Construction method for oblique tunneling of rectangular pipe jacking machine in closed space

A technology of closed space, construction method, applied in the direction of filling, earth square drilling, mining equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

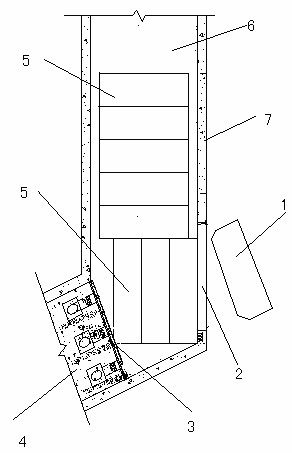

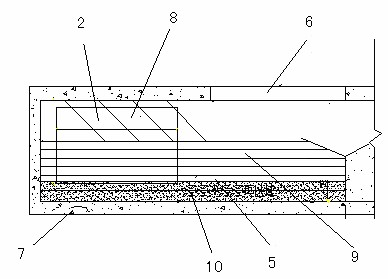

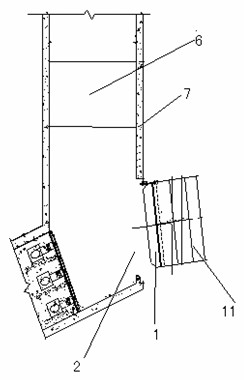

Examples

Embodiment Construction

[0007] Retaining wall construction:

[0008] In order to ensure that the receiving well is closed, a rigid retaining wall is used as the passage to close the receiving well. Easy backfilling work.

[0009] Receiving well backfill sand:

[0010] Ensure that the compactness of the bottom backfill and its height meet the requirements (to meet the compactness of the work of the rectangular pipe jacking machine translation after exiting the hole). Backfill with yellow sand according to the actual height of the hole of 1120mm. Backfill layer by layer according to the map. Use 0.2m 3 The excavator and manual work together to sprinkle water layer by layer and compact back and forth to ensure the compactness of the backfill.

[0011] Steel plate tiling:

[0012] After ensuring the compactness of the yellow sand at the bottom, 30mm thick steel plates are used to lay all over the yellow sand to form a steel platform receiving frame, which is also convenient for the translatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com