Drill

A drill bit and vertical technology, applied in twist drills, drill accessories, drilling/drilling equipment, etc., can solve the problems of high cost and increased cost, and achieve the effects of low cost, stable edge, and long drill life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

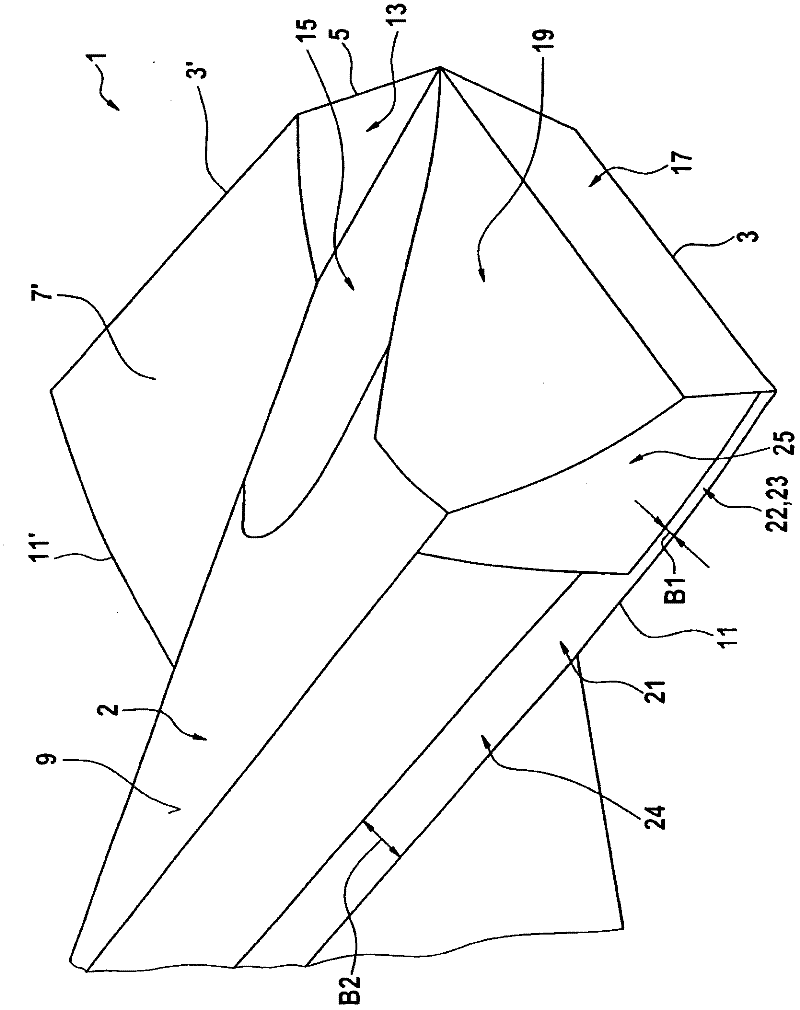

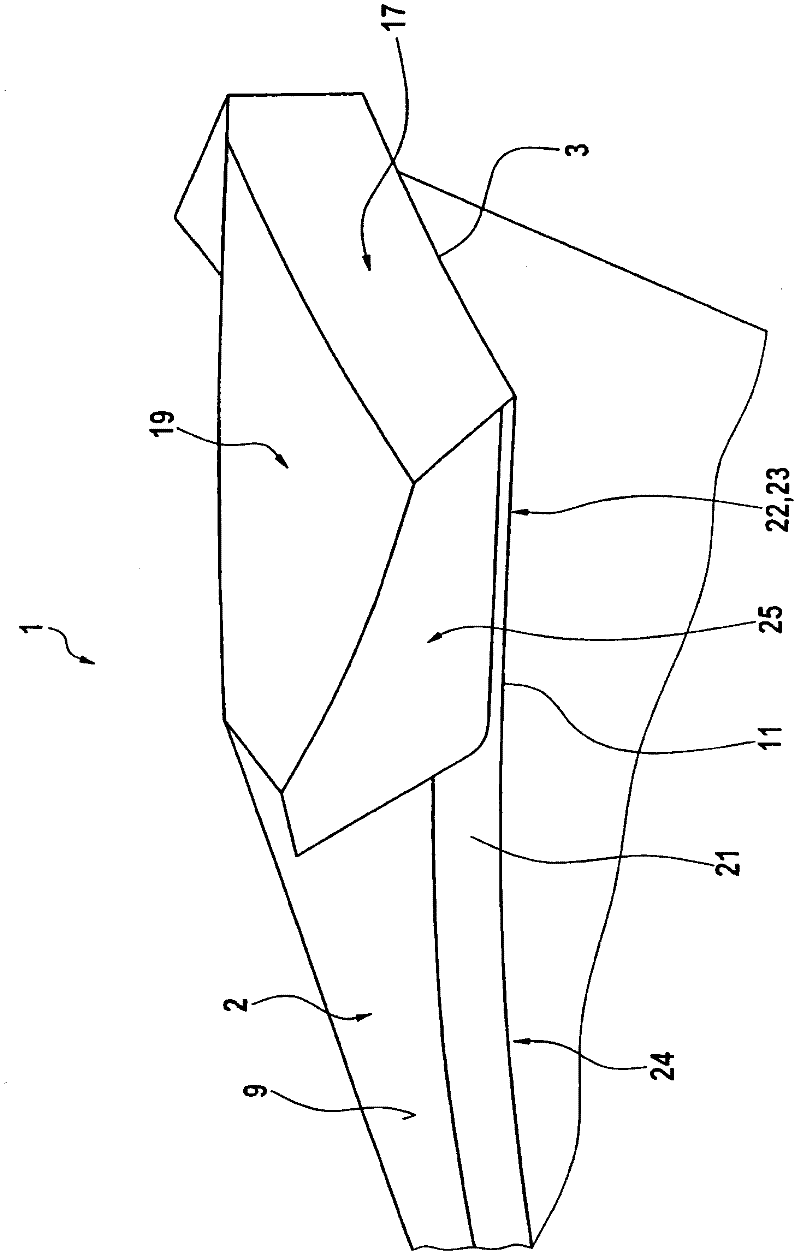

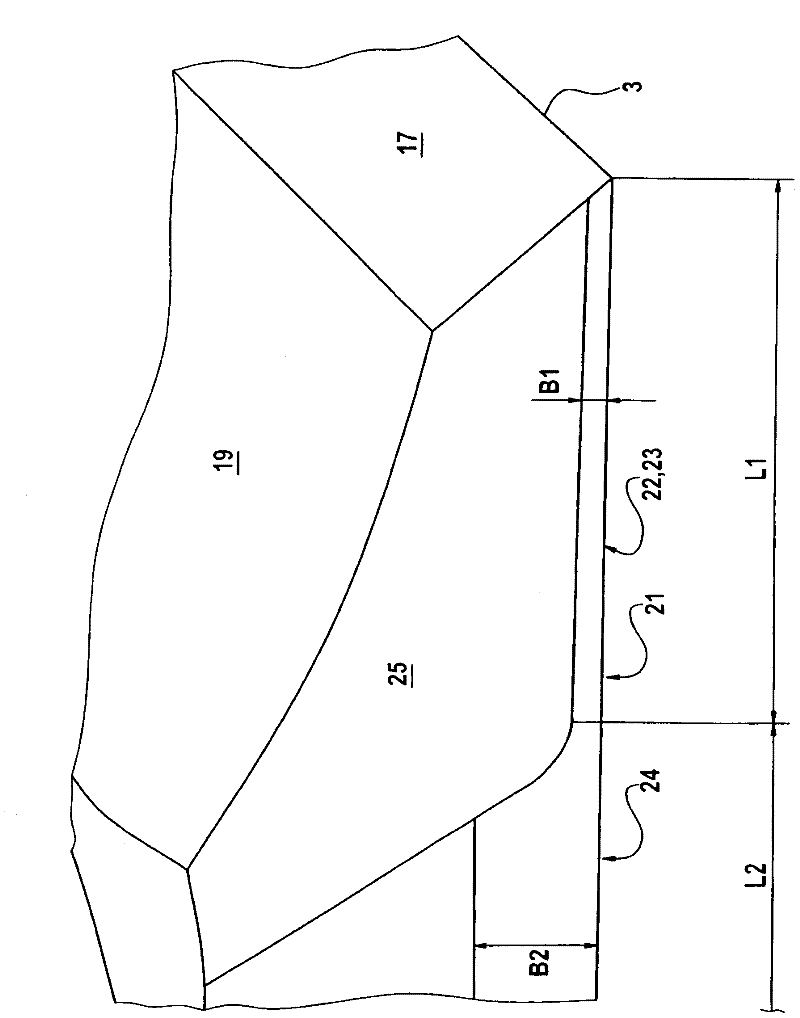

[0028] exist figure 1 A part of the drill bit 1 in the first embodiment is shown in a perspective view. Its viewing direction is the direction obliquely forward above the apex of the drill bit 1 .

[0029]In the exemplary embodiment shown here, the drill 1 is designed as an auger drill with a base body 2 on which a first main cutting edge 3 and a second main cutting edge arranged point-symmetrically with respect to the central axis of the drill 1 are provided. Edge 3'. In this exemplary embodiment, the two main cutting edges 3 , 3 ′ are preferably connected to each other by a chisel edge 5 extending through the central axis. The two main cutting edges 3 , 3 ′ are preferably arranged parallel to a diameter line running through the central axis, as seen in the direction of the end face of the drill 1 . These main cutting edges have an angle with respect to each other, commonly referred to as the apex angle, which is less than 90°. Therefore, the bit end with the main cutting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com