Rotating electric machine comprising an exciter

An exciter, rotary technology used in synchronous motors for single-phase current, control generators, synchronous generators, etc., to solve problems such as reduction in available power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

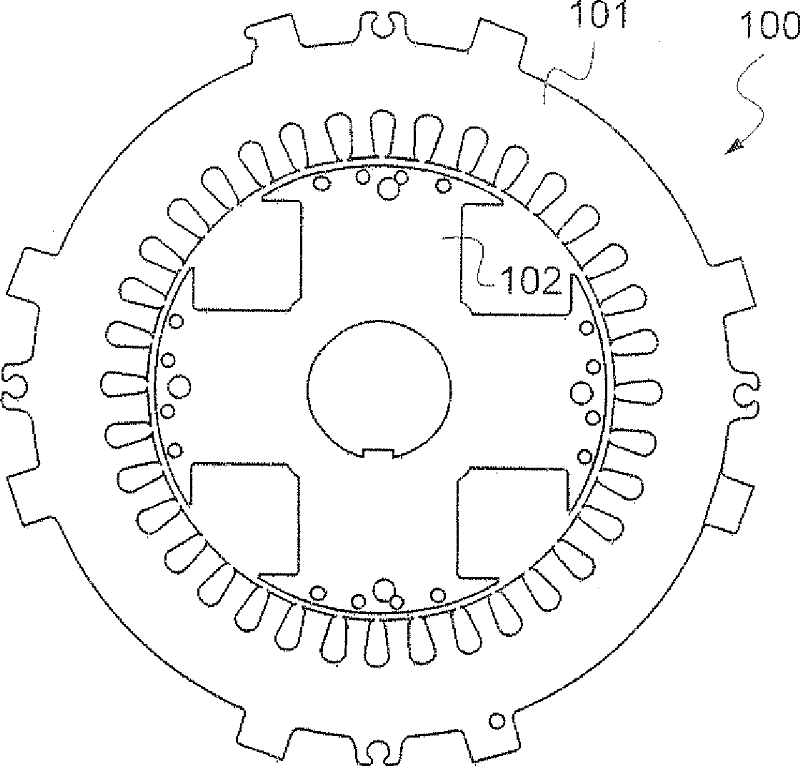

[0097] will refer to figure 2 A three-phase rotating electrical machine 1 according to an exemplary embodiment of the present invention will be described.

[0098] The three-phase electric machine 1 is, for example, a synchronous machine used as an alternator and has, for example, a power in the range between 5-1000 kVA.

[0099] In the example shown, the machine 1 comprises a stator yoke 2 and a rotor yoke 3 .

[0100] The stator yoke 2 and the rotor yoke 3 house the main electrical winding and the exciter electrical winding, respectively.

[0101] Such as figure 2 As can be seen in , the stator yoke 2 can comprise a plurality of slots 5 evenly distributed around the circumference. In the example described, the stator yoke 2 comprises twenty-four slots 5 , but the invention is not limited to a specific number of slots 5 .

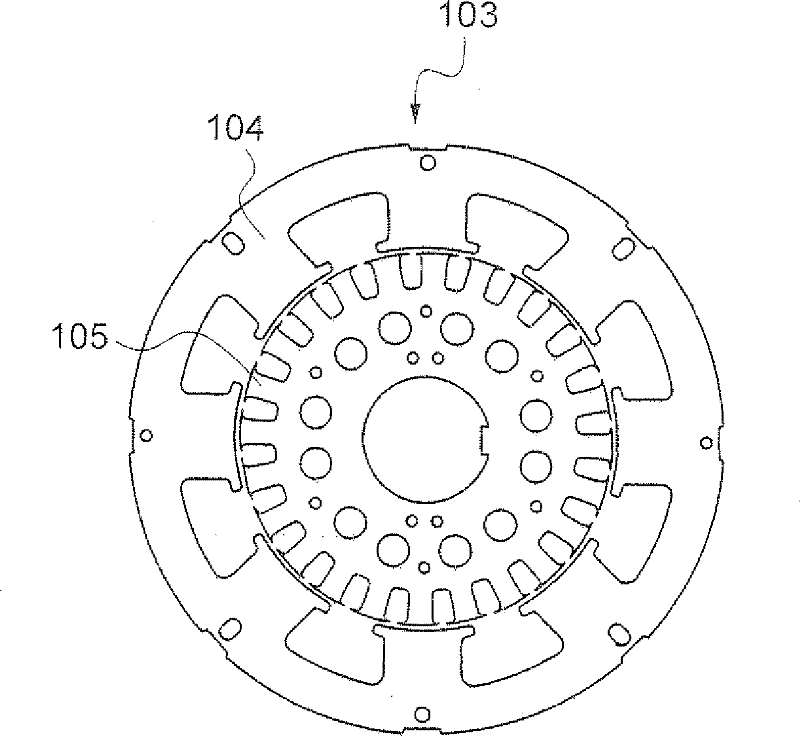

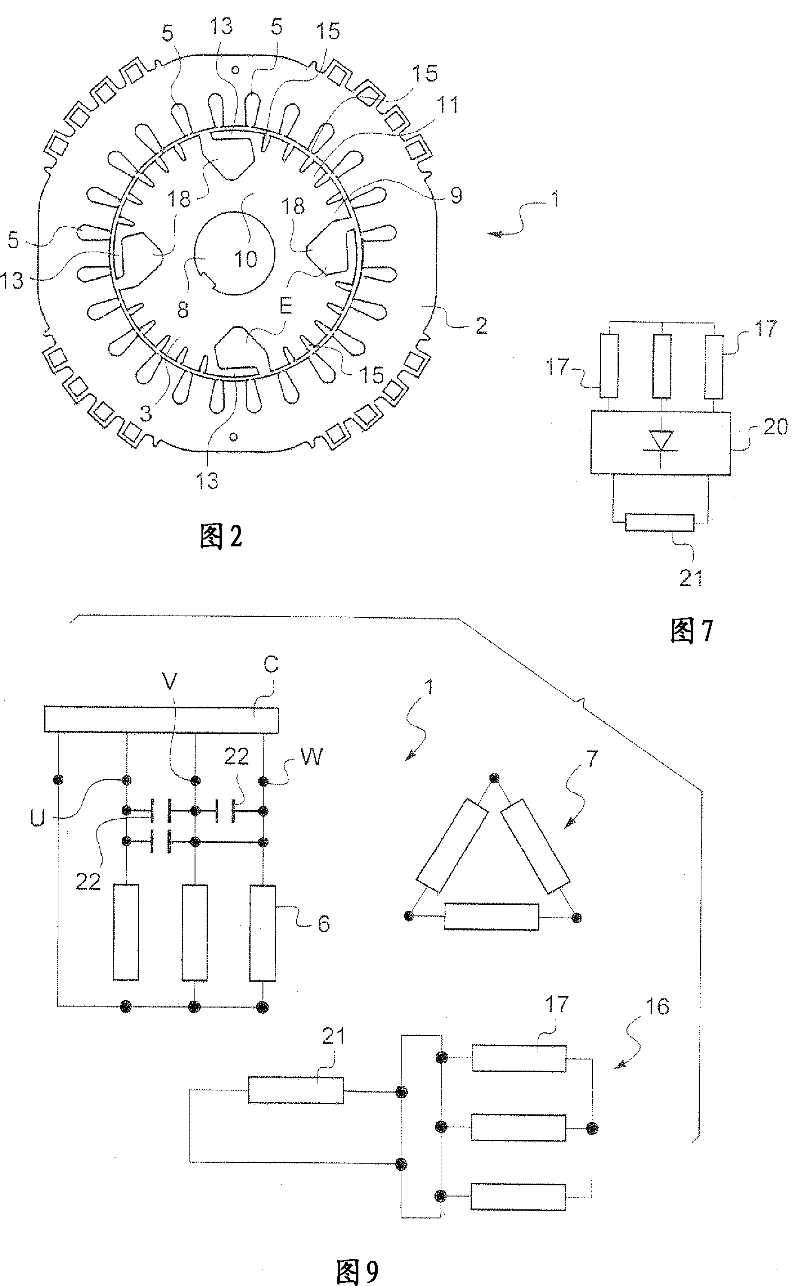

[0102] image 3 An example of a main armature winding 6 housed in a slot 5 is shown. image 3 , Figure 8 , Figure 12 and Figure 14 Shows the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com