1 is not limited to the above structure, and the metal layer 4 may be formed only on the rear surface of the main body 2 . The heat sink 1 can be reflow soldered to solder paste through the metal layer 4 formed at least on the back side.

[0055] The heat sink 1 according to the present emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com