Dental implant operation guide plate and manufacturing method thereof

A manufacturing method and surgical technology, applied in the fields of dental implants, dental repairs, dentistry, etc., can solve the problems of high manufacturing costs, complexity, and increased manufacturing costs, and achieve the goals of improving accuracy, simplifying the manufacturing process, and reducing time and money. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the above and other objectives, features and advantages of the present invention more obvious and understandable, the following is a detailed description of the preferred embodiments of the present invention in conjunction with the accompanying drawings:

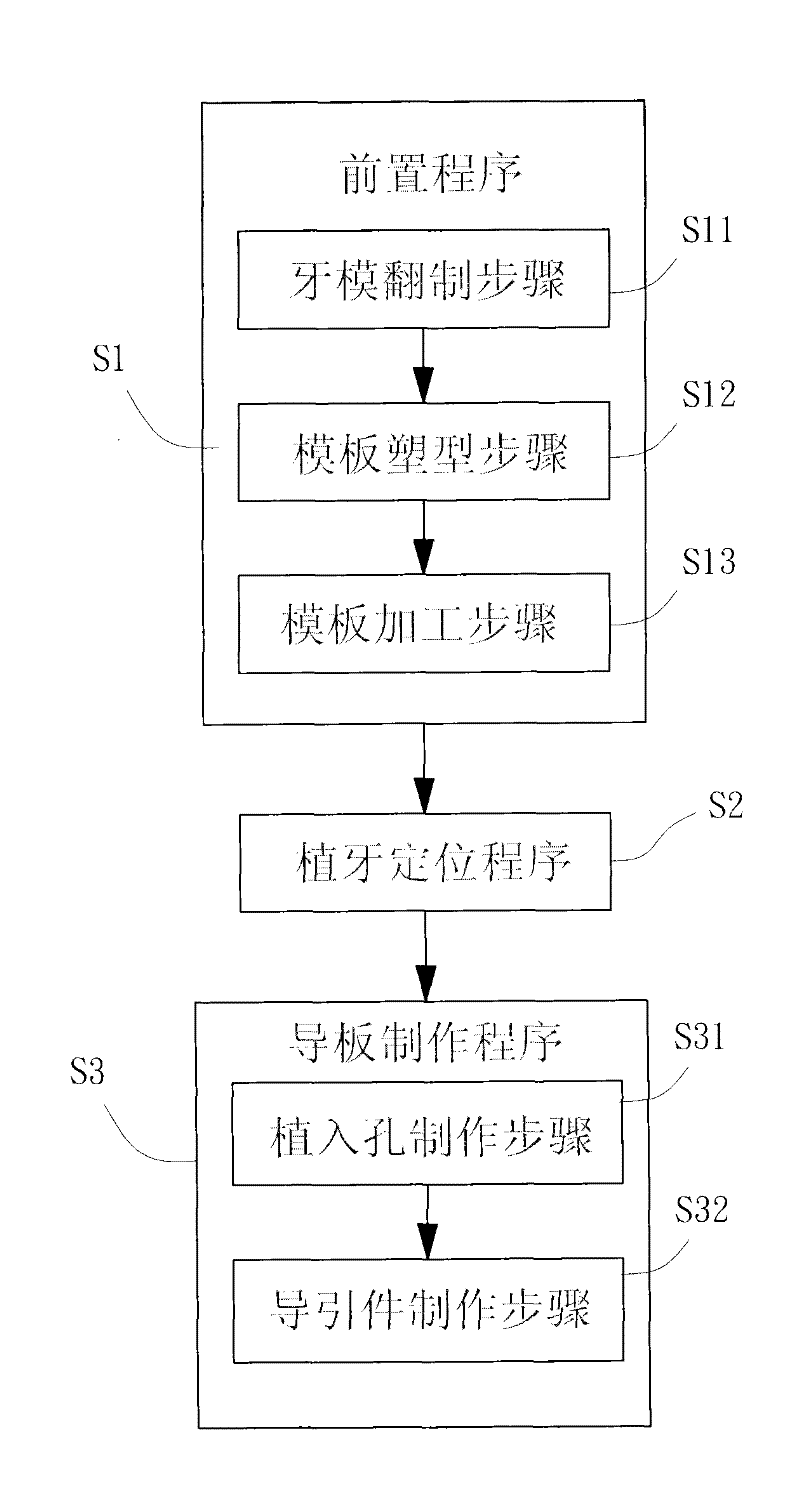

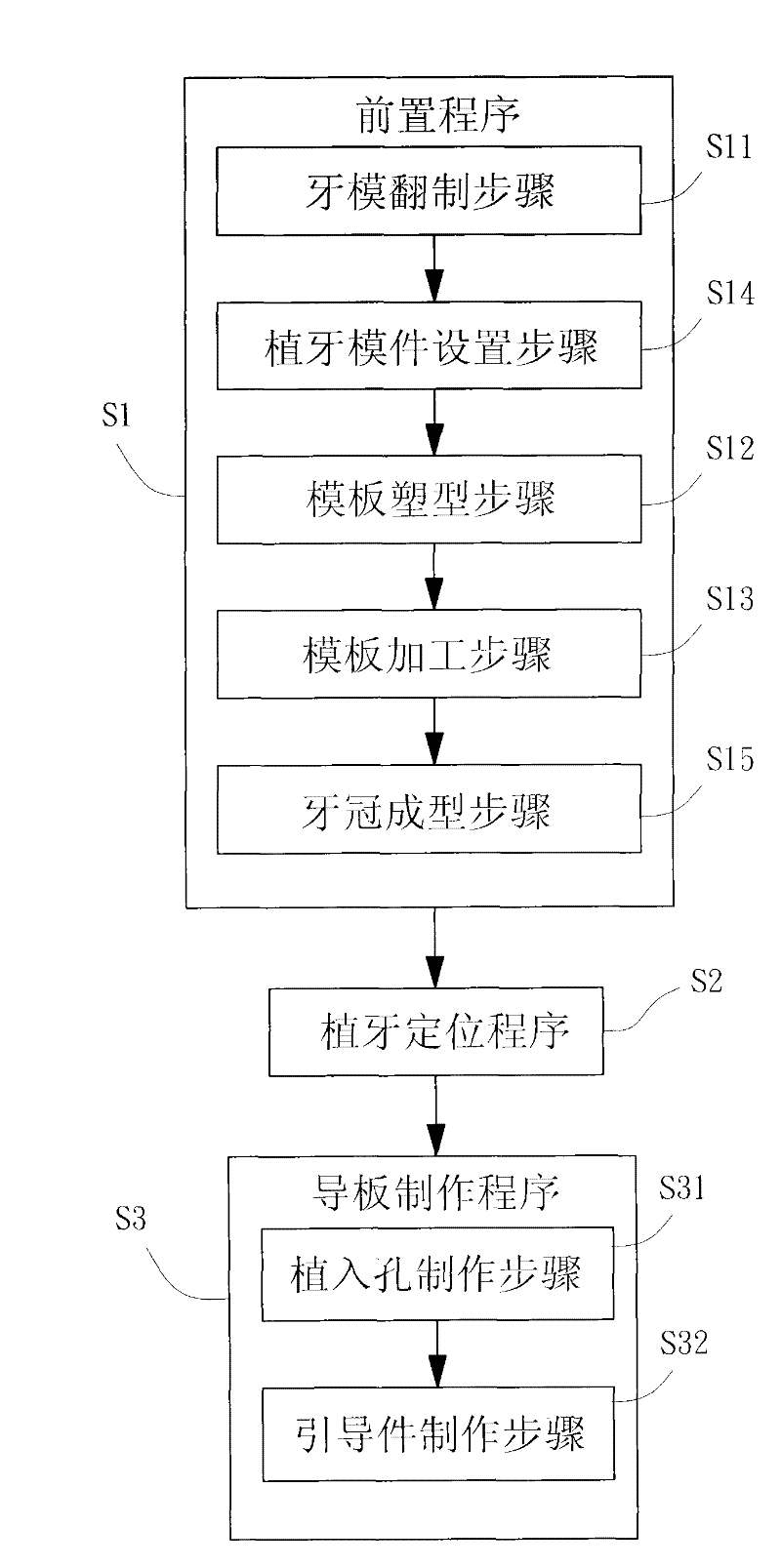

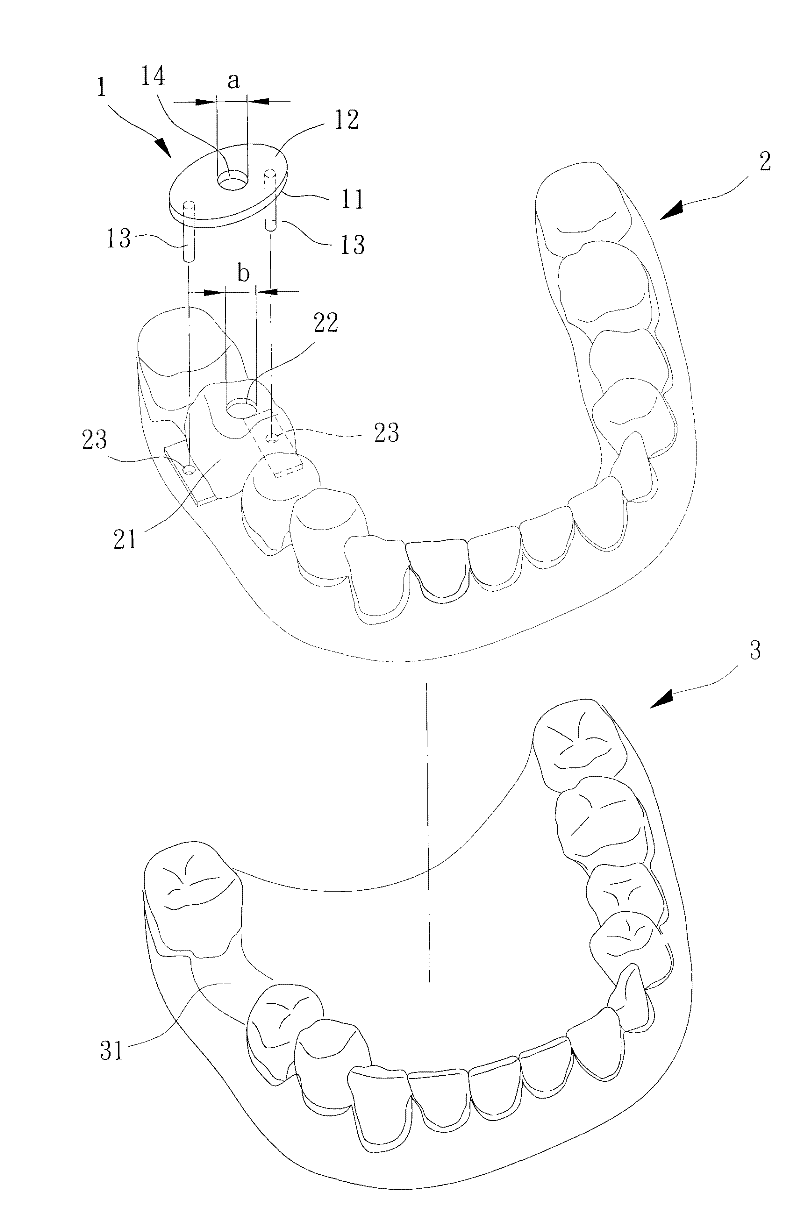

[0042] Such as figure 1 Shown is a flow chart of the method for manufacturing a guide plate for dental implant surgery of the present invention, including a pre-procedure S1, a dental implant positioning procedure S2, and a guide plate making procedure S3.

[0043] The pre-procedure S1 further includes a dental mold reproducing step S11, a template shaping step S12, and a template processing step S13; wherein the dental mold reproducing step S11 is to reproduce an entity according to the patient’s oral condition Dental model to obtain information on the affected part of the patient’s mouth.

[0044] The template shaping step S12 is to use a thermoplastic material to accurately present the surface features of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com