Novel least square support vector machine modeling method for thermal error of numerical control machine

A technology for support vector machines and numerically controlled machine tools, which is applied in electrical digital data processing, special data processing applications, instruments, etc. It can solve problems such as instability and non-normal distribution, and achieve low hardware requirements, good reliability, and improved self-efficacy. The effect of learning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

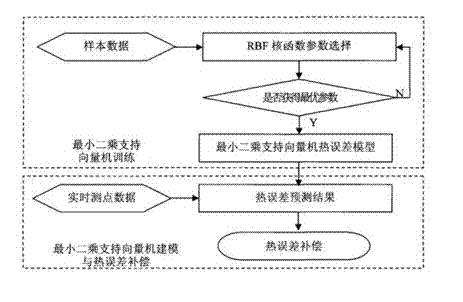

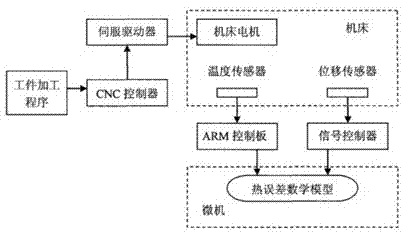

Method used

Image

Examples

Embodiment

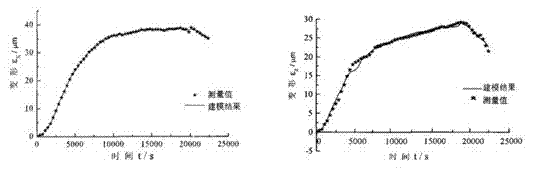

[0045] Thermal error modeling analysis of a XHK-714F CNC machining center. The thermal deformation data of the machine tool spindle is collected by a laser displacement sensor (LK-150H). The temperature field measurement system is composed of 14 intelligent temperature sensors, ARM7 embedded system platform (FS44BOXLII) and liquid crystal display unit. Under similar conditions, the temperature rise and the axial thermal error of the spindle were tested repeatedly during the continuous operation of the machining center for 6 hours and the shutdown for 1 hour, and a total of 70 sets of data were obtained.

[0046] According to the data acquisition, take the spindle temperature change T 0 , Spindle motor measuring point temperature rise T 1 , Ball screw measuring point temperature rise T 2 , Temperature rise T of column measuring point 3 , The temperature rise T of the machine bed measuring point 4 , ambient temperature T 5 , with the spindle axial error D 1 , Spin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com