Instrument connection type unit pack combined cell cartridge

A technology of battery cells and cell groups, applied in the direction of secondary batteries, battery pack components, circuits, etc., can solve the problems of inability to increase the current capacity of battery cells, ineffective use of cable space, and inability to exceed current capacity, etc. , to achieve the effect of solving low stability, eliminating current/voltage imbalance, and minimizing contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

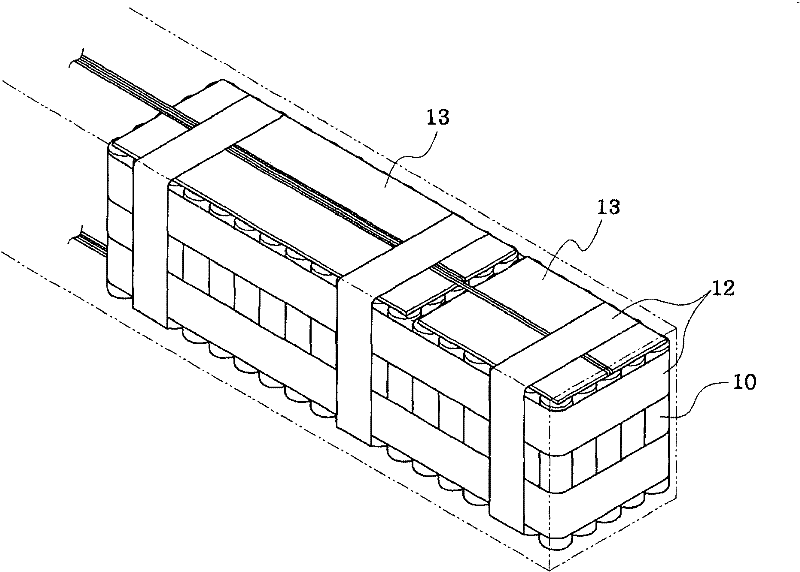

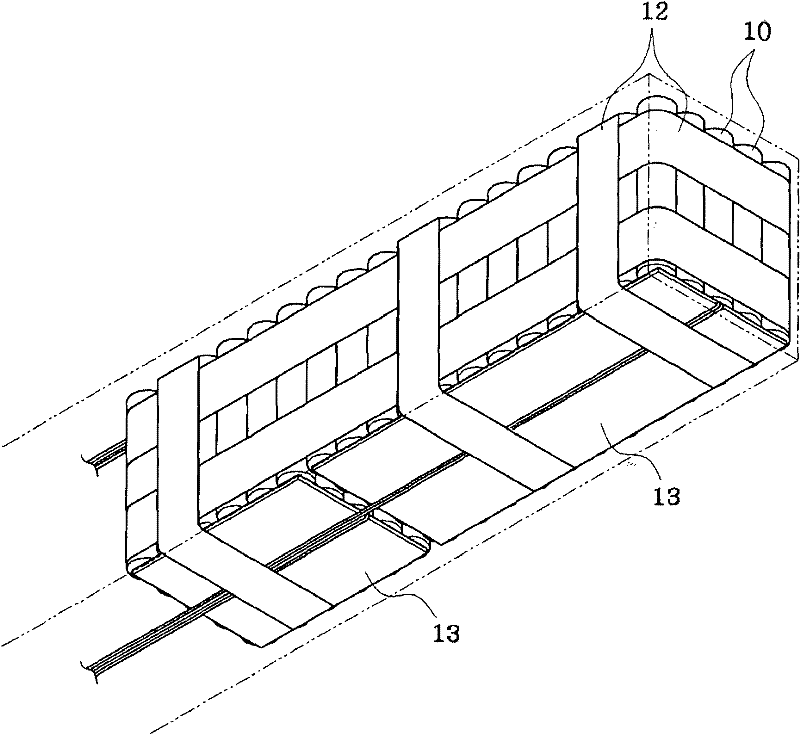

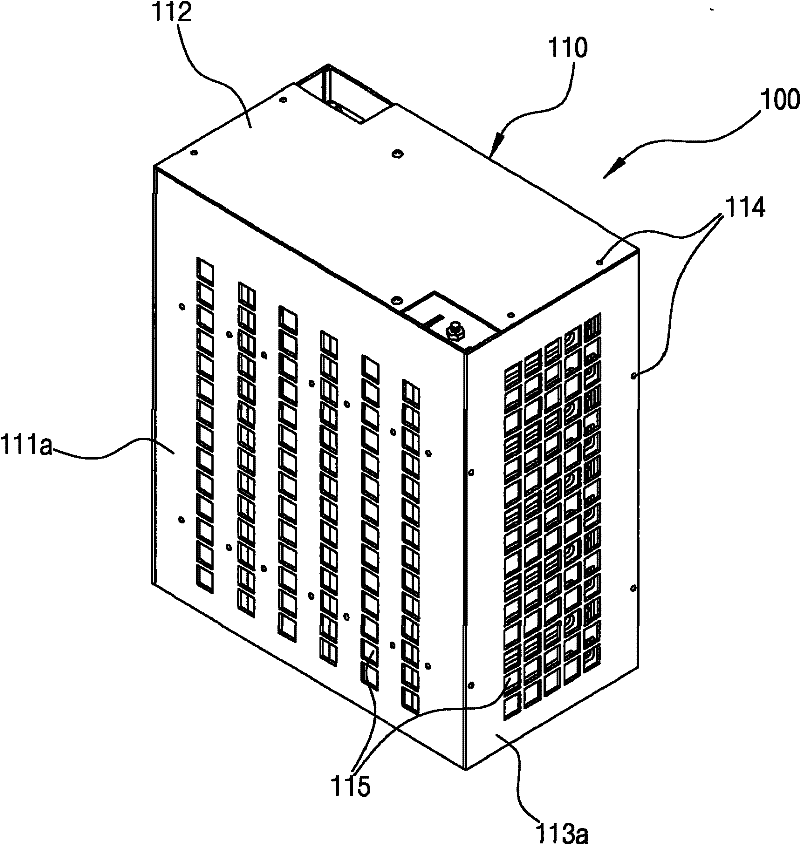

[0043] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0044] The unit pack combination type battery cell case of the present invention is characterized in that after connecting a plurality of battery cells (cells) using a tool (bus line) to form a unit pack (unit pack), the plurality of unit packs are assembled using a tool (intermediate conductor). Boards) are connected to form, and there are no cables and connectors in the unit group combination type battery unit case, and the entire unit group is formed and connected only by tools.

[0045] The cell pack combination type battery cell case of the present invention connects the battery cell and the cell pack using tools that are easy to connect and detach, so assembly performance and productivity are greatly improved, and (in the power storage device of the present invention) adjustment and change are possible. The current and voltage capa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com