Method and device for controlling spark-ignition direct injection engine

A technology of spark ignition type and control method, which is applied in the fields of spark ignition type direct injection engine control and spark ignition type direct injection engine, and can solve problems such as inability to ensure torque.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

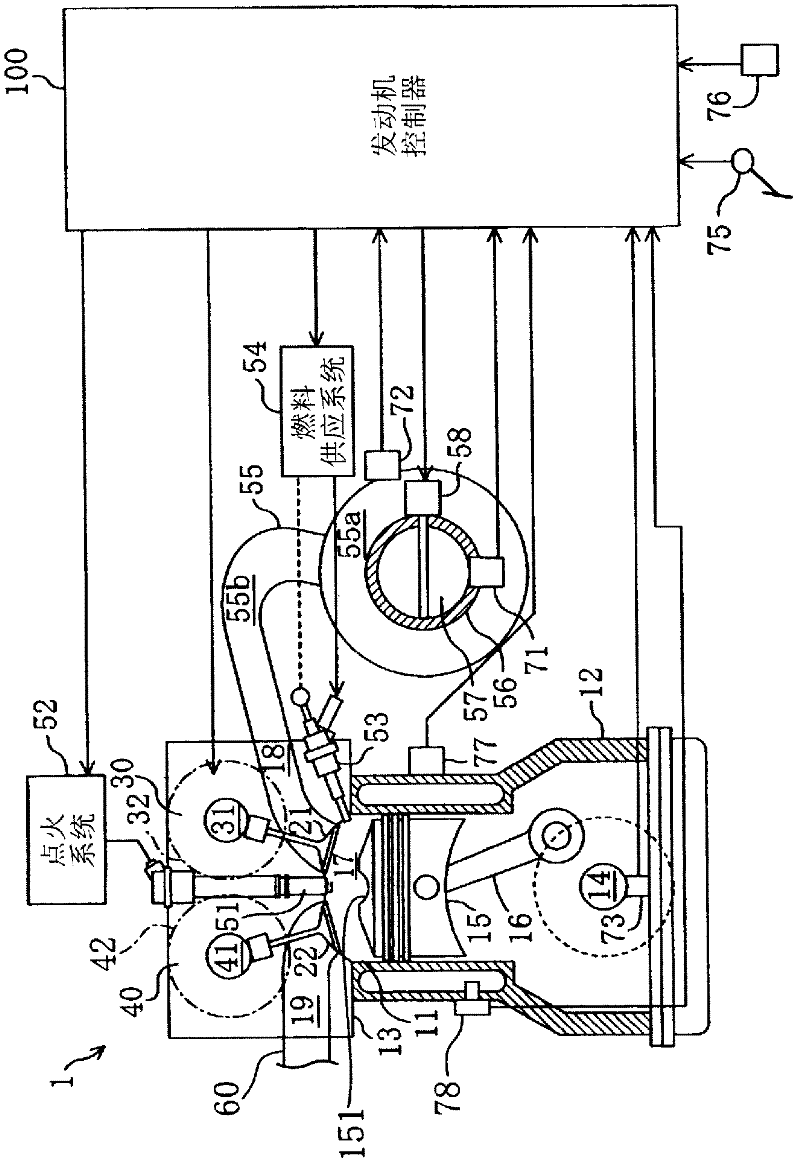

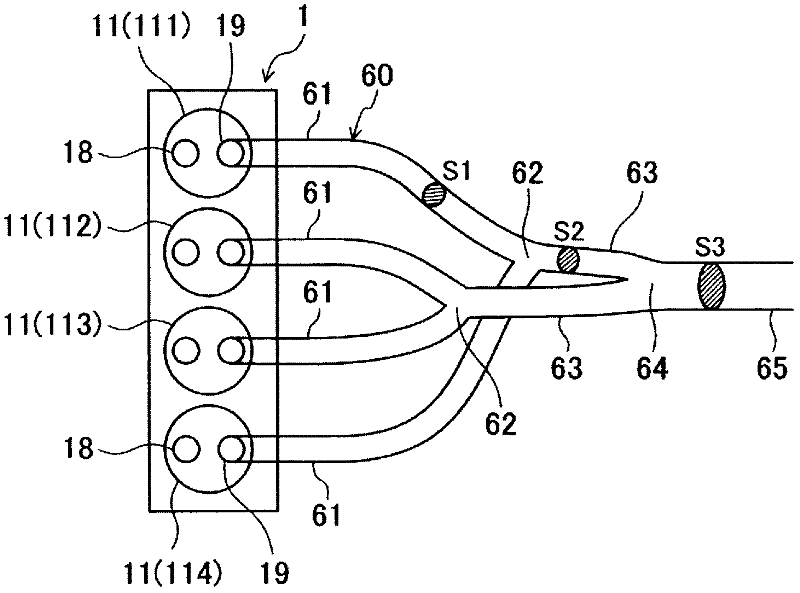

[0056] Hereinafter, a spark ignition direct injection engine and a control method thereof will be described based on the drawings. In addition, the description of the following preferred embodiments is merely an illustration in essence. Such as figure 1 As shown, a spark ignition direct injection engine (hereinafter simply referred to as "engine") includes an engine main body 1, various actuators attached to the engine main body 1, various sensors, and actuators controlled based on signals from the sensors. The engine controller 100. The geometric compression ratio of the engine body 1 of this engine is set to a high compression ratio of 12 or more. In this high compression ratio engine, knocking tends to occur particularly in a specific operating region in the low-speed region, which is a high load region. Knocking is effectively suppressed, and the high torque of a high compression ratio engine can be realized.

[0057] The engine body 1 is a spark ignition internal comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com