Energy-saving technology utilizing device of integrated type natural gas compressor

A natural gas and compressor technology, applied in the field of energy-saving technology utilization of integral natural gas compressors, to reduce impact and damage, and improve the energy utilization rate of waste gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

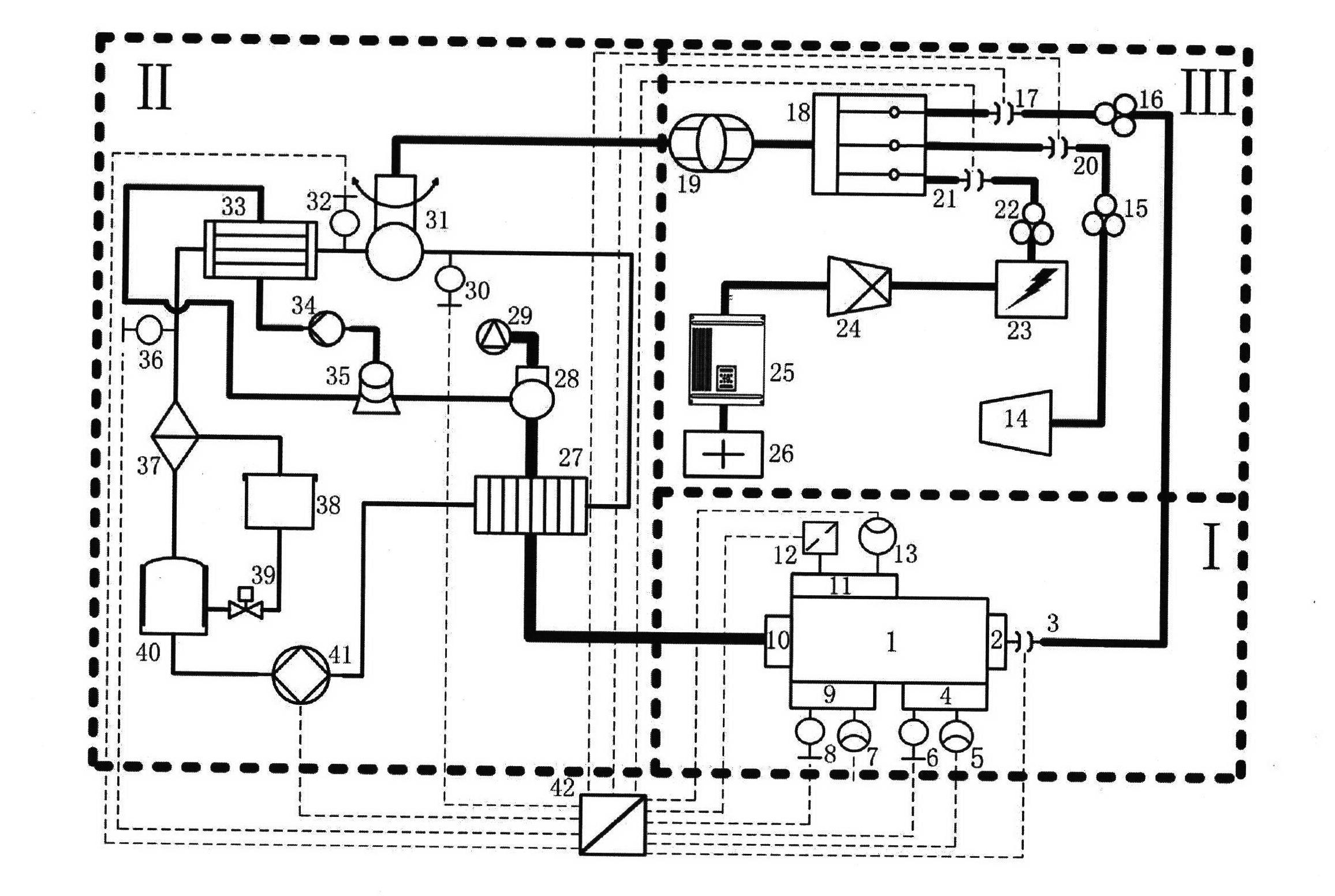

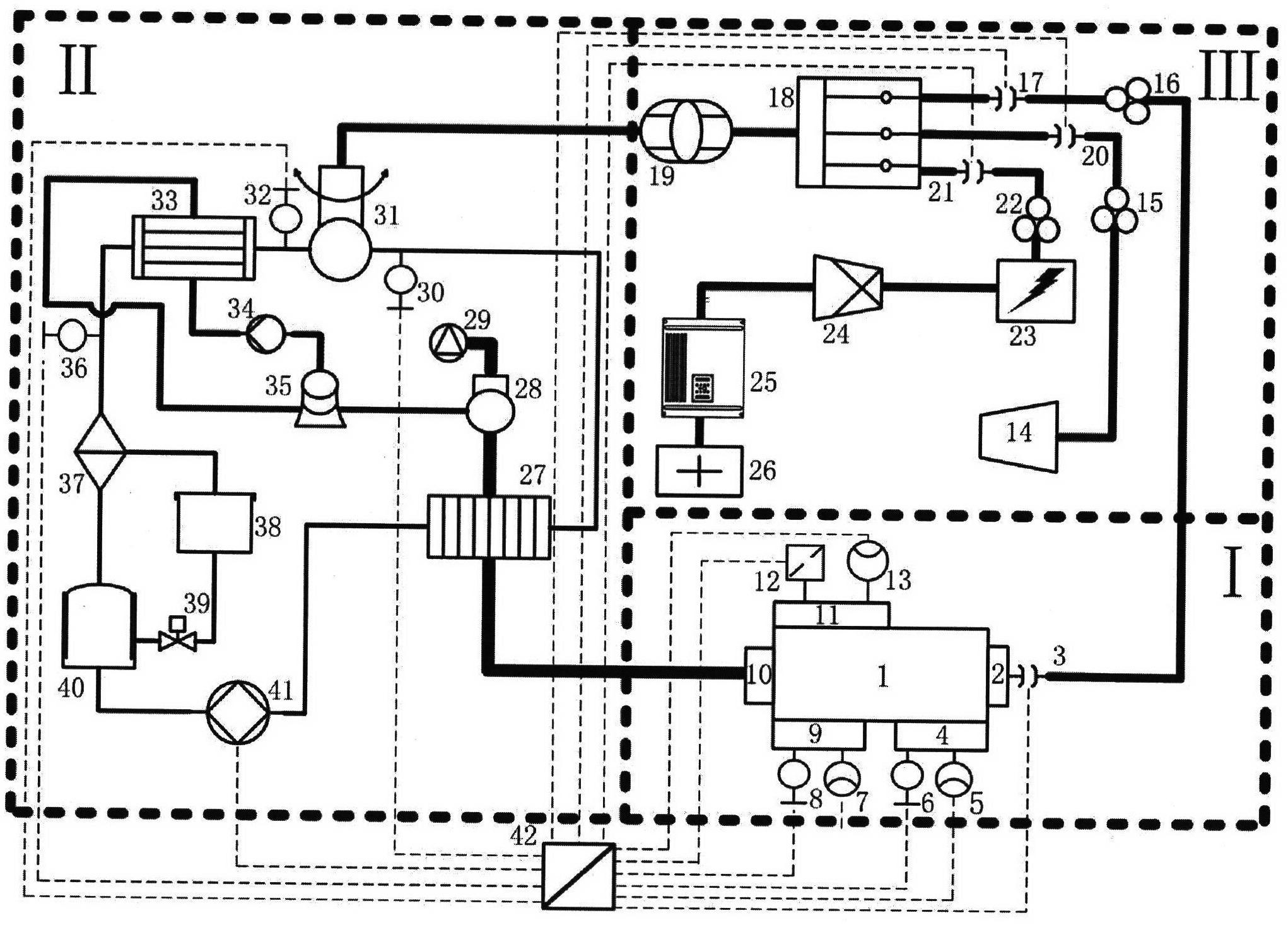

[0013] The following is attached figure 1 The energy-saving technology utilization device of the integral natural gas compressor of the present invention is further elaborated:

[0014] When the integrated natural gas compressor 1 is in operation, the control unit 42 collects the mass flowmeter I5 and the temperature and pressure sensor I6 on the low-pressure intake main pipe 4 and the mass flowmeter II7 and temperature and pressure sensor II8 on the high-pressure gas outlet main pipe 9 respectively. signal, calculate the load requirement, and build an adaptive gas supply model. According to the constructed adaptive gas supply model, the controller 42 collects the signal of the temperature and pressure sensor III13 on the gas supply pipe 11, and transmits the signal in real time through the electronically controlled proportional valve 12. The power gas supply is adjusted to reduce the natural gas supply required for the integral natural gas compressor 1 on the premise of meeti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com