Method for producing anti-reflection coating of cover glass pipe of solar high-temperature heat collecting pipe and production line

A cover glass tube and production method technology, which is applied in the field of high-temperature solar collector tube manufacturing, can solve the problems of long-term pollution resistance, friction resistance, aging resistance, low degree of automation, and low film adhesion, and achieve good consistency and high efficiency. Competitive value, effect of solar transmittance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

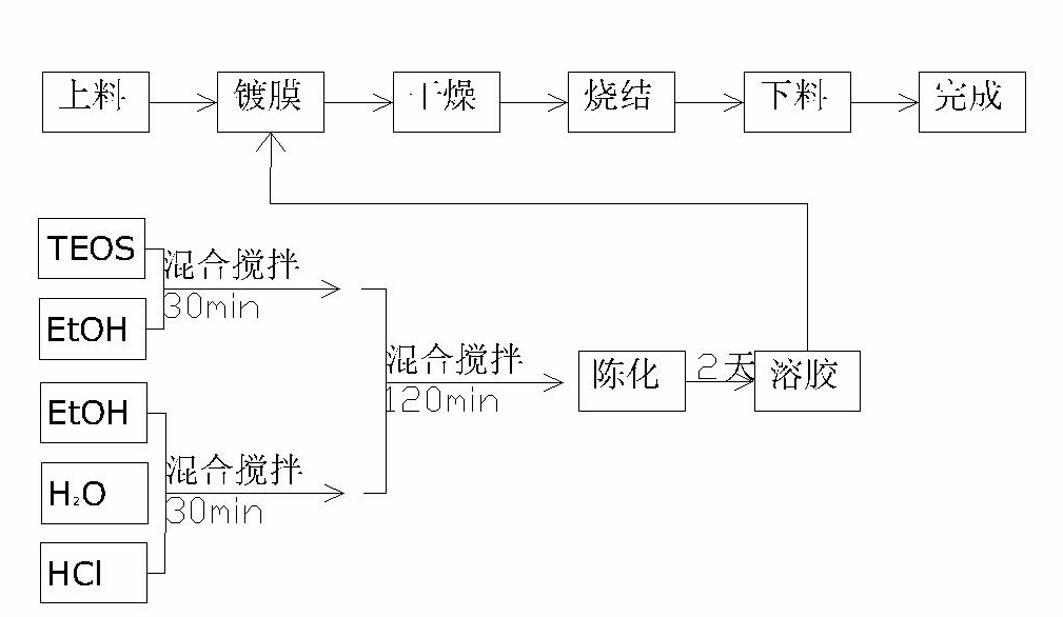

[0091] According to the volume ratio of sol solution TEOS:EtOH:H 2 O: HCl solution = 1: 2: 0.2: 0.02 The preparation of sol C is marked as component 1, and the anti-reflection coating of the glass tube of the high-temperature heat collection tube cover is plated in the above production line. Under the same other process conditions, the coating is carried out according to different pulling speeds, and the solar transmittance index after coating is used to characterize.

[0092] There is no strict requirement for the amount of absolute ethanol (EtOH) used in solutions A and B, which is equivalent to dividing the absolute ethanol into two parts according to the overall dosage, and each part is enough to evenly dissolve the corresponding components to be dissolved.

[0093] See attached table 1 for the results

[0094] Table 1 Effect of pulling speed on component 1

[0095] 1 2 3 Lifting speed 80mm / min 160mm / min 300mm / min AR Solar Transmittance 94....

Embodiment 2

[0098] According to the volume ratio of the sol solution TEOS:EtOH:H2O:HCl solution=1:5:0.2:0.02, the preparation of the sol solution C is marked as component 2, and the anti-reflection coating layer of the high-temperature heat collector tube cover glass tube is coated on this production line . Under the same other process conditions, the coating is carried out according to different pulling speeds, and the solar transmittance index after coating is used to characterize. See attached table 2 for the results

[0099] Table 2 Effect of pulling speed on component 2

[0100] 1 2 3 Lifting speed 80mm / min 160mm / min 300mm / min AR Solar Transmittance 94.6 94.4 94.0 Substrate solar transmittance 90.5 90.5 90.5 increase value 4.1 3.9 3.5

[0101] It can be seen from Table 2 that the coating effect is better when the pulling speed of component 2 is 80 mm / min, and the solar transmittance is increased by 4.1 percentage points relative ...

Embodiment 3

[0104] Preferably, for component 1, adjust the amount of water and acid, TEOS:ETOH:H2O:HCL=1:5:1:0.15 to get component 3. The solar transmittance increase value is basically close. From the perspective of production cost, the life of the sol solution is an important indicator. The service life of the sol is shown in Table 3

[0105] Table 3. Comparison of service life of sol

[0106] components service life component 1 57 days Component 3 103 days

[0107] The preferred component 1 has a longer service life. Because the water content of component 3 is relatively high, it has reached the stoichiometric point of the sol reaction, so the reaction is violent and the life span is short. At the same time, the addition of acid acts as a catalyst for the reaction, and the amount is directly related to the length of life. Therefore, the preferred optimal formula is component 1 TEOS:ETOH:H2O:HCL=1:2:0.2:0.02. This formula has relatively high solar tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com