Ecological preparation method of anti-ultraviolet wool and silk textiles based on orange peel

An orange peel, anti-ultraviolet technology, used in textiles and papermaking, dyeing, fiber processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

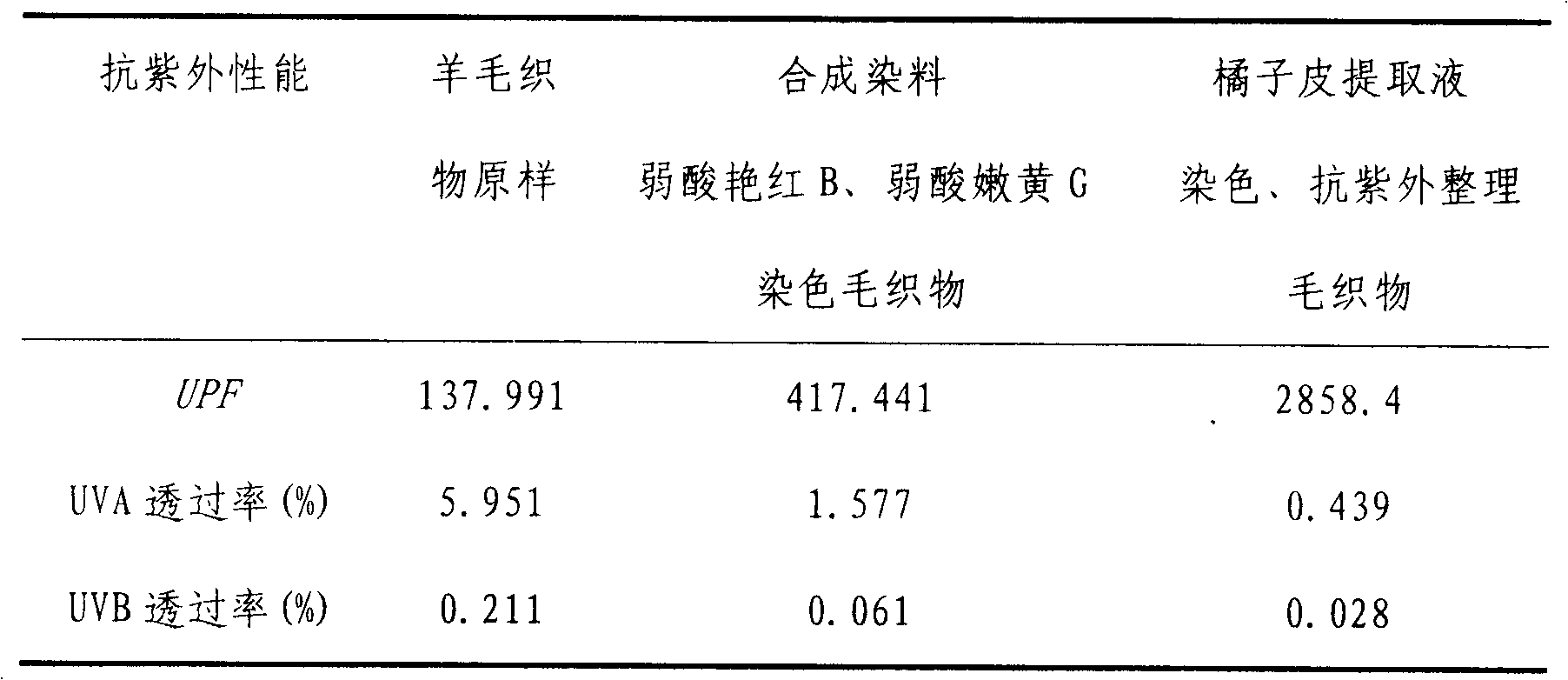

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The first step: natural orange peel extraction

[0024] Cut fresh or dried natural orange peel into thin strips and extract with deionized water. The extraction process is as follows: the solvent mass is 30 times the mass of orange peel, the extraction temperature is 100°C, and the extraction time is 120 minutes;

[0025] The second step: filter the orange peel extract

[0026] Adopt 80 mesh metal screens to carry out coarse filtration to orange peel extract, remove filter residue;

[0027] The third step: orange peel extract centrifugation

[0028] Use a centrifuge to centrifuge the orange peel extract at normal temperature, with a rotating speed of 5000 rpm and a centrifugation time of 15 minutes, and collect the supernatant to obtain a transparent and clear orange peel extract;

[0029] Step 4: Use the orange peel extract to dye wool and silk fabrics in the same bath and finish them with anti-ultraviolet function

[0030] Use orange peel extract to dye wool and si...

Embodiment 2

[0032] The first step: natural orange peel extraction

[0033] Cut fresh or dried natural orange peel into thin strips, extract with a mixed solvent of deionized water and alcohol, the mass percentages of deionized water and alcohol are 25% and 75%, and the quality of the solvent used is 10 times that of the orange peel. Temperature 60°C, extraction time 100min;

[0034] The second step: filter the orange peel extract

[0035] Adopt 100 mesh metal sieves to carry out rough filtration to orange peel extract, remove filter residue;

[0036] The third step: orange peel extract centrifugation

[0037] Use a centrifuge to centrifuge the orange peel extract at room temperature, with a rotating speed of 4000 rpm and a centrifugation time of 15 minutes, and collect the supernatant to obtain a transparent and clear orange peel extract;

[0038] Step 4: Use the orange peel extract to dye wool and silk fabrics in the same bath and finish them with anti-ultraviolet function

[0039] U...

Embodiment 3

[0041] The first step: natural orange peel extraction

[0042]Cut the fresh or dried natural orange peel into thin strips, extract with deionized water and alcohol mixed solvent, the mass percentage of deionized water and alcohol is 20% and 80%, and the quality of the solvent used is 20 times the mass of orange peel, extract The temperature is 70°C, and the extraction time is 60 minutes;

[0043] The second step: filter the orange peel extract

[0044] Adopt 200 mesh metal screens to carry out coarse filtration to orange peel extract, remove filter residue;

[0045] The third step: orange peel extract centrifugation

[0046] Use a centrifuge to centrifuge the orange peel extract at room temperature, with a rotating speed of 3000 rpm and a centrifugation time of 20 minutes, and collect the supernatant to obtain a transparent and clear orange peel extract;

[0047] Step 4: Use the orange peel extract to dye wool and silk fabrics in the same bath and finish them with anti-ultr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com