Method for manufacturing wavelength conversion element

A technology of wavelength conversion element and manufacturing method, which can be applied in nonlinear optics, instruments, optics, etc., and can solve problems such as output instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

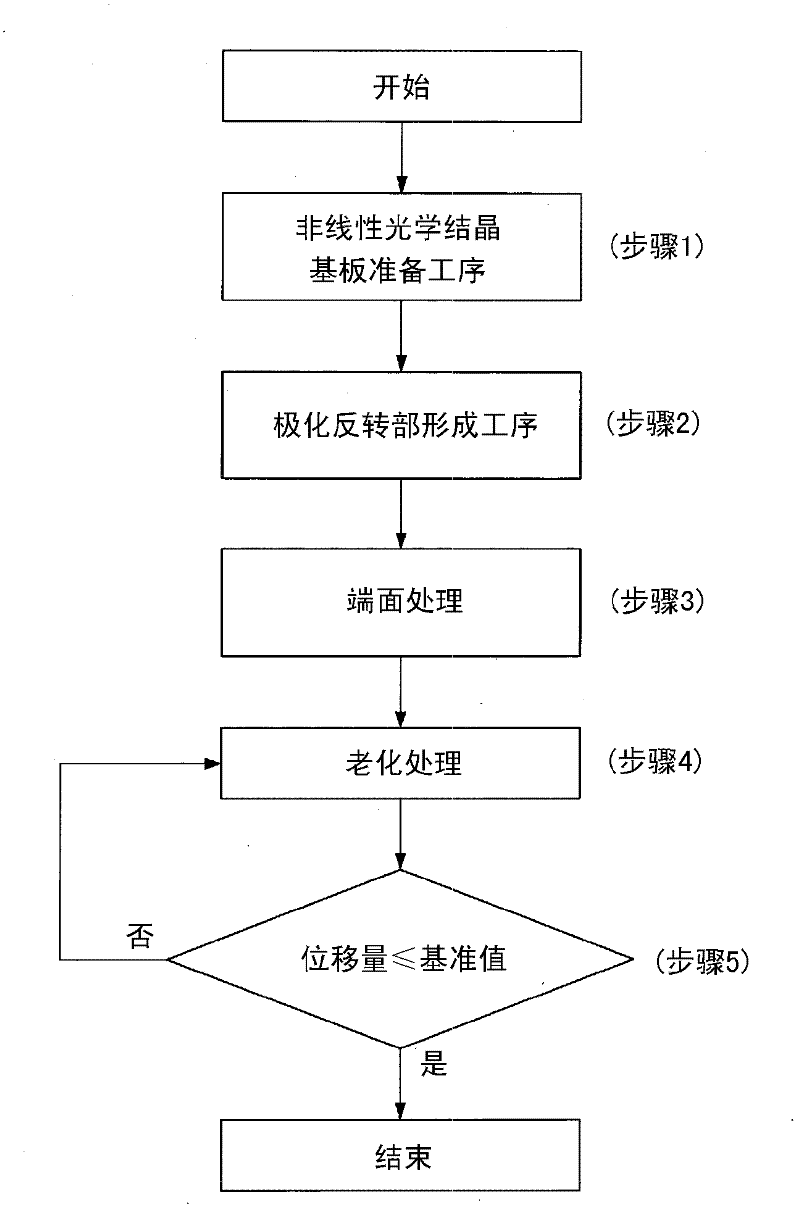

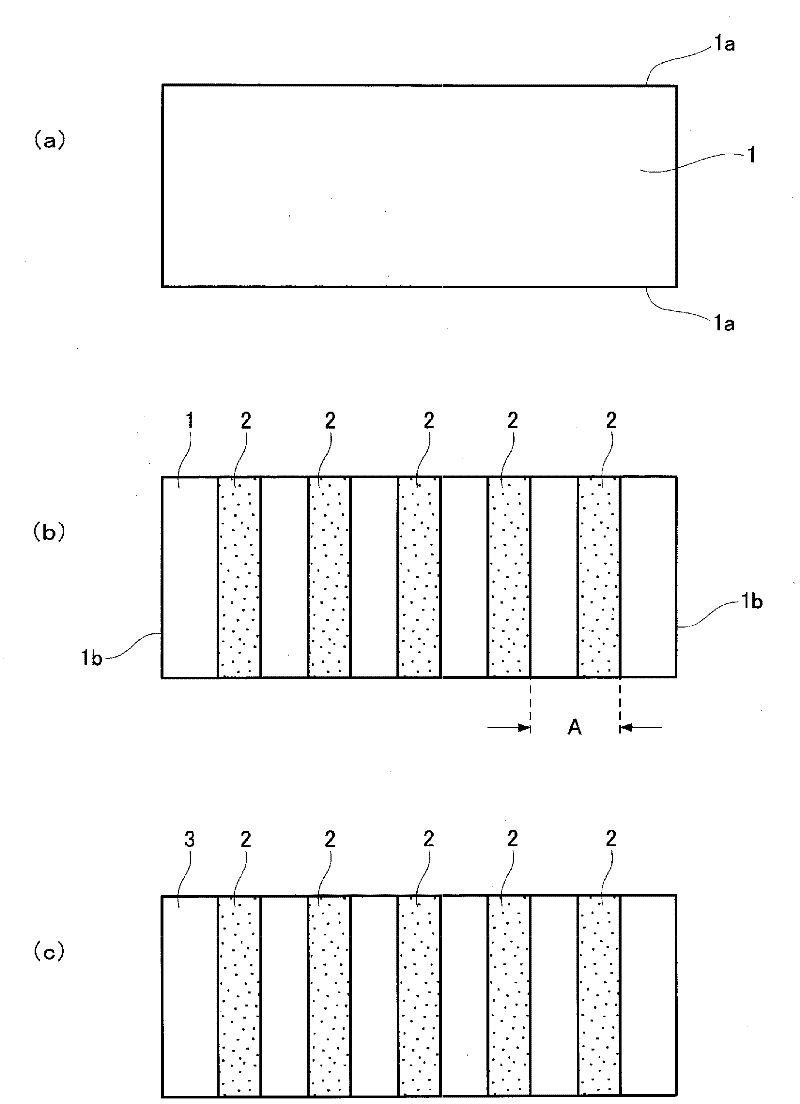

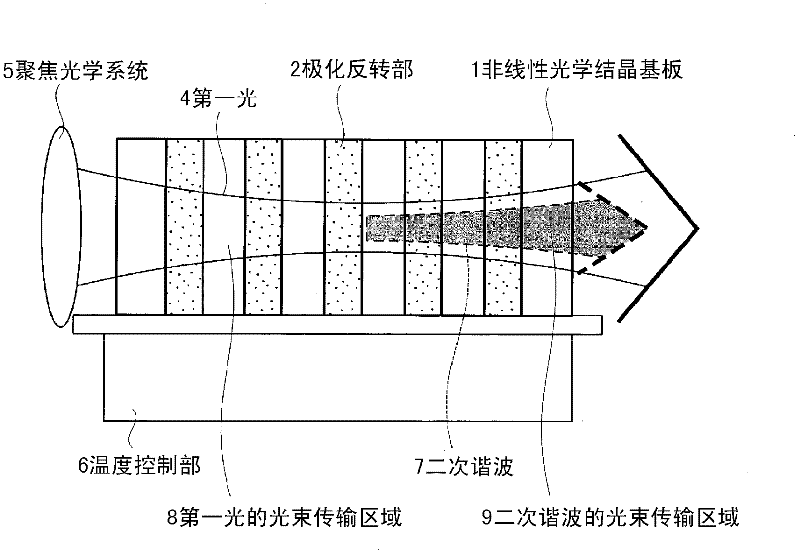

[0042] First, use Figure 1 to Figure 7 , the method of manufacturing the wavelength conversion element according to Embodiment 1 of the present invention will be described.

[0043] figure 1 It is a flowchart showing the manufacturing method of the wavelength conversion element in Embodiment 1. in addition, figure 2 It is a process sectional view showing the manufacturing method of the wavelength conversion element in Embodiment 1, figure 2 (a) shows a cross-sectional view of a nonlinear optical crystal substrate used as a material of a wavelength conversion element ( figure 1 step 1) in the figure 2 (b) shows the step of forming the polarization inversion part ( figure 1 The cross-sectional view after step 2) in figure 2 (c) means after the aging process ( figure 1 Sectional view after step 3) in . image 3 A cross-sectional view illustrating aging treatment in Embodiment 1 is shown.

[0044] correspond figure 1 Each of the shown steps describes the manufacturi...

Embodiment approach 2

[0095] Next, a method of manufacturing the wavelength conversion element according to Embodiment 2 of the present invention will be described.

[0096] Figure 8 A cross-sectional view illustrating an aging step in the method of manufacturing the wavelength conversion element 3 in the second embodiment is shown.

[0097] The difference from the first embodiment described above is that in the aging step in the manufacturing method of the wavelength conversion element 3, the nonlinear optical crystal substrate 1 is irradiated with the first light 4 having the same wavelength as the fundamental wave, and the second light having the same wavelength as the fundamental wave. The second light 10 with the same harmonic wave makes the first light 4 and the second light 10 incident in parallel with respect to the transmission direction, and the change amount of the phase matching temperature per unit time of the nonlinear optical crystal substrate 1 reaches a predetermined Irradiate un...

Embodiment approach 3

[0103] Next, a method of manufacturing the wavelength conversion element according to Embodiment 3 of the present invention will be described.

[0104] Figure 9 A cross-sectional view illustrating an aging step in the method of manufacturing the wavelength conversion element 3 in Embodiment 3 is shown.

[0105] The difference from Embodiment 2 above is that in the aging process in the manufacturing method of the wavelength conversion element 3, the nonlinear optical crystal substrate 1 is irradiated with the first light 4 having the same wavelength as the fundamental wave, and the second light having the same wavelength as the fundamental wave. The second light 10 with the same harmonic wave makes the first light 4 and the second light 10 intersect in the nonlinear optical crystal substrate 1, and the phase matching temperature of the nonlinear optical crystal substrate 1 changes in the amount per unit time to reach a predetermined Irradiate until the determined reference va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com