Technology of in situ harmless treatment on waste drilling mud

A technology for harmless treatment and drilling mud, applied in chemical instruments and methods, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., can solve the problem of high transportation cost and treatment cost, supernatant Problems such as high pollutant concentration and inability to discharge on-site, etc., to achieve the effect of saving transportation costs, low costs, and low treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

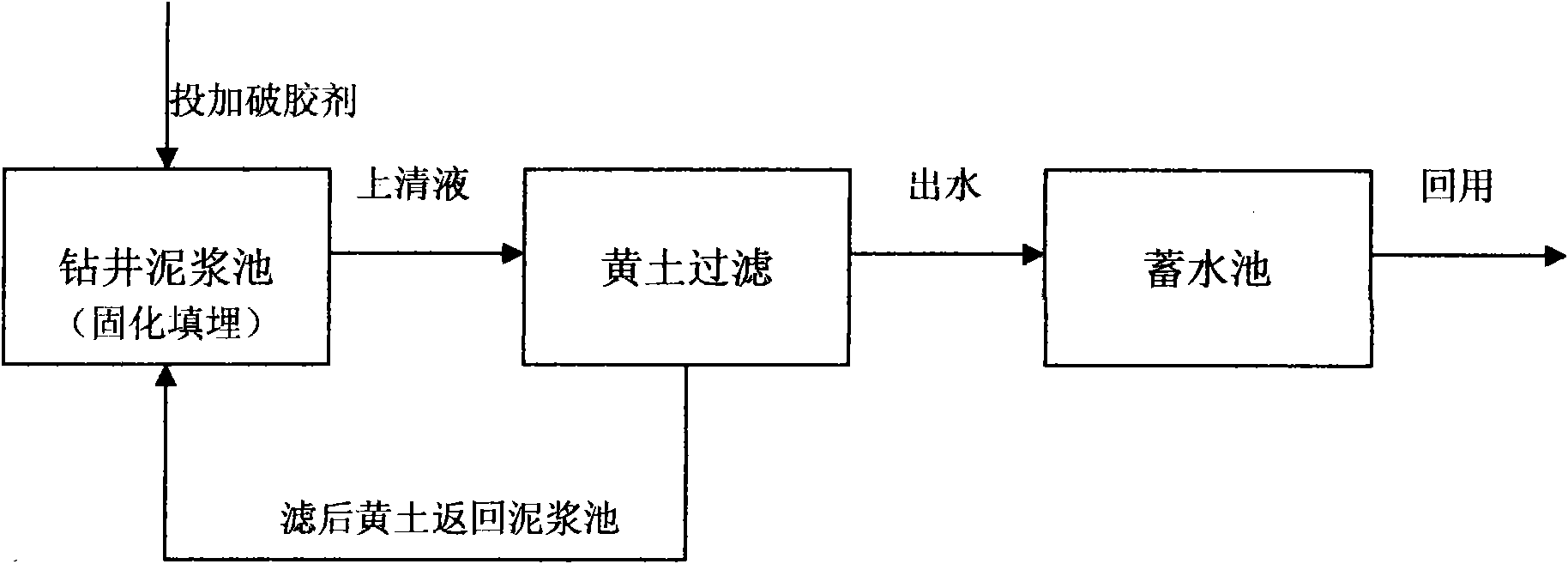

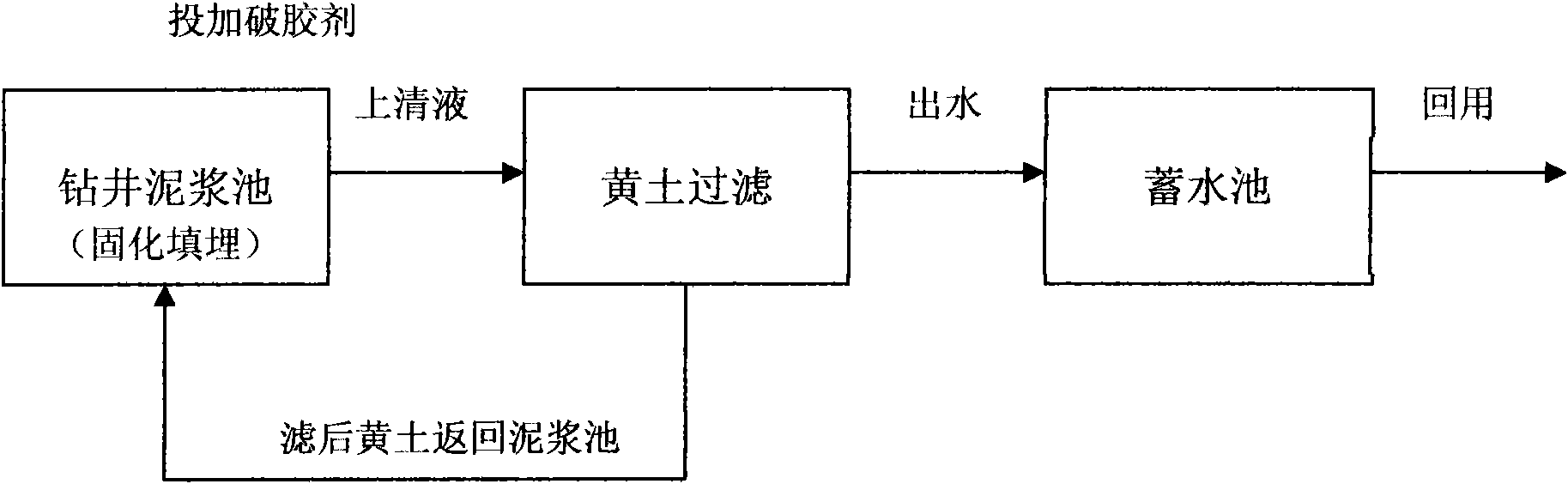

[0015] In order to clearly illustrate the technical features of this solution, the following will describe this solution through specific implementation modes and in conjunction with the accompanying drawings.

[0016] Lay plastic sheeting on the ground of the well site, and the plastic sheeting has a certain slope. Dig a reservoir at the lower end of the plastic sheet, and the volume of the pond is determined according to the volume of water in the drilling mud. The excavated soil is piled up on a plastic sheet and made concave at the top. Add gel breaker to the drilling mud pool. The gel breaker can be used with inorganic coagulant, organic coagulant, or combination of inorganic and organic, such as ferric chloride, polyaluminum chloride, polyacrylamide, etc. The quantity is determined according to the field test. After the agent is added, stirring is required to fully mix the agent and water to improve the effect of solid-liquid separation; an excavator or a water pump ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com