Exhaust gas after treatment system with temperature control

A technology of exhaust aftertreatment and emission control system, which is applied in exhaust treatment, exhaust device, air quality improvement, etc., and can solve problems such as SCR failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

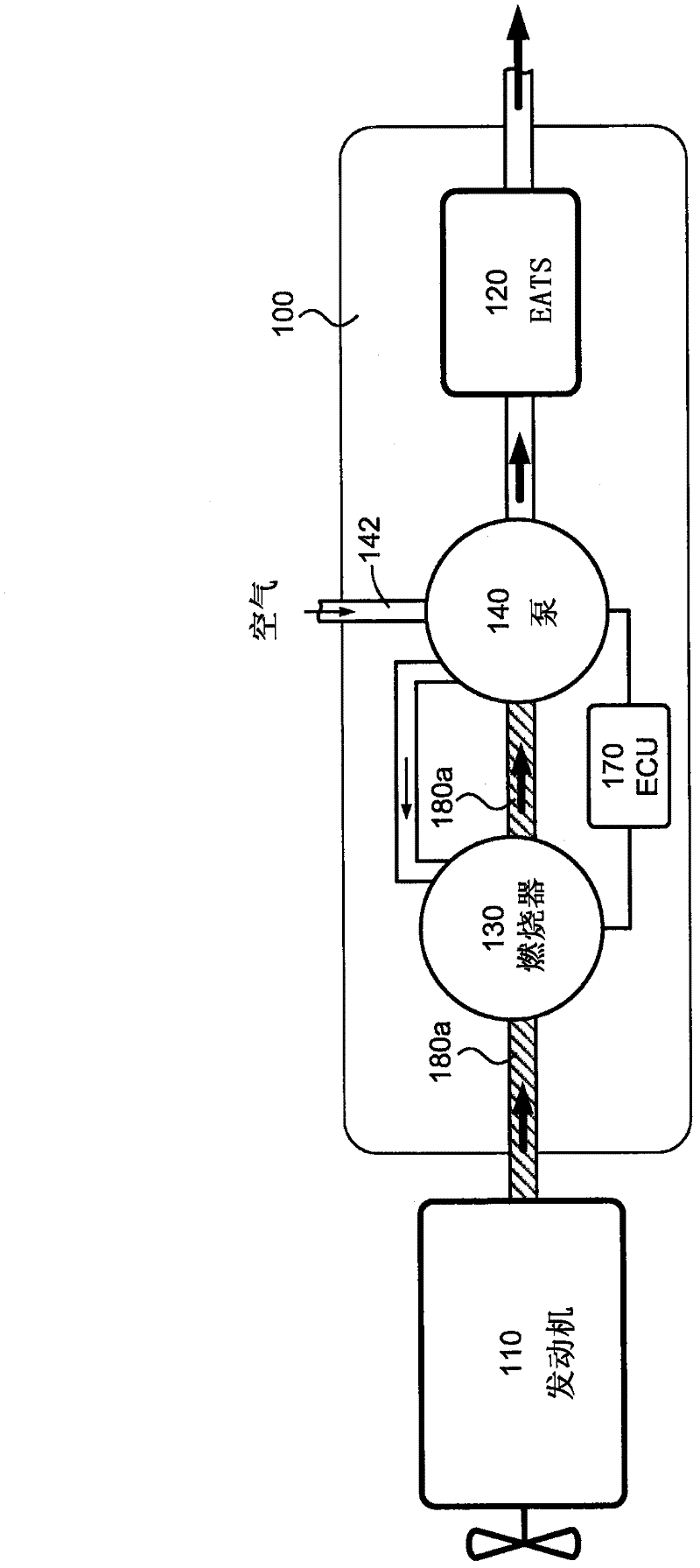

[0024] figure 1 is a general schematic diagram of an emission control system 100 configured to receive exhaust gas from a combustion engine 110 according to one embodiment of the present aspect. Emission control system 100 includes EATS 120 configured to operatively clean exhaust gas received from engine 110 . The emission control system 100 is provided with: a burner unit 130 configured to operably heat the received exhaust gas to a predetermined temperature prior to providing the exhaust gas to the EATS 120; and a pump unit 140 , the pump unit 140 is configured to operatively supply the burner unit 130 with air to be used by the burner unit 130 during heating in the burner unit 130 . Typically, the pump unit 140 is configured to be operably driven by the exhaust gas. The burner unit 130 is arranged upstream of the pump unit 140 so that exhaust gas from the burner unit 130 is operatively provided to the pump unit 140 to drive the pump unit 140 .

[0025] Using a separate b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com