Method and device for inhibiting eddy current of shield housings of shielded motor

A technology of electric motors and shielding sleeves, which is applied in the direction of electromechanical devices, electrical components, magnetic circuit shape/style/structure, etc., can solve problems such as shielding sleeve rupture, shielding sleeve eddy current power consumption, shielding sleeve deformation, etc., to achieve suppression of eddy current and Eddy current loss, simple structure and process, and the effect of reducing temperature deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific technical scheme of the present invention will be further described below in conjunction with accompanying drawing and embodiment:

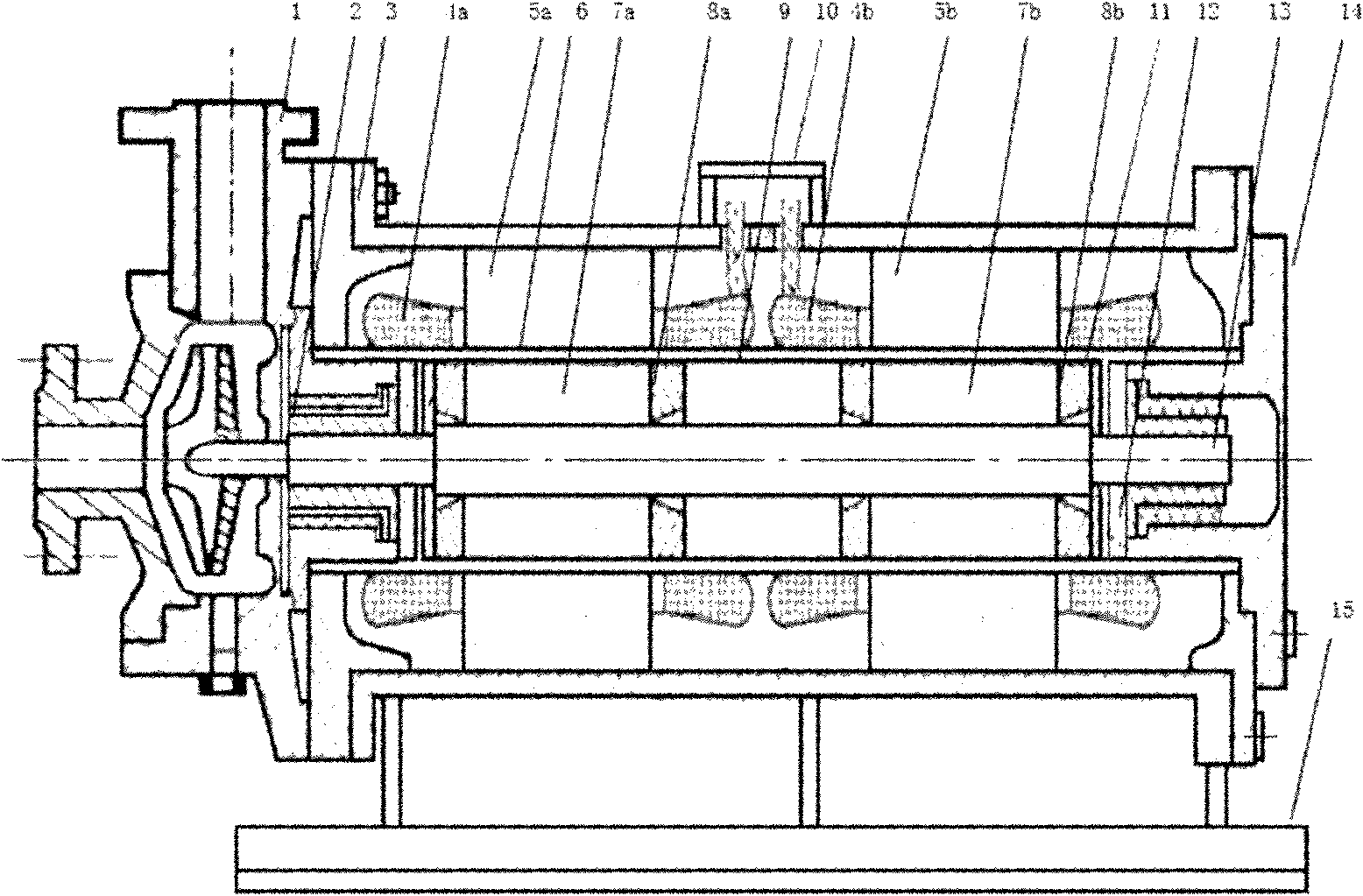

[0021] One embodiment of the present invention is a canned pump motor, such as figure 1 As shown, it mainly consists of pump body 1, bearing 2, housing 3, stator windings 4a and 4b, stator cores 5a and 5b, stator shielding sleeve 6, rotor cores 7a and 7b, rotor windings 8a and 8b, rotor shielding sleeve 9, Junction box 10 , rotor shielding end plate 11 , thrust disc 12 , rotating shaft 13 , end cover 14 and machine base 15 constitute.

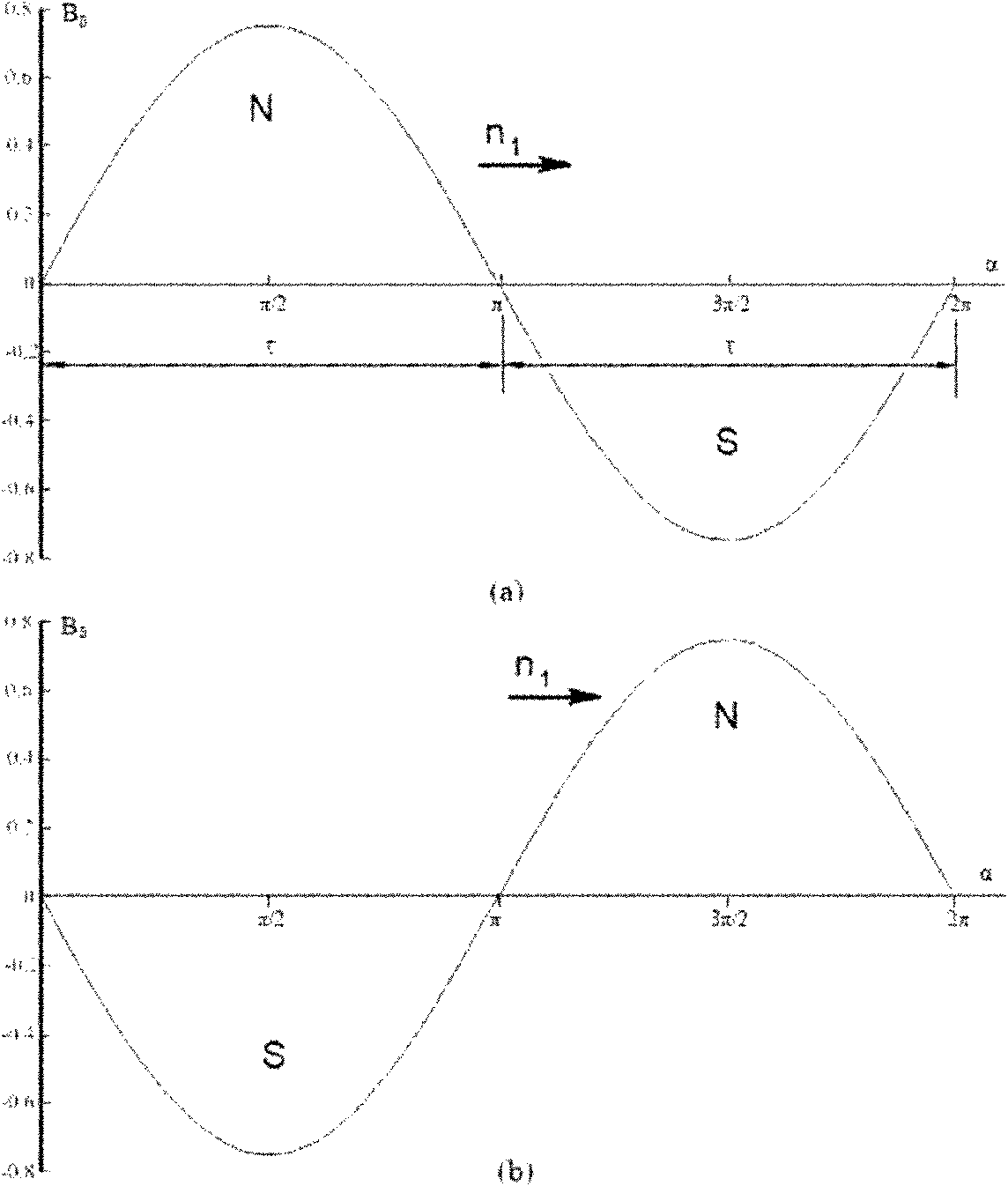

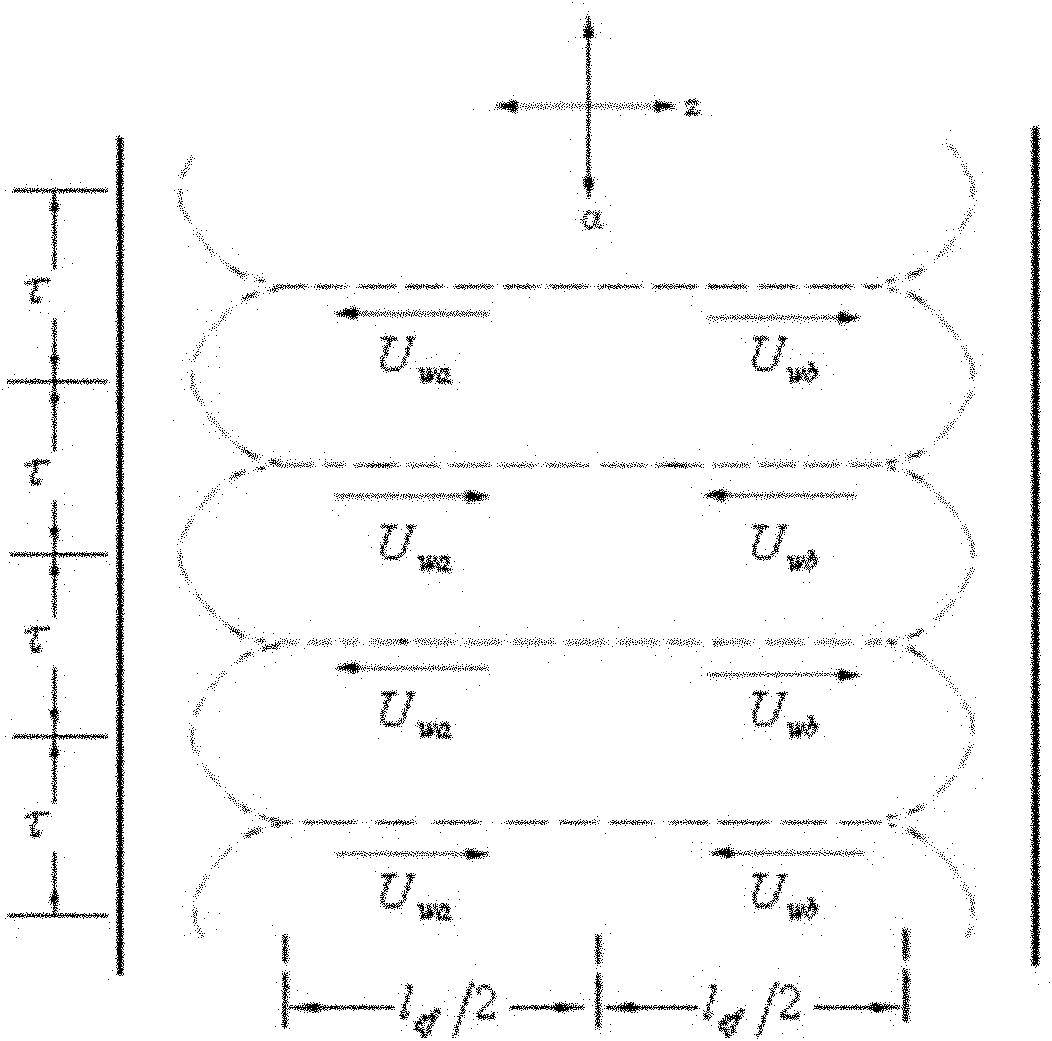

[0022] The stator windings 4a and 4b are identical in structure, wire material, wire specification, forming size and connection mode, and the corresponding phase windings of the stator windings 4a and 4b are staggered by a pole pitch τ=πD in the circumferential direction i1 / (2p), that is, the axis of the stator winding 4a and the axis of the corresponding phase winding of the stator winding 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com