Power-off brake device

A technology of braking device and braking effect, applied in the direction of braking actuators, gear transmission mechanisms, brake types, etc., can solve problems such as difficult to use the rotary table, difficult to grasp the brake clearance, and the deflection of the brake table

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

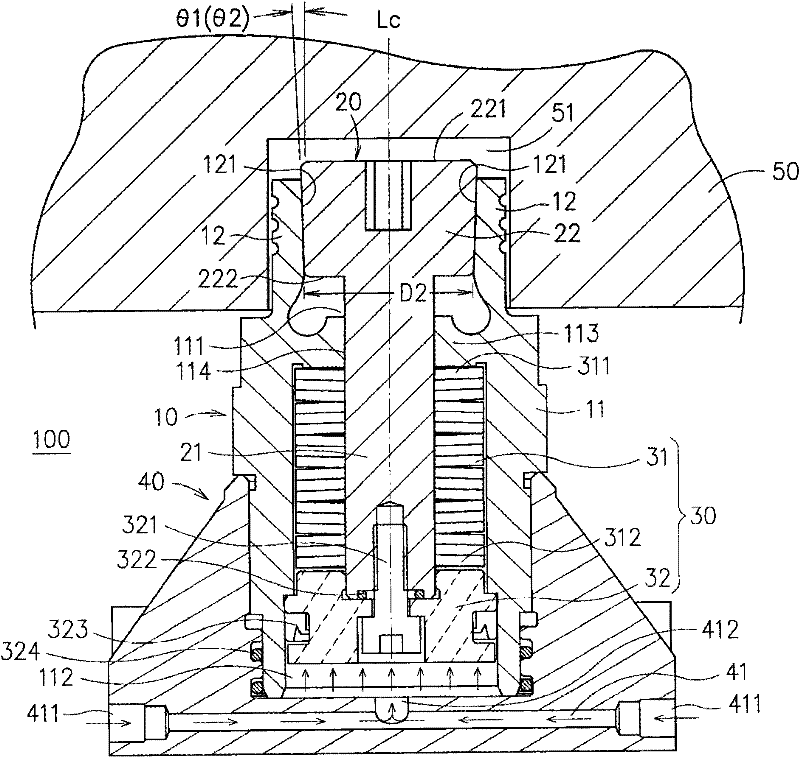

[0057] The technical means and effects used by the present invention to achieve the purpose will be described below with reference to the accompanying drawings, and the embodiments listed in the following drawings are only for auxiliary explanation, so as to facilitate the understanding of the examiners, but the technical means of this case are not Not limited to the figures listed.

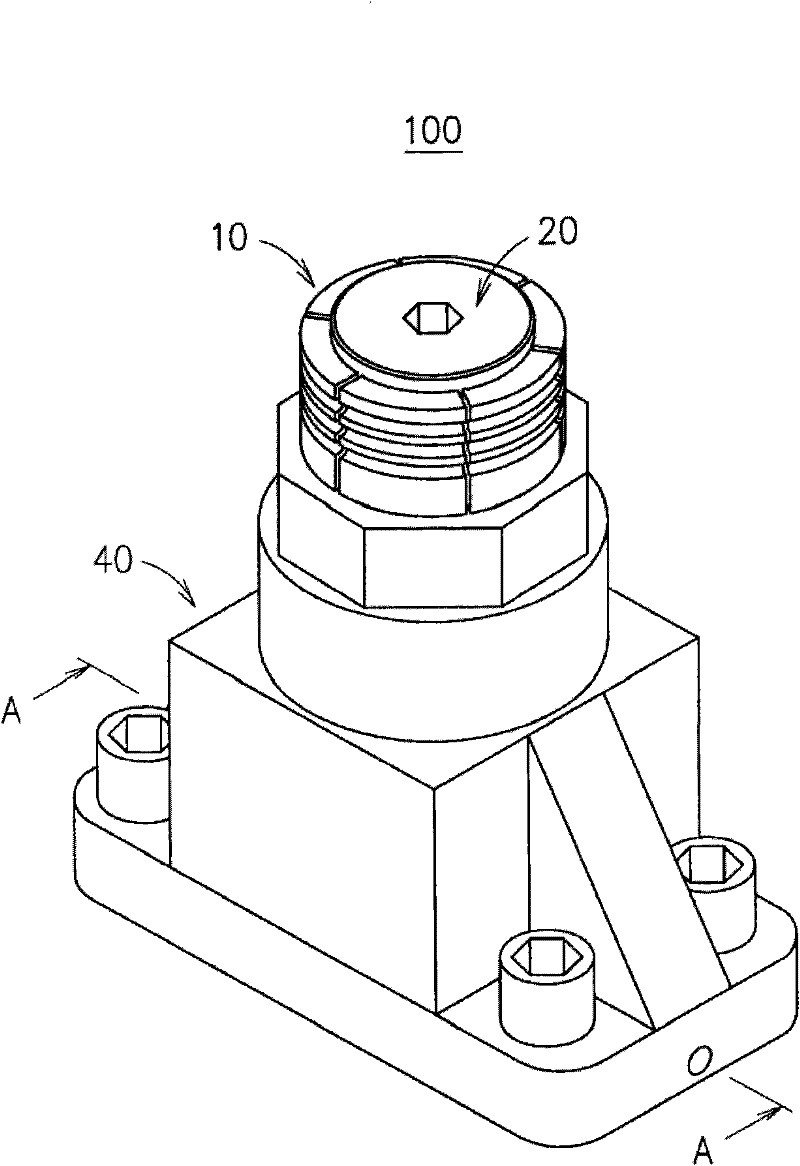

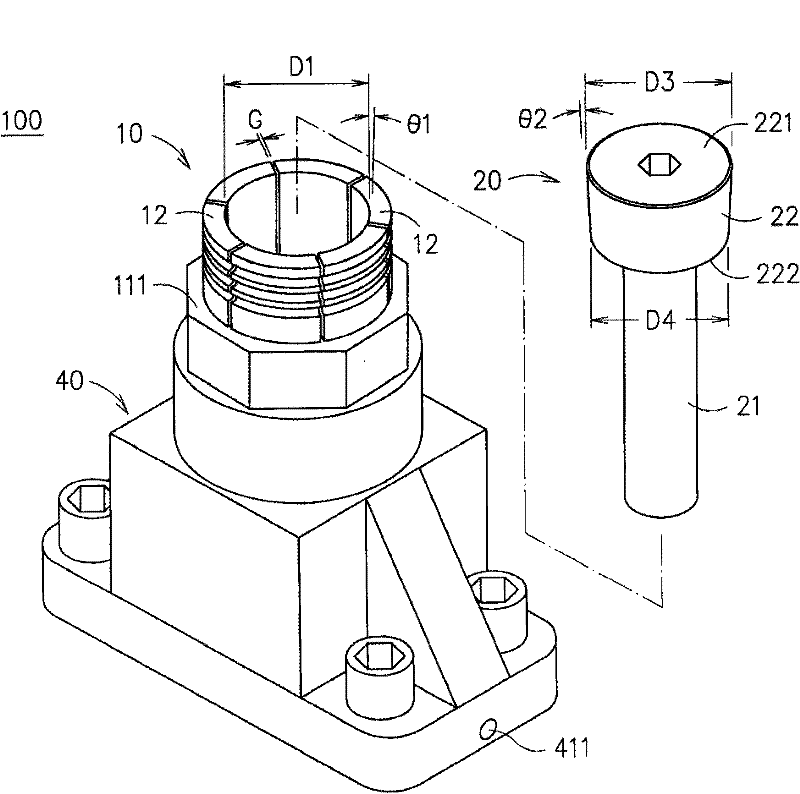

[0058] see Figure 1 to Figure 3 As shown, the power-off brake device 100 provided by the present invention includes an elastic claw element 10, a spindle 20 and a driving device 30, and the elastic claw element 10, the spindle 20 and the driving device 30 are arranged on a base 40 .

[0059]The elastic claw element 10 has a tubular main body 11, the tubular main body 11 has an axis Lc, and the tubular main body 11 has a first end 111 and a second end 112 opposite and communicating with each other along the axis Lc. The first end 111 of the tubular body 11 is provided with a partition 113, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com