Gas leakage reduction system

A gas and air leakage technology, applied in the direction of flue gas combustion, indirect carbon dioxide emission reduction, steam boiler accessories, etc., can solve the problems of increasing the total pressure of flue gas and the difficulty of condensation in the gas treatment system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

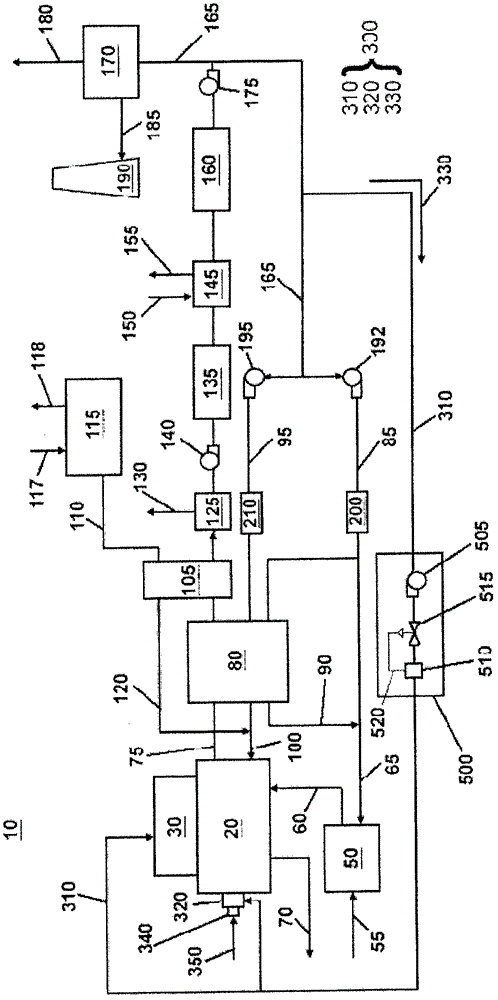

[0019] Disclosed herein is a system for a power plant, and more particularly, a system for significantly reducing and / or effectively minimizing air leakage (eg, air leaks) into a boiler of an oxy-fired power plant Gas leak reduction system. refer to figure 1 , the power plant 10 includes a furnace 20 . In the exemplary embodiment, furnace 20 is an oxy-fired boiler, but is not limited thereto. For example, furnace 20 may be a conventional boiler (not shown) or a CO 2 A capture preparation boiler (not shown), although the alternative exemplary embodiment is not limited thereto. For illustration purposes only, the following will figure 1 The oxy-fired boiler 20 shown in Power Plant 10 is discussed.

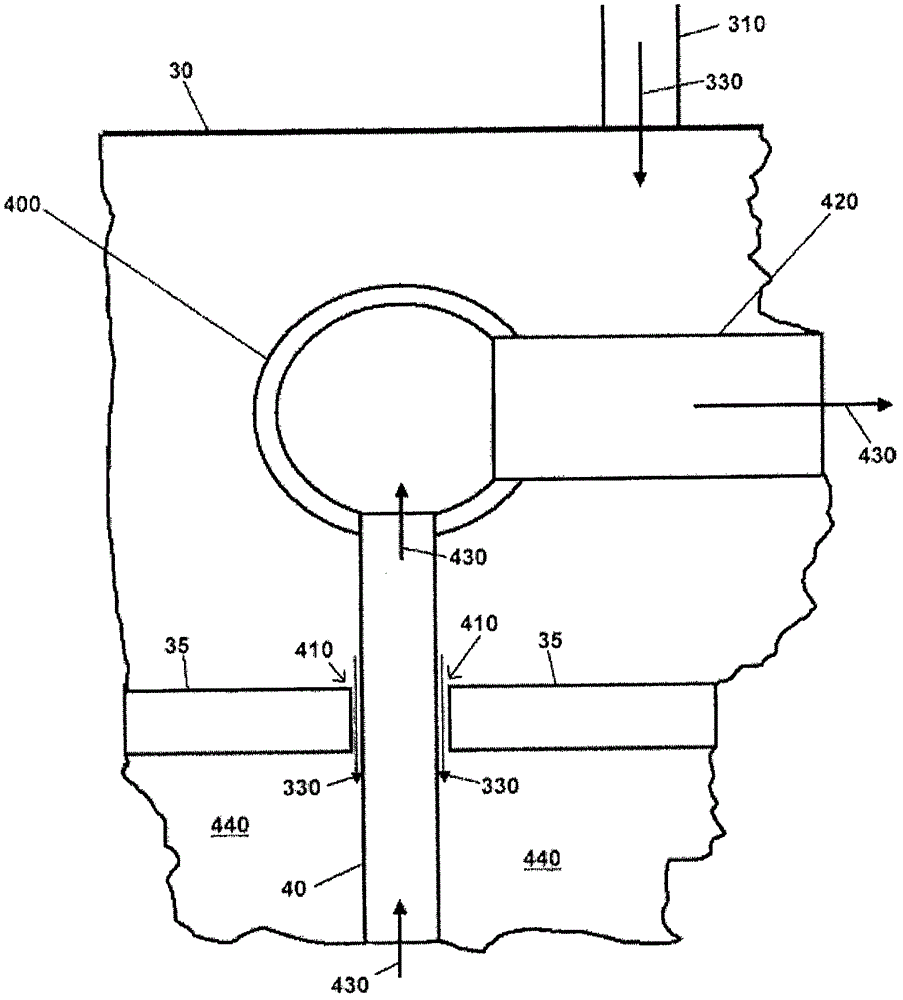

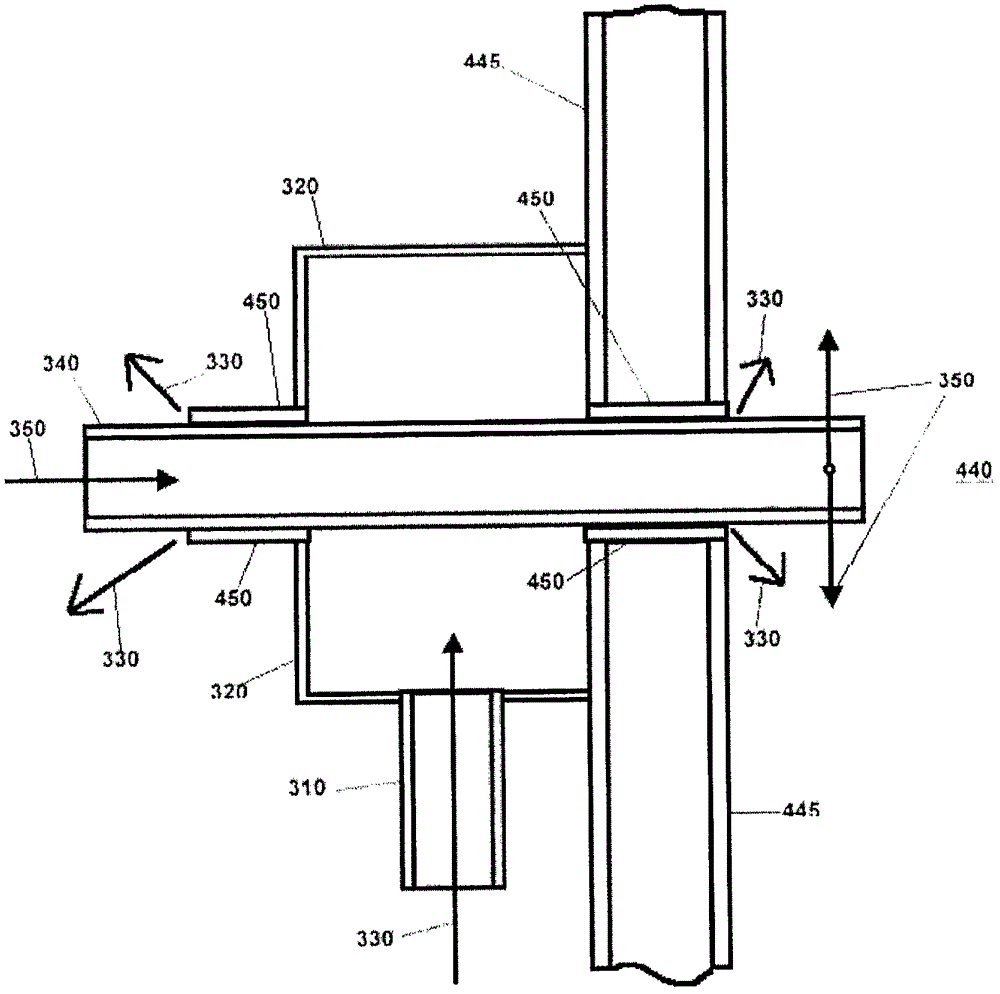

[0020] The power plant 10 according to the exemplary embodiment also includes a boiler roof 30 located above the oxy-fired boiler 20, such as figure 1 shown in . More specifically, the boiler roof 30 is positioned adjacent the boiler top tube panel 35 to receive the heat excha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com