Wind tunnel model ice shape measuring method and device

A measuring method and technology for measuring devices, which are applied to measuring devices, using optical devices, instruments, etc., can solve the problems of inability to accurately measure ice-shaped contour shape data, large random errors in measurement, and high labor intensity, and achieve a low contour blind spot rate. , The effect of small random error in measurement and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

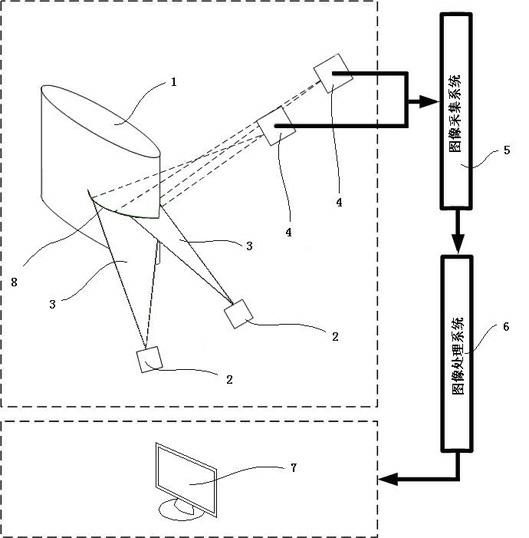

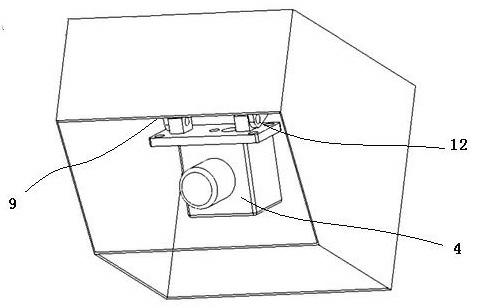

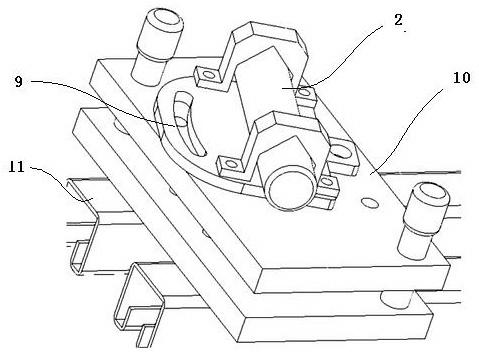

[0034] The optical measurement method is currently the most widely used in three-dimensional geometric shape measurement, and it is also the fastest non-contact method to accurately obtain the contour size of the relative measurement speed. This method can be used for point-by-point, line-by-line scanning measurements, or full-field measurements, all of which depend on the shape of the optical signal projected on the object being sided, such as light spots, rays or gratings. In the measurement of the outline dimension of the icing body, it is required to quickly reflect the section characteristics of the icing body under test, so the optical section method based on laser sheet light and machine vision is selected. The measurement speed of this method is faster than that of the point scanning method, and the measurement accuracy is higher than that of the projected grating or binocular measurement method. The shape and outline of the blind zone rate is low.

[0035] To calibra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com