Method for synthesizing high-content allyl isothiocyanate

A technology of allyl isothiocyanate and synthesis method, applied in the direction of organic chemistry, etc., can solve the problems of low extract content and long cultivation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

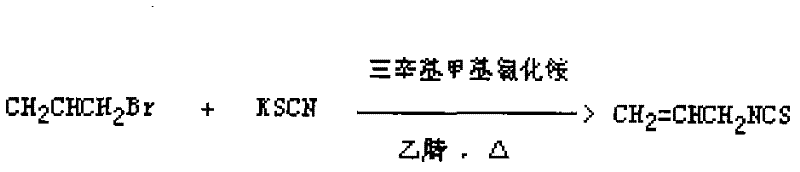

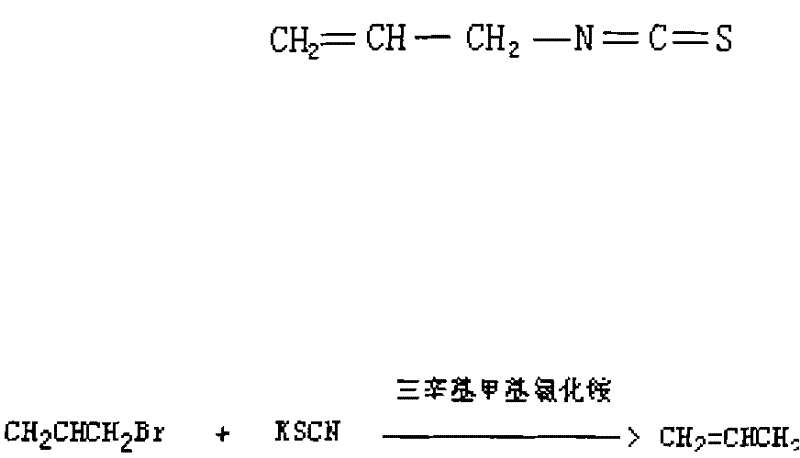

Method used

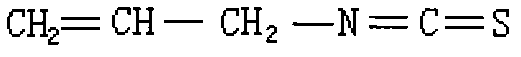

Image

Examples

Embodiment 1

[0008] Take 12.1 g of allyl bromide, add it to 200 ml of acetonitrile, then add 9.7 g of potassium hydrosulfide, stir in a water bath, control the temperature at 10-20°C, add 0.1 g of trioctylmethyl ammonium chloride after 5 minutes, and raise the temperature to 30°C, heat-preserve at 30-40°C for reaction, filter with suction after 1 hour, and distill the filtrate under atmospheric pressure to obtain allyl isothiocyanate with a yield of 98.1%.

Embodiment 2

[0010] Take 12.1 grams of allyl bromide, add it to 200 ml of acetonitrile, then add 9.7 grams of potassium hydrosulfide, stir in a water bath, control the temperature at 20 ° C, add 0.05 g of trioctylmethyl ammonium chloride after 5 minutes, and heat up to 50 ℃, heat preservation reaction at 50-55 ℃, suction filtration after 1 hour, and atmospheric distillation of the filtrate to obtain allyl isothiocyanate with a yield of 98.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com