Vacuum melting die-casting equipment

A vacuum smelting and equipment technology, which is applied in the field of metal forming equipment, can solve the problems of electric plate glow discharge, complex equipment structure, and high transformation cost, and achieve the effects of improving reliability, simplifying equipment, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

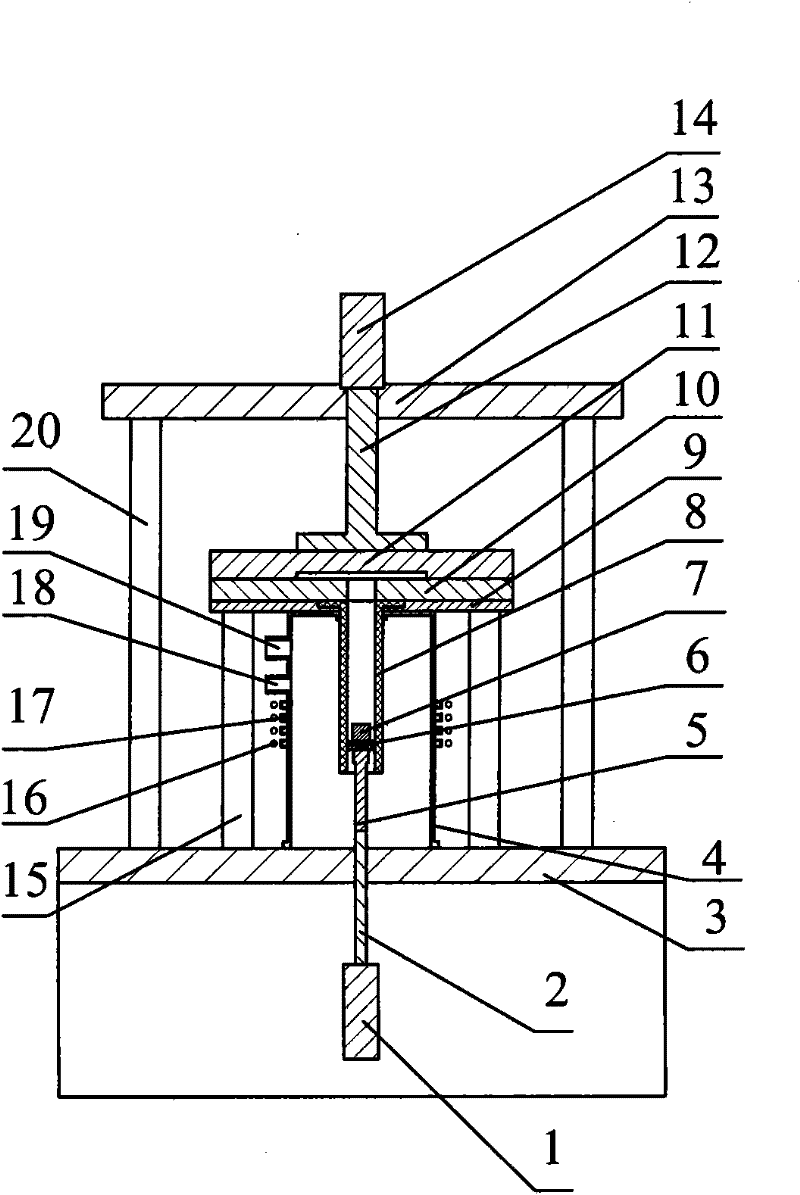

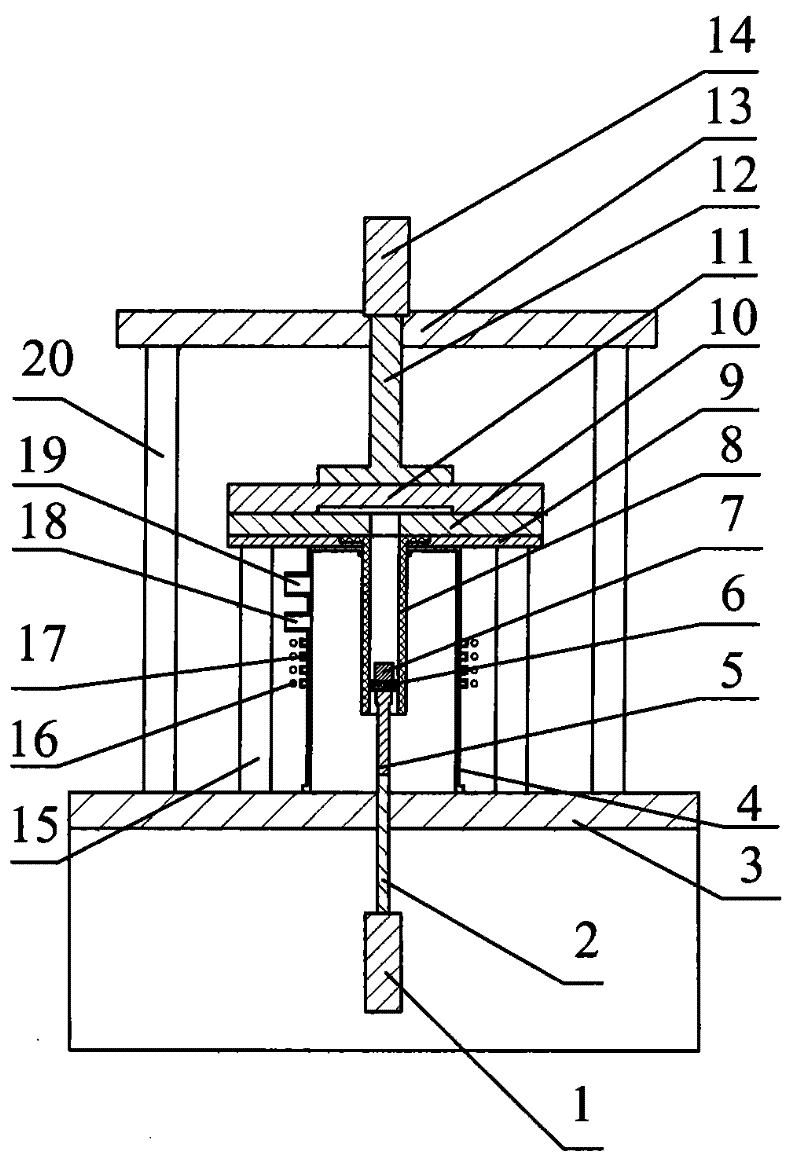

[0008] In order to make the technical problems, technical solutions and beneficial effects solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0009] Preferably, the product forming mold is located above the smelting device, and the injection device pushes the molten metal blank in the barrel to the product forming mold from bottom to top. Bottom-up injection prevents the molten liquid metal billet from rolling up due to flow during the lateral injection process, resulting in the formation of many pores in the product, which affects the quality of the formed metal product. The traditional smelting crucible will have residues and scales after a smelting and pouring process, which is troublesome to clean up, and impurities are easily introduced in the subsequent metal smelting process, which affects product performance. In the present invention, the molten metal b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com