High lift system for aircraft, aircraft system and propeller aircraft with high lift system

A technology of aircraft and propeller, which is applied in the field of propeller aircraft, can solve the problems of increased weight, achieve the effect of reducing operating costs and reducing development risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

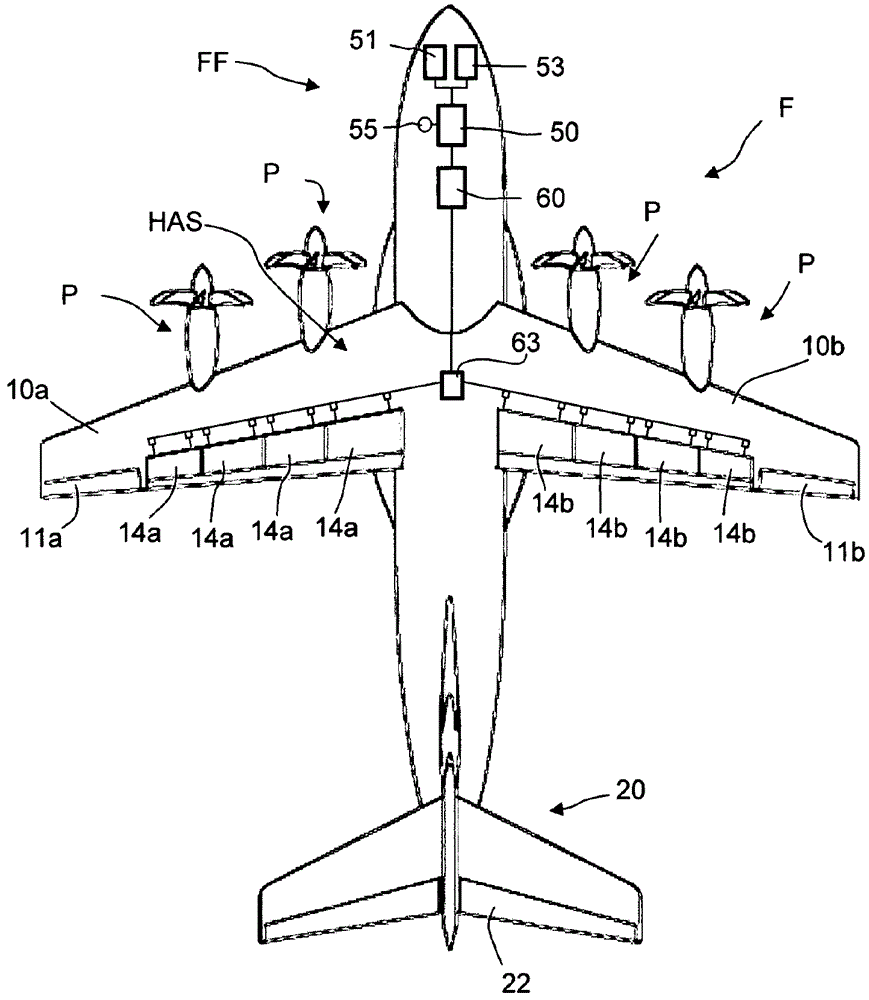

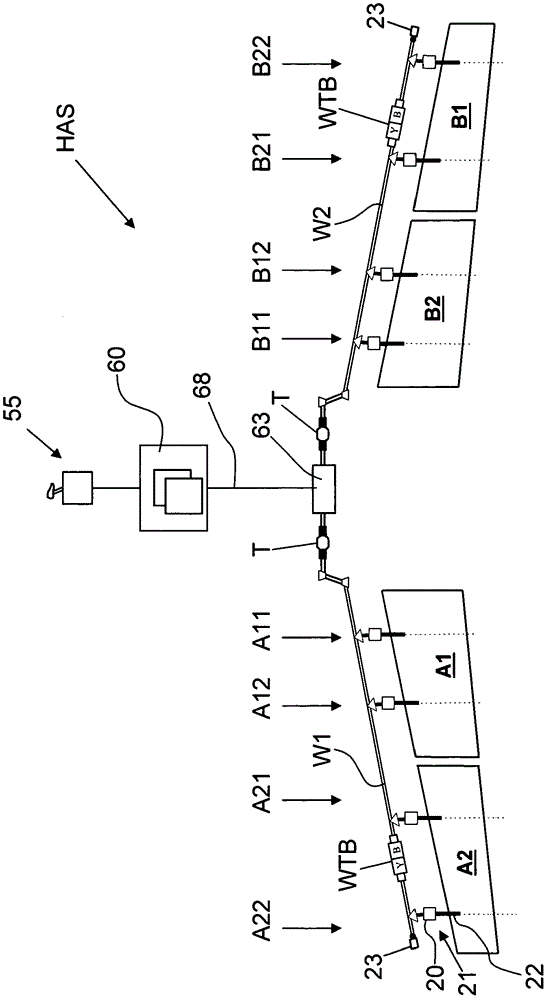

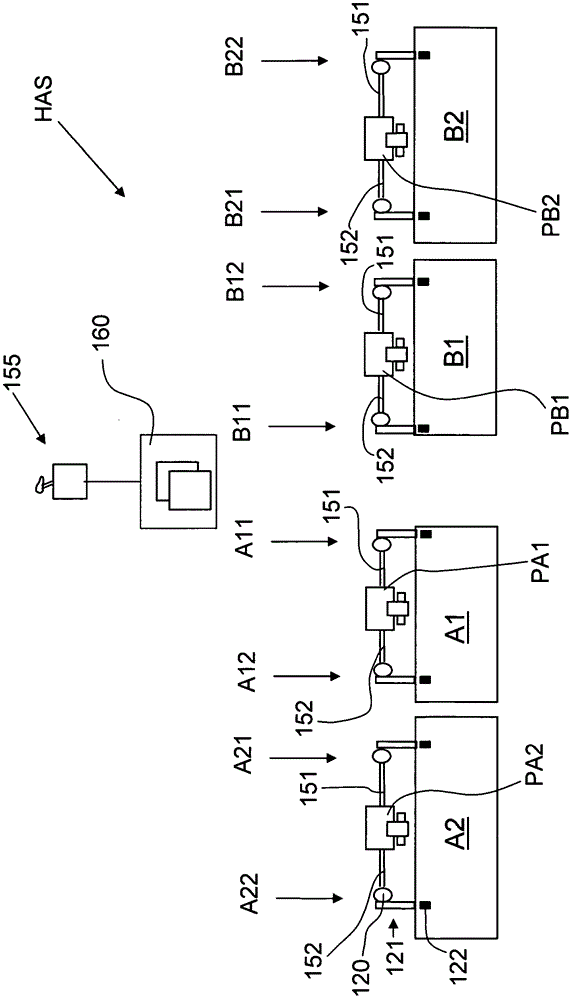

[0046] figure 1 An example of an embodiment of an aircraft F featuring closed-loop control with two wings 10a, 10b is shown. The wings 10a, 10b each have at least one aileron 11a or 11b, respectively, and at least one trailing edge flap 14a, 14b. The wings 10a, 10b can each optionally have a plurality of spoilers and / or slats. Furthermore, the aircraft F has a vertical empennage unit 20 with at least one rudder and one elevator 22 . The vertical tail unit 20 can be designed, for example, as a T-tail unit or as a cross-tail unit. The aircraft F may in particular be a propeller aircraft with propellers driven by the engines P. In the case of the latter, in particular it can be arranged that in a propeller aircraft, the propeller driven by the engine P is mounted on the wings 10a, 10b, such as figure 1 shown in . In addition, the propeller aircraft F may be a high-wing aircraft.

[0047] The aircraft F or the flight management system FF has a flight control device 50 and an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com