Method for fully mechanized continuously-filling coal mining of steeply pitching coal seam

A technology of filling coal mining and steep inclination, which is applied in the direction of filling, ground mining, mining equipment, etc. It can solve the problems of high pressure on the surrounding rock of the roadway, and achieve the effects of preventing gas accumulation, reducing pollution, and reducing surface disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

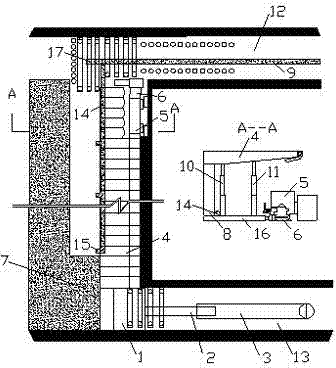

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

[0021] Concrete steps of the present invention are as follows:

[0022] A mine paste filling system is built on the ground, and the filling trunk pipeline 9 is laid from the ground to the upward trough 12; the coal mining machine 5, the scraper conveyor 6, the fully mechanized mining hydraulic support 4 and the air cushion 8 are installed on the working face, and the air cushion 8 is arranged on the fully mechanized mining hydraulic pressure On the base 16 on the gob side of the back column 10 of the support 4, it moves together with the fully mechanized mining hydraulic support 4; The reloading machine 2 and the retractable belt conveyor 3 are installed in the tank 13; every time the mining face is pushed forward by 1.4-1.8m, after the frame is moved, the filling pipeline 14 of the working face is connected with the filling main line pipeline 9 in the upper tank 12 F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com