Reconstruction processing method of cut stems

A processing method and technology of cut stems, applied in the field of cut stem reprocessing, can solve the problems of high irritation, dull smoke, and opaque hair, and achieve the effects of improving taste, improving safety, and improving endoplasmic quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

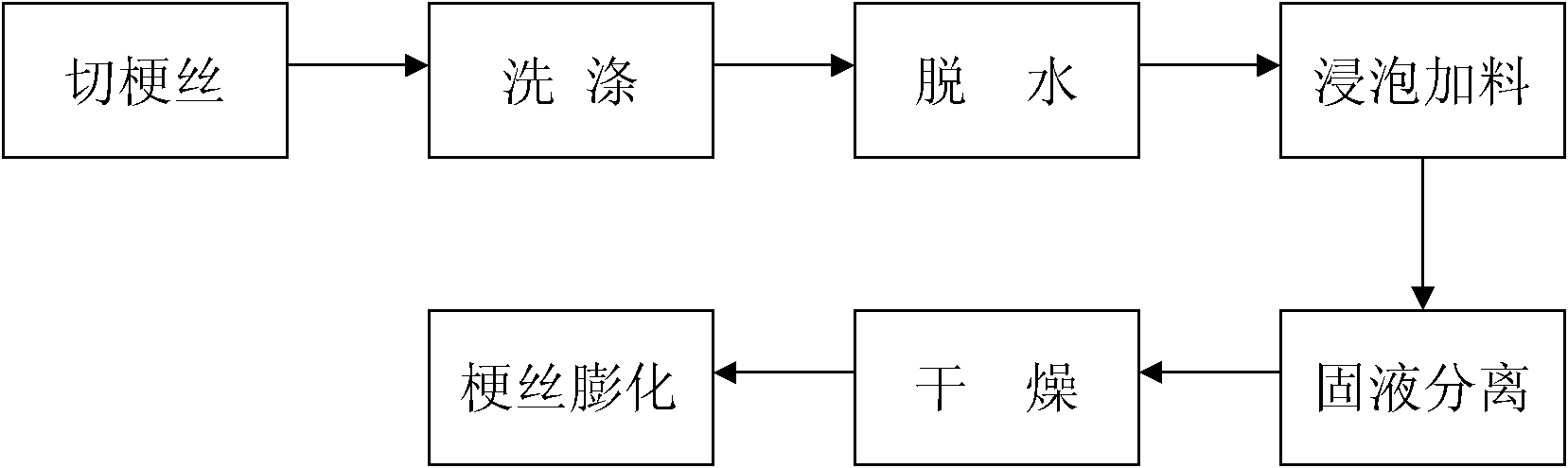

Method used

Image

Examples

Embodiment 1

[0027] 1. After cutting, the shredded stems (with a moisture content of about 32%) are quickly washed by a spiral stem washing machine. was washed out. The washing water temperature is normal temperature, the washing time is 5 minutes, and the solid-liquid ratio of the washing liquid is 1:3.

[0028] 2. The washed cut stems enter the continuous discharge centrifuge for dehydration. The continuous discharge centrifuge adopts a horizontal structure with a rotation speed of 3000 rpm and a centrifugation time of 5-10 min. Centrifuge output moisture 75%.

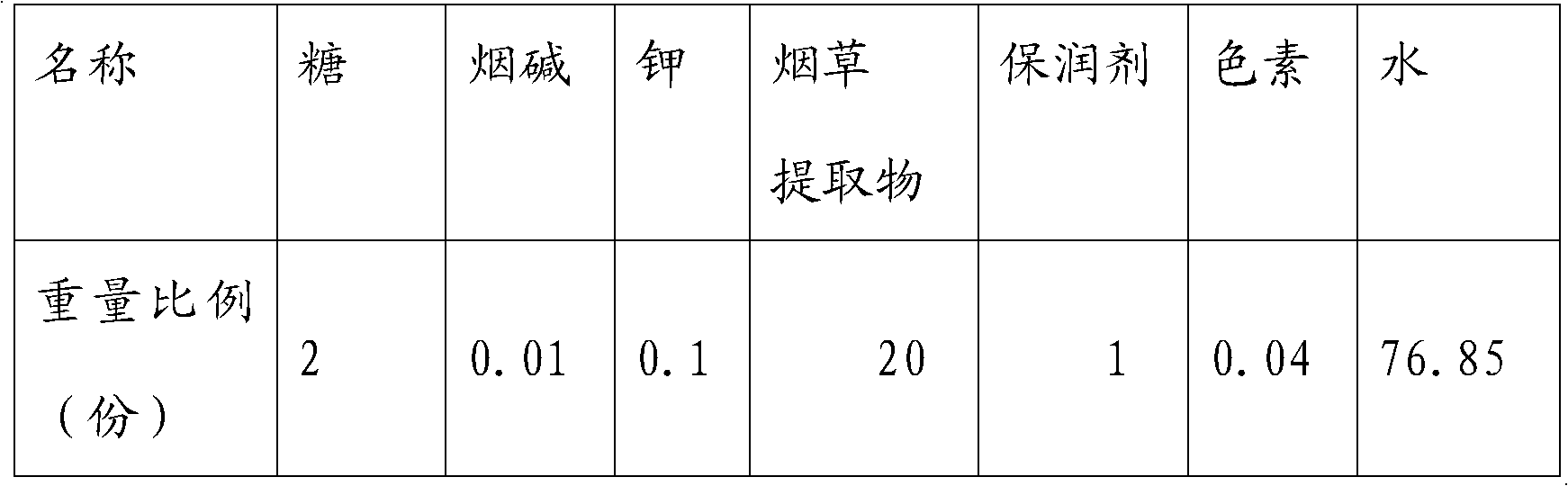

[0029] 3. The solid-to-liquid ratio of the soaking material is 1:5, the soaking time is 10 minutes, and the mixing ratio of the soaking process is:

[0030]

[0031] 4. The solid-liquid separation adopts a continuous discharge centrifuge, the centrifugation time is 5-10 minutes, and the rotation speed is 3000 rpm. After centrifugation, the feed liquid is refluxed and some new materials are added. After centrifugation, the w...

Embodiment 2

[0035] 1. After cutting, the shredded stems (with a moisture content of about 32%) are quickly washed by a spiral stem washing machine. was washed out. The washing water temperature is 25°C, the washing time is 5 minutes, and the solid-liquid ratio of the washing liquid is 1:4.

[0036] 2. The washed cut stems enter the continuous discharge centrifuge for dehydration. The continuous discharge centrifuge adopts a horizontal structure with a rotation speed of 3000 rpm and a centrifugation time of 5-10 min. The moisture content of the centrifuge output is 75%;

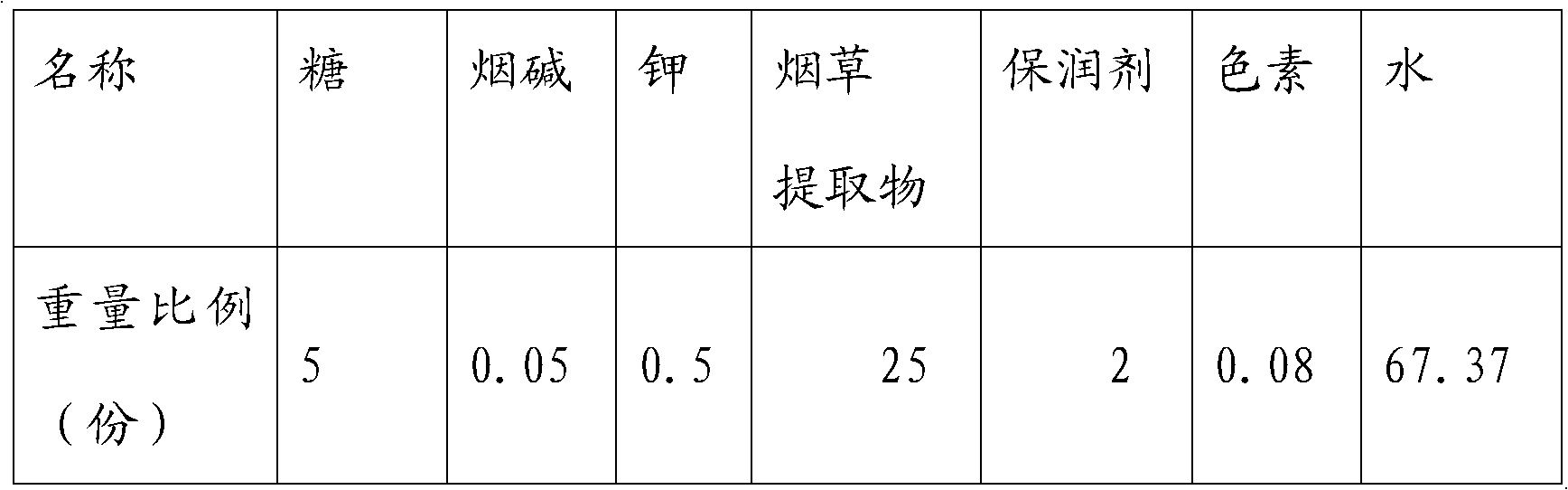

[0037] 3. The solid-to-liquid ratio of the soaking material is 1:4, the soaking time is 15 minutes, and the mixing ratio of the soaking process is:

[0038]

[0039] 4. The solid-liquid separation adopts a continuous discharge centrifuge, the centrifugation time is 5-10 minutes, and the rotation speed is 3000 rpm. After centrifugation, the feed liquid is refluxed and some new materials are added. After centrifugatio...

Embodiment 3

[0043] 1. After cutting, the shredded stems (with a moisture content of about 32%) are quickly washed by a spiral stem washing machine. was washed out. The washing water temperature is 30°C, the washing time is 3 minutes, and the solid-liquid ratio of the washing liquid is 1:6.

[0044] 2. The washed cut stems enter the continuous discharge centrifuge for dehydration. The continuous discharge centrifuge adopts a horizontal structure with a speed of 3000 rpm and a centrifugation time of 5 to 15 minutes. The moisture content of the centrifuge output is 75%;

[0045] 3. The solid-to-liquid ratio of the soaking material is 1:3, the soaking time is 15 minutes, and the mixing ratio of the soaking process is:

[0046]

[0047] 4. The solid-liquid separation adopts a continuous discharge centrifuge, the centrifugation time is 5-10 minutes, and the rotation speed is 3000 rpm. After centrifugation, the feed liquid is refluxed and some new materials are added. After centrifugation,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com