Flat-straight winding device of hollow fiber membrane

A fiber membrane, flat technology, applied in the field of hollow fiber membrane production, can solve the problems of inner arc and outer arc difference in membrane aperture, unevenness, etc., achieve good straightness, short membrane falling time, and save raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] specific implementation plan

[0021] The present invention will be further described below using the accompanying drawings and examples.

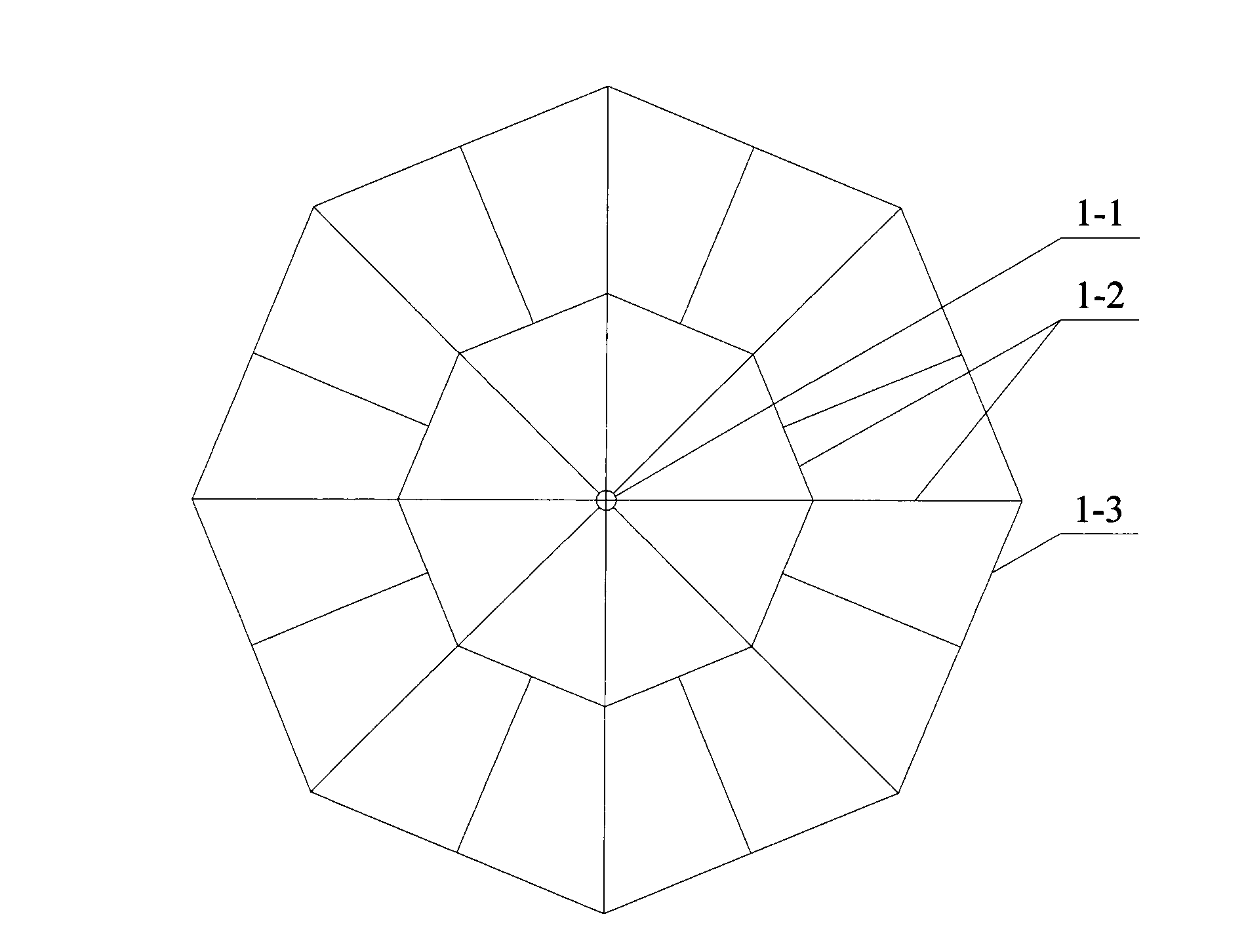

[0022] refer to figure 1 , the straight winding of the present invention comprises the axle sleeve 1-1 of winding wheel disk, the skeleton 1-2 of winding wheel disk and the winding disk surface 1-3 are made up. Adopt tapered fit with axle in the axle sleeve 1-1 of coiling roulette. The skeleton 1-2 of winding roulette is to be welded with 304 stainless steel square pipe and winding axle sleeve 1-1. The winding disk surface 1-3 is formed by folding and pressing a 304 stainless steel plate, and is welded and fixedly connected with the skeleton 1-2 of the winding disk.

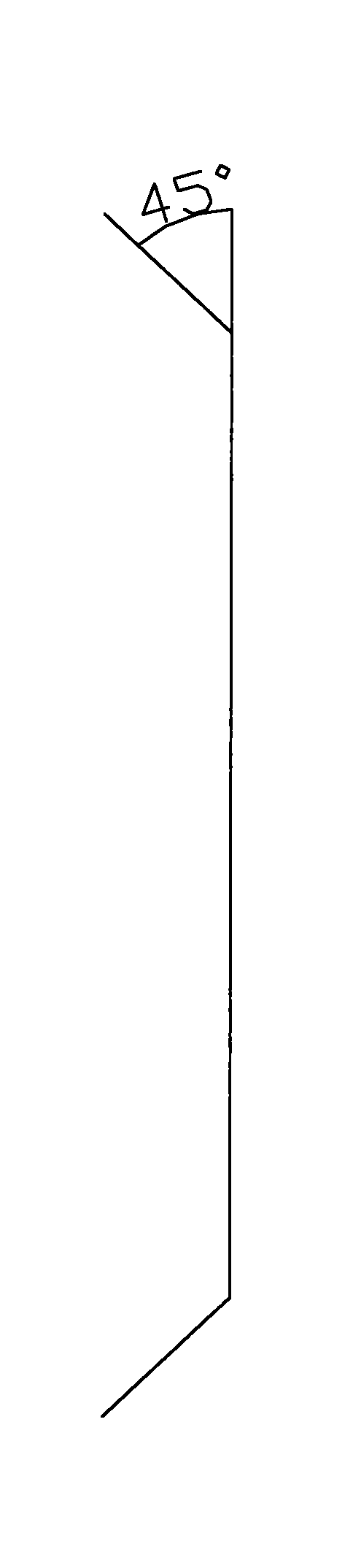

[0023] refer to figure 2 , the plan view of the winding disc surface of the present invention, the length of the hem on both sides is 10mm, and the angle is 45 degrees. The length of the disk depends on the length of the film required.

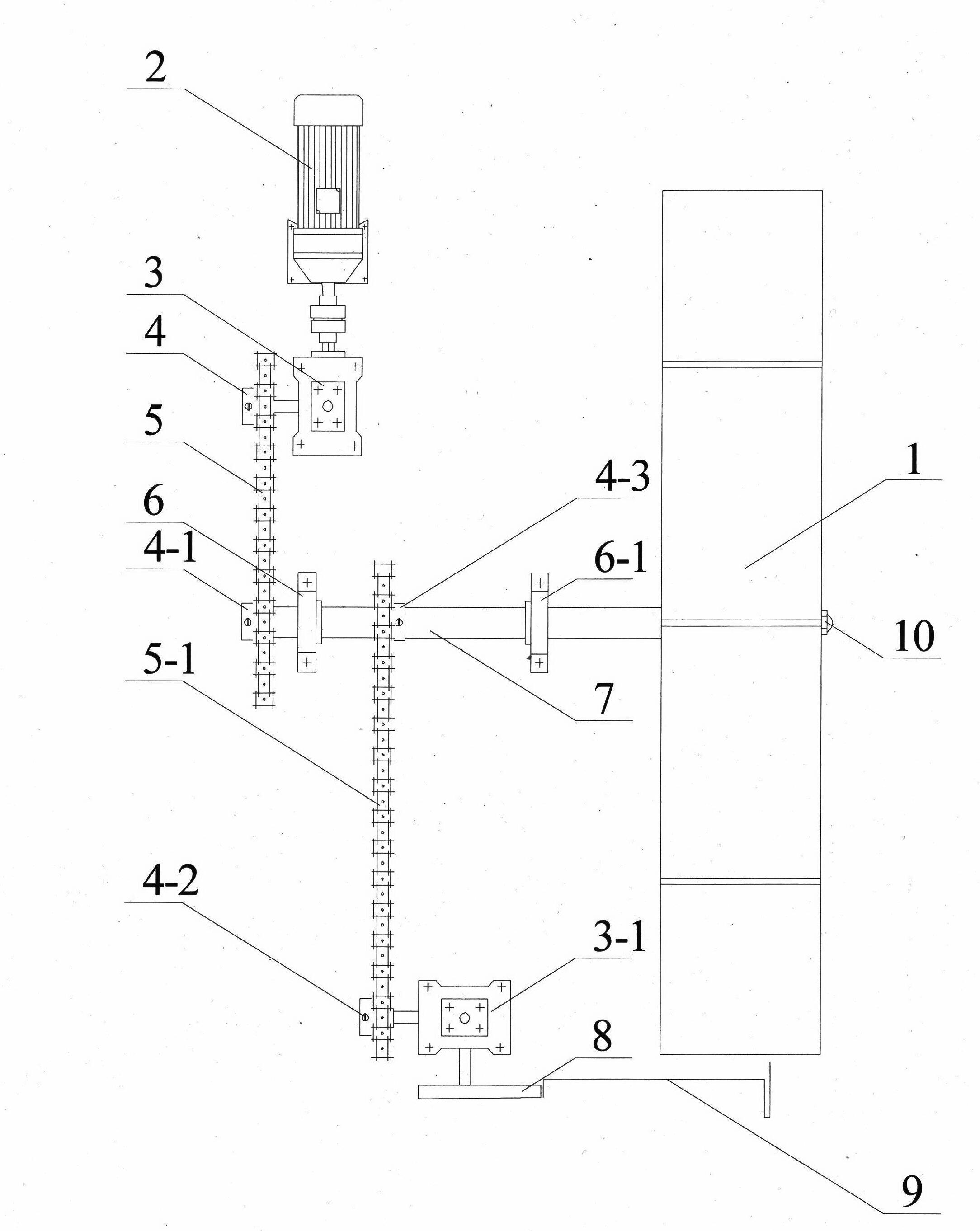

[0024] refer to image ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com