Method for preparing and purifying struvite from residual sludge

A technology of excess sludge and struvite, applied in the field of resources and environment, to achieve rapid results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

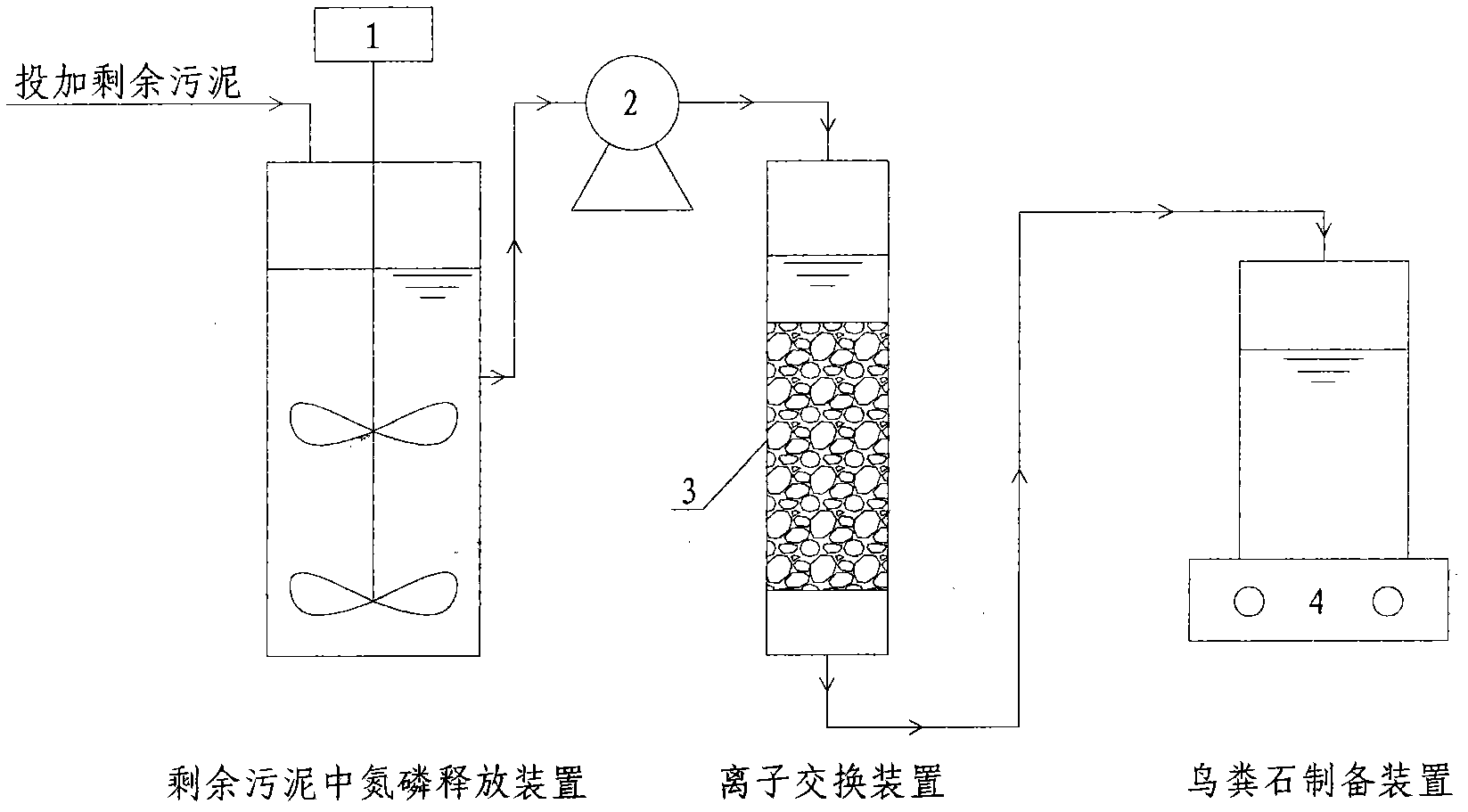

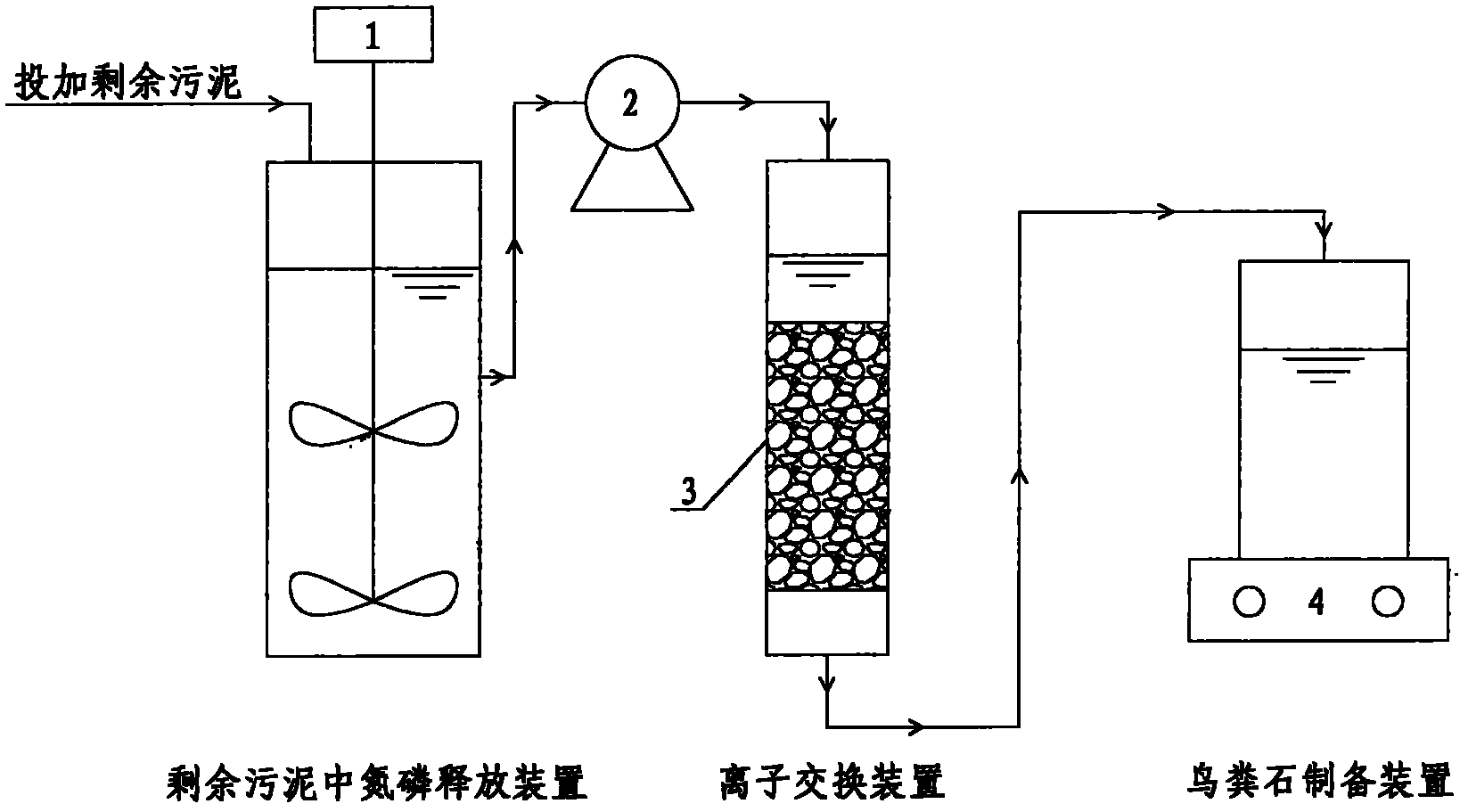

Image

Examples

Embodiment Construction

[0020] Take a sewage treatment plant (using A 2 / O process) return the remaining sludge in the sludge pumping station, put it in the nitrogen and phosphorus release device in the remaining sludge, and control the stirring speed in the range of 70-90r / min (at this time, the remaining sludge can be stirred evenly but not too much vortex), use 2mol / L HCl and NaOH solution to adjust the pH to be within the range of 3±0.2, and react at room temperature. After the reaction is carried out for 4 hours, the concentration of ammonia nitrogen, orthophosphate, and calcium and magnesium ions are respectively 239.2 mg / L, 128mg / L, 399.7mg / L and 196.2mg / L sludge supernatant. While releasing nitrogen and phosphorus in excess sludge, use 3% MgCl 2 The solution changes the purchased 001×7 strongly acidic cation exchange resin from the sodium type to the magnesium type. Then, take 40ml of modified magnesium-type strong acid cation exchange resin, put it into the exchange column, and use a peris...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com