Method, device and equipment for colloid removal with laser

A laser and laser energy technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of insufficient cutting yield, time-consuming, etc., and achieve the effect of improving production efficiency and reducing production defect rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

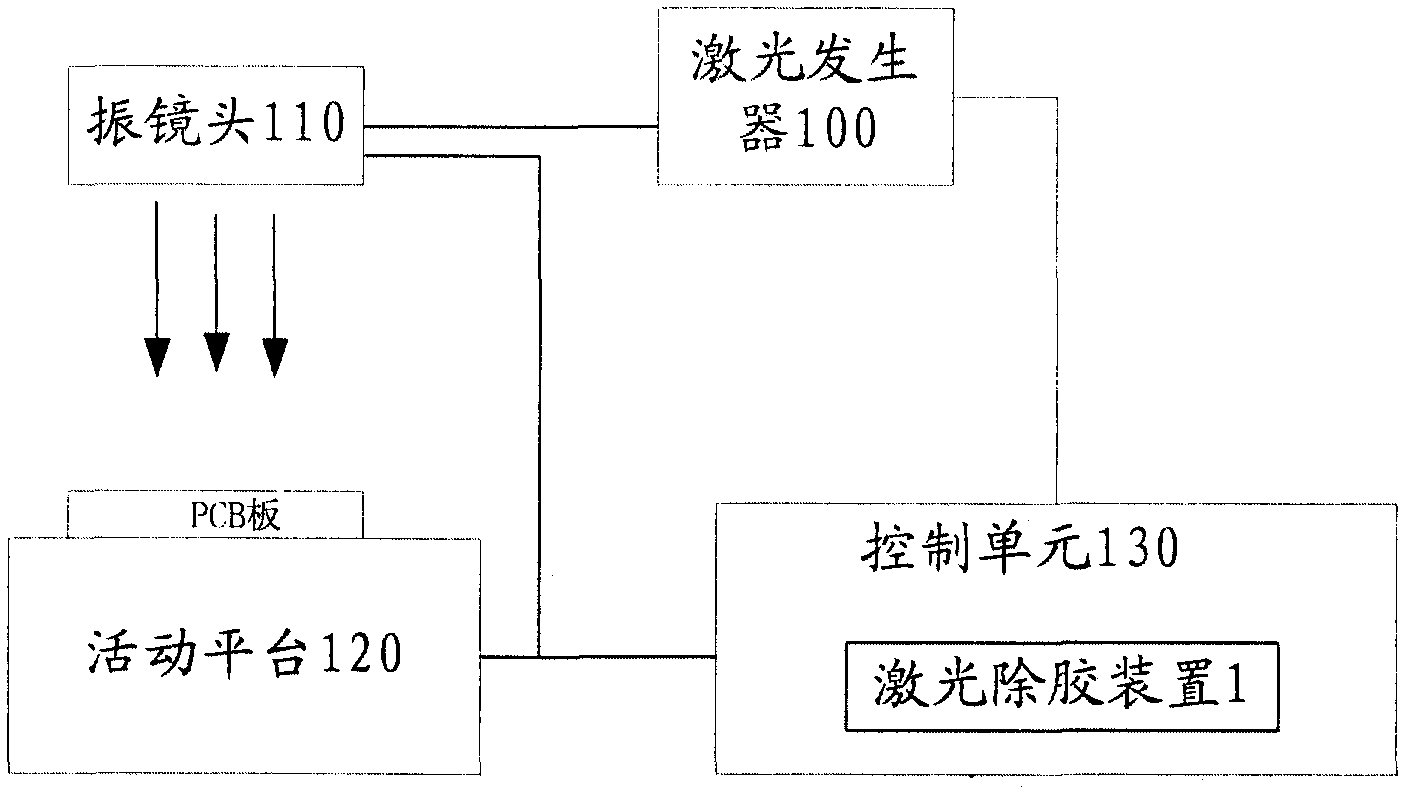

[0033] Laser processing technology is a technology that uses the characteristics of the interaction between the laser beam and the material to cut, weld, surface treat, drill, micro-process, and use it as a light source to identify objects, etc., for materials (including metals and non-metals). The largest field is laser processing technology. Laser processing systems include lasers, light guide systems, processing machine tools, control systems and detection systems.

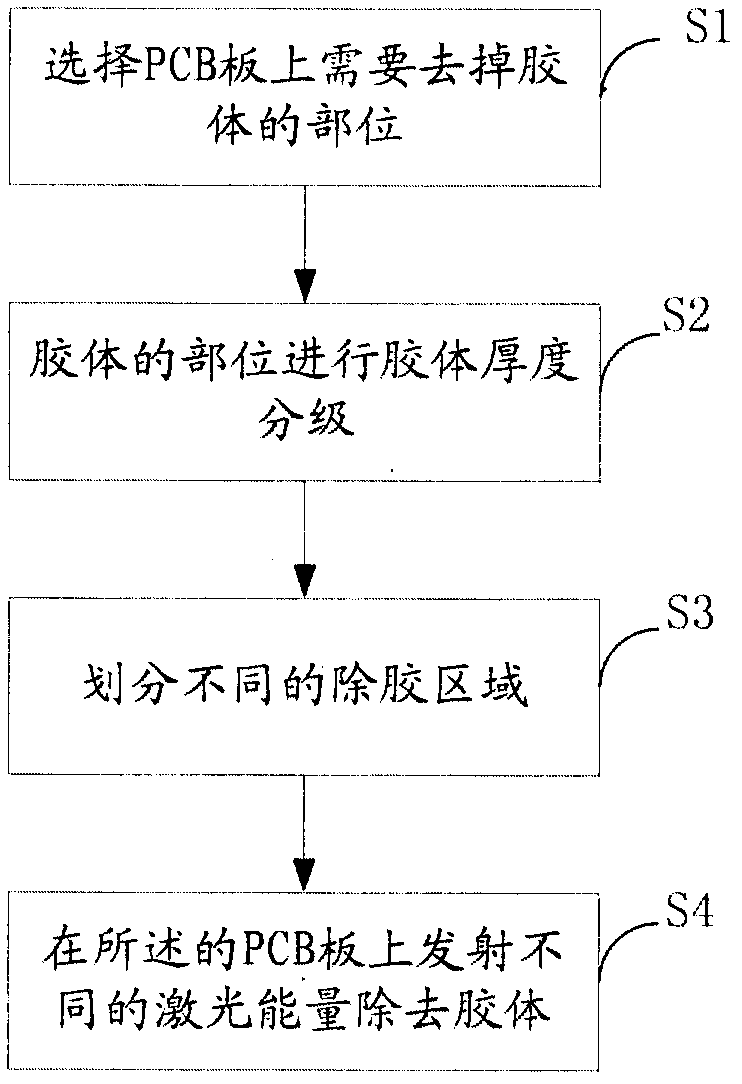

[0034] see figure 1 , a laser deglue method, comprising:

[0035] S1. Select the part on the PCB where the colloid needs to be removed;

[0036] When removing bad components, such as IC, the colloid still remains on the PCB, you can scan the colloid, take a photo and tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com