System for monitoring working state of boring rod in real time

A real-time monitoring system and working state technology, applied in manufacturing tools, metal processing equipment, measuring/indicating equipment, etc., can solve the problems of measuring vibration signals of boring tools, inability to use, etc., to overcome wiring difficulties, fast response speed, Strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] With reference to accompanying drawing, further illustrate the present invention:

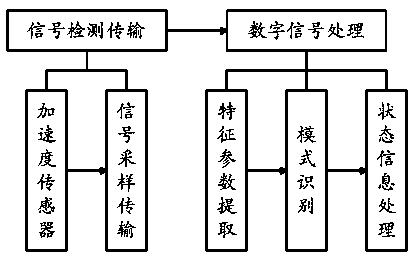

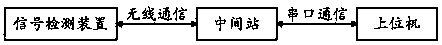

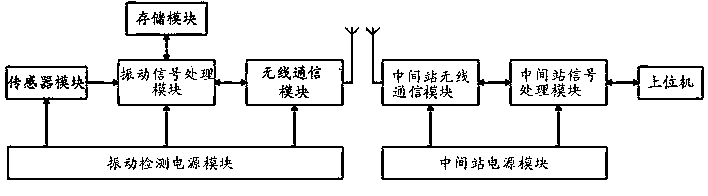

[0027] The real-time monitoring system of the working state of the boring bar includes a signal detection device fixed at the end of the boring bar for monitoring the vibration signal of the boring bar, a host computer for analyzing and processing the monitored vibration signal, and a connection between the signal detection device and the host computer. Intermediate station for inter-communication;

[0028] The control command sent by the upper computer is transmitted to the intermediate station, and the intermediate station sends the control command to the signal detection device through wireless communication, and receives the vibration signal sent by the signal detection device; the signal detection device sends the detected vibration signal through wireless communication To the intermediate station, the vibration signal is sent from the intermediate station to the host computer throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com