Radio frequency noise de-embedding method

A technology of radio frequency noise and de-embedding, applied in the direction of electrical components, single semiconductor device testing, electric solid-state devices, etc., can solve problems such as spending more time, wasting silicon chip area, and troublesome testing, so as to reduce testing time and improve Test efficiency, cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

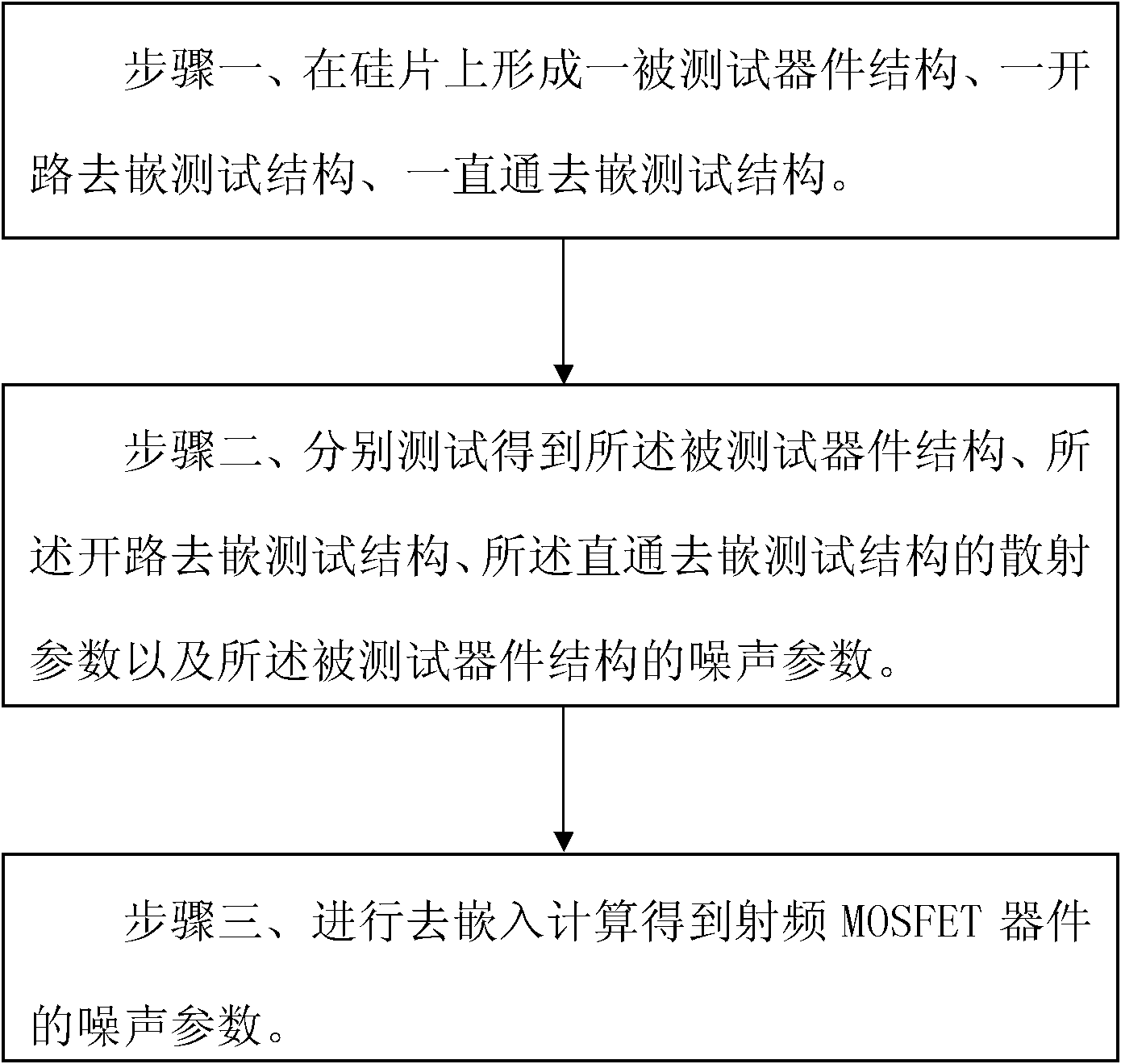

[0038] Such as image 3 As shown, it is a schematic flow chart of the open-through de-embedding method according to the embodiment of the present invention; the open-through de-embedding method according to the embodiment of the present invention includes the following steps:

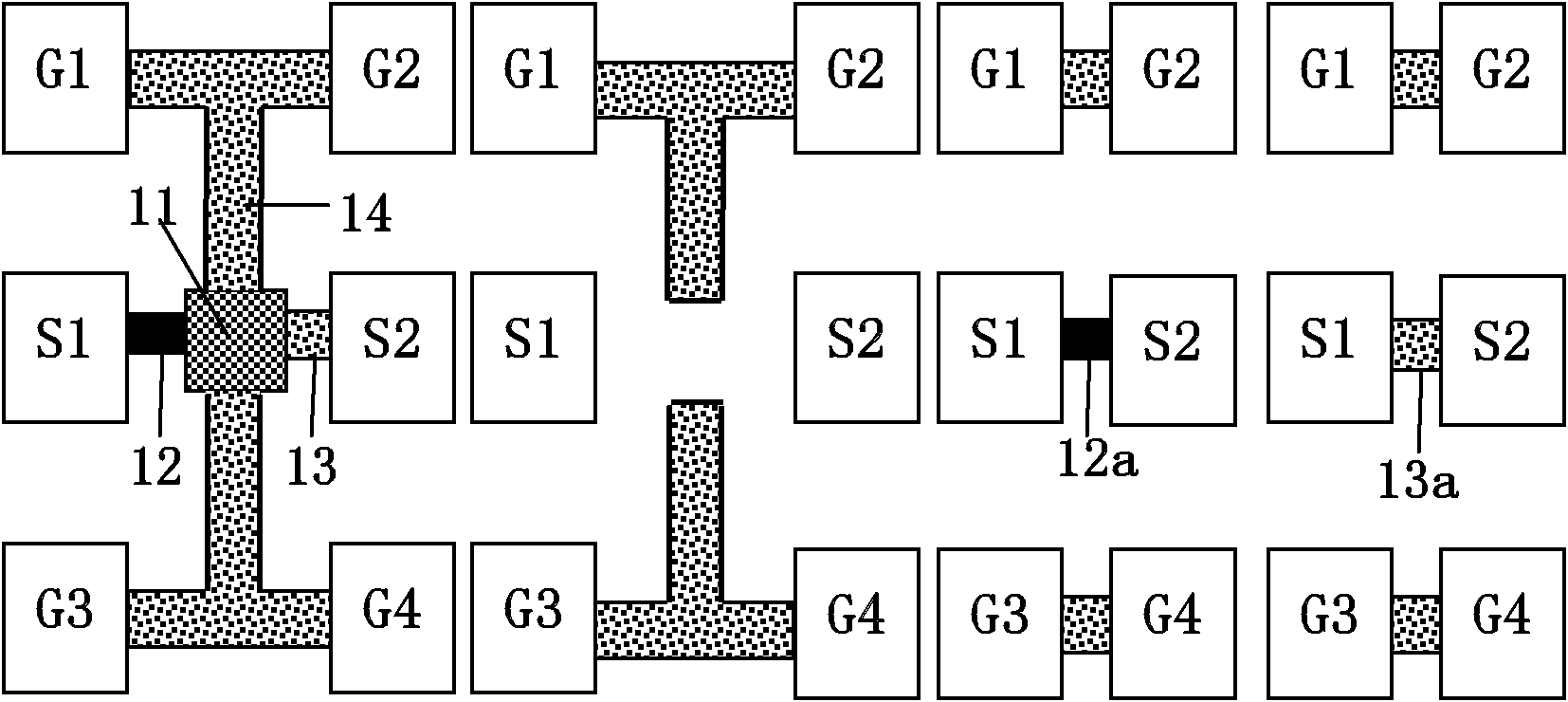

[0039] Step 1, such as Figure 4 As shown, a device under test structure 1, an open circuit de-embedding test structure 2, and a straight-through de-embedding test structure 3C are formed on a silicon chip; the device under test structure 1 includes a radio frequency device 11, a signal input pad S1, a signal output pad S2, four ground pads, the signal input pad S1 is connected to the input end of the radio frequency device 11 through a metal wire 12, the signal output pad S2 and The output terminal of the radio frequency device 11 is connected through the metal wire 2 13, and the four ground pads are connected to each other through the metal wire 3 14 and connected to the ground terminal of the radio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com