Force measuring apparatus of jet vane carried engine hot firing test

A force measuring device and gas rudder technology, applied in the direction of gas turbine engine testing, jet engine testing, measuring devices, etc., can solve problems such as poor versatility, difficulty in realizing complex test conditions and accurate simulation, and low measurement accuracy, and achieve accurate deflection , reliable heat protection device, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

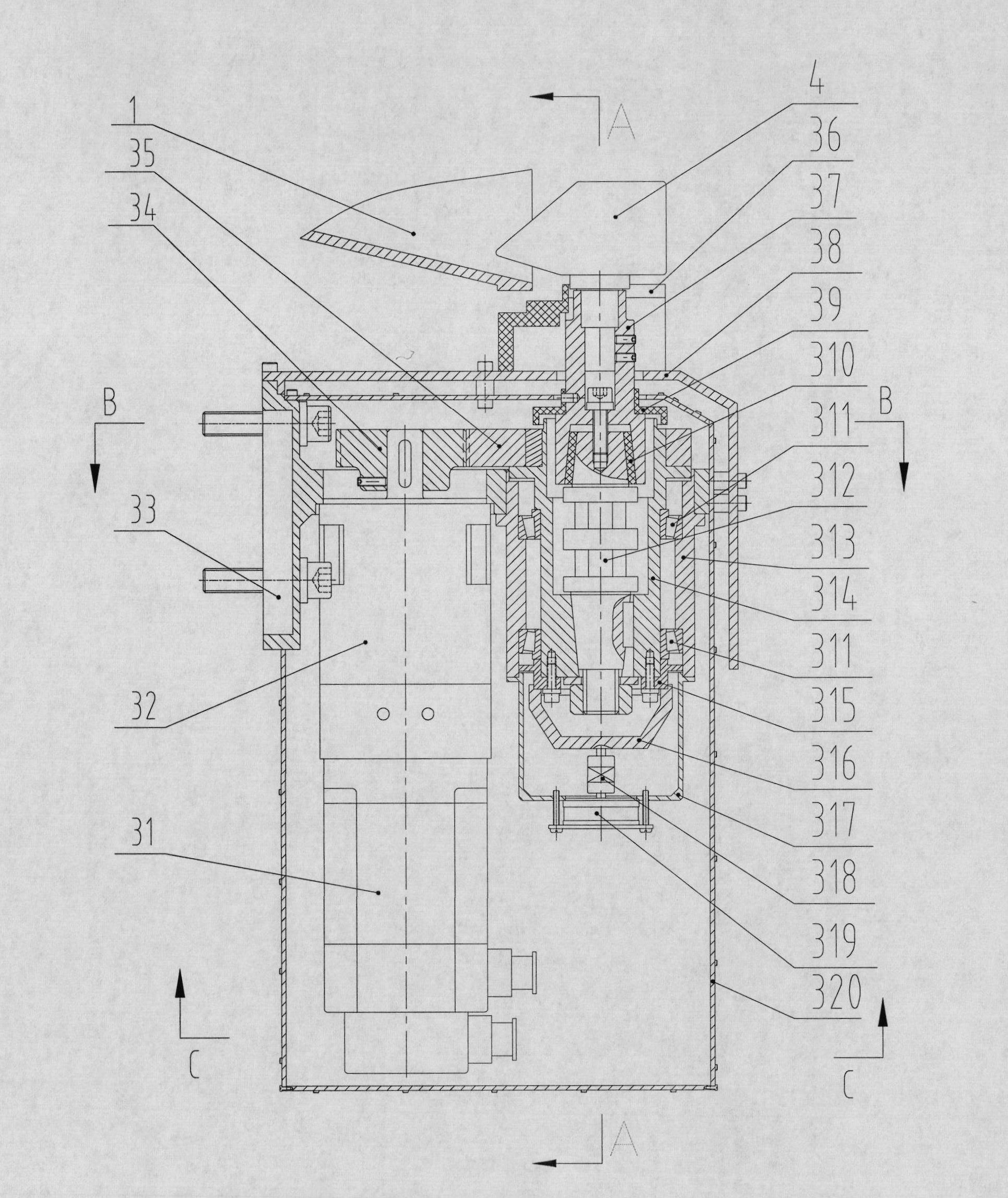

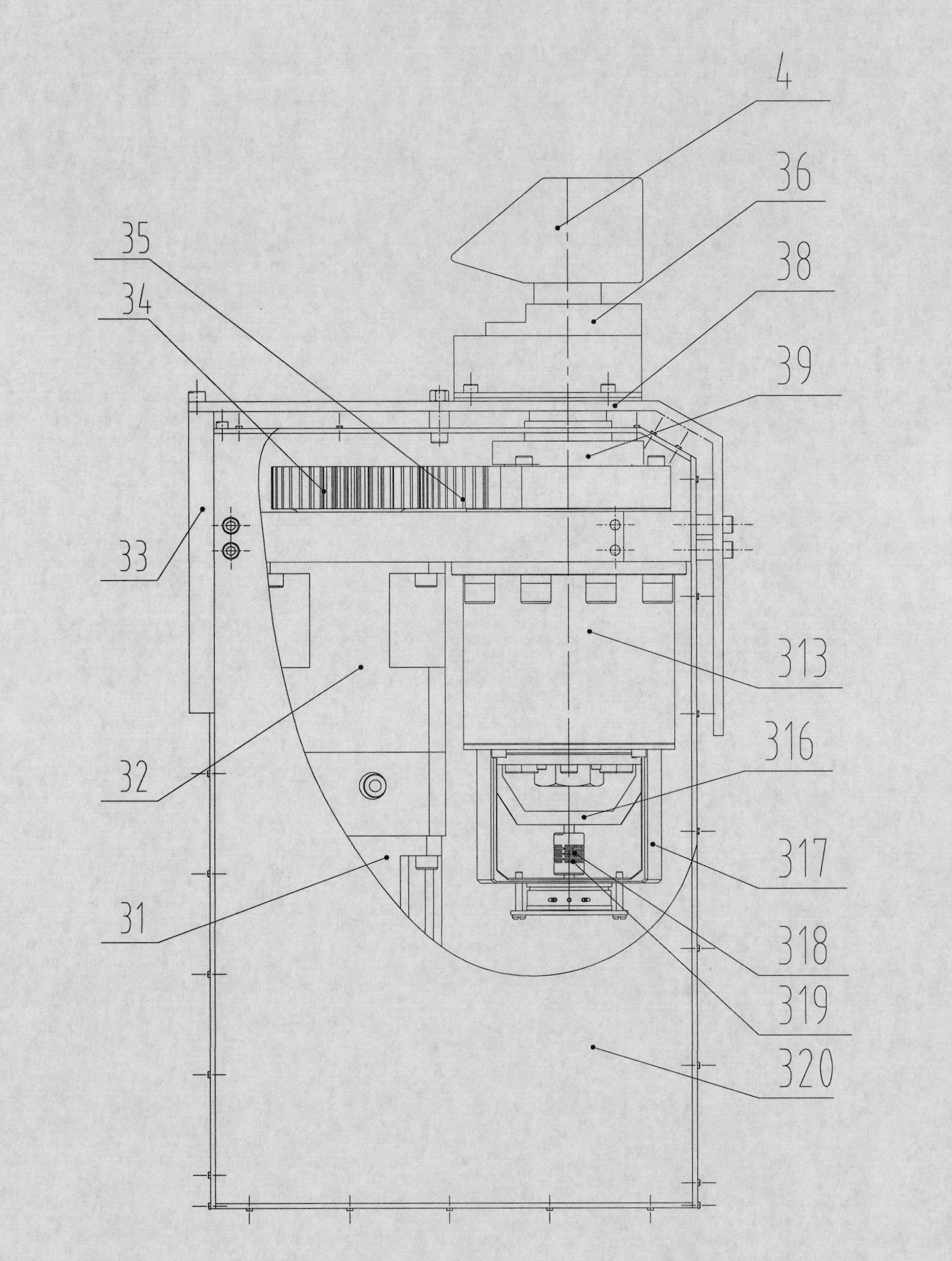

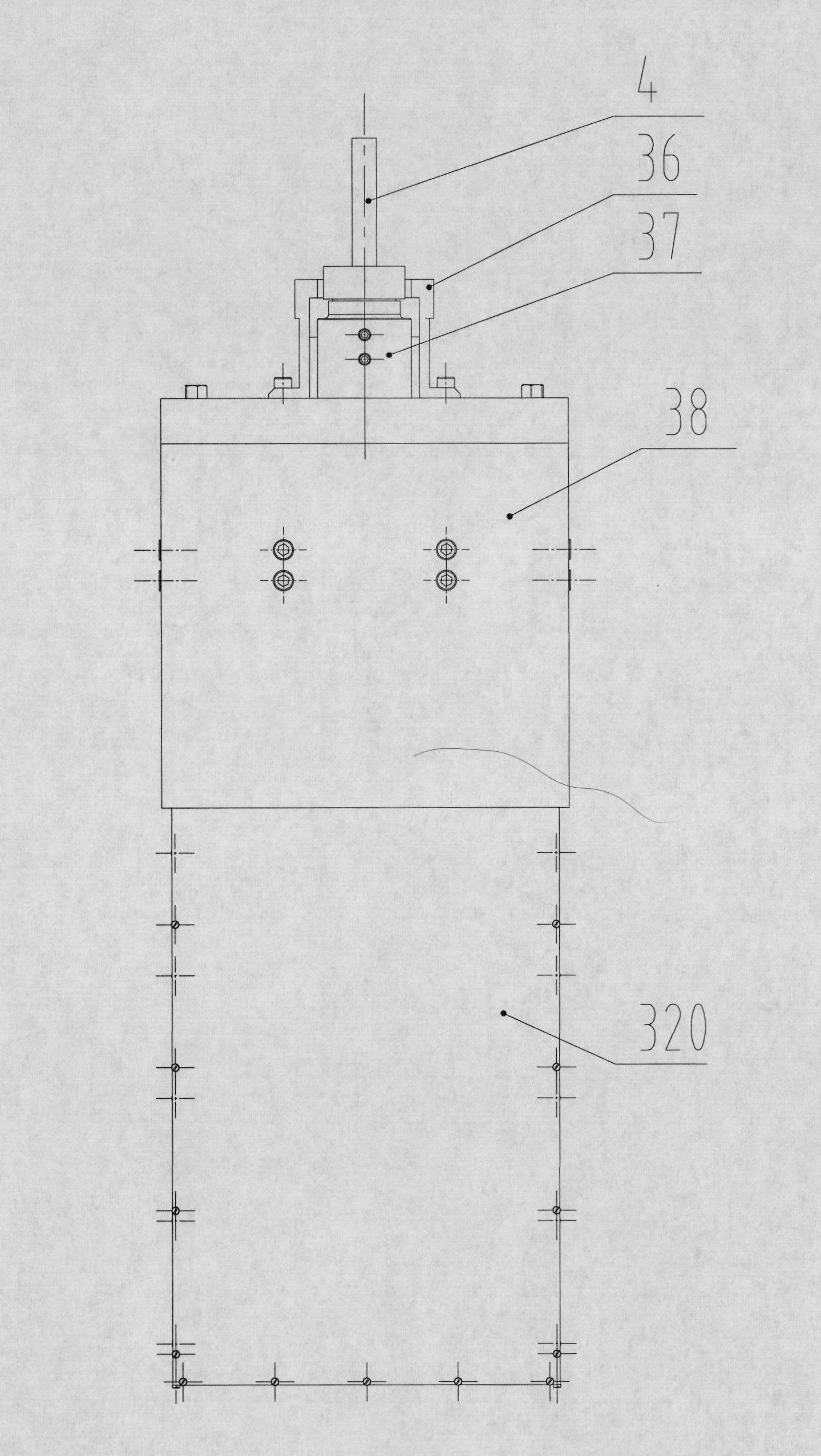

[0046] The invention relates to a force measuring device for a thermal test run of an engine equipped with a gas rudder. The force measuring device can be directly installed on the end frame of the tail skirt of the engine through an external fixing mechanism, or can be installed on an independent fixing mechanism fixed on the ground. The relative position between the fixing mechanism and the test bench of the fixed engine realizes the relative positioning of the gas rudder and the engine tail nozzle; a set of force measuring device can drive a piece of gas rudder deflection, and measure its real deflection angle and corresponding aerodynamic load. During the test, the driving mechanism composed of a motor and a reducer in the force measuring device drives the gas rudder to deflect quickly and accurately in the jet flow of the engine. (Total resistance tolerance is less than 0.01%.) The angle sensor is composed of real-time and accurate measurement of the real deflection angle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com