Sample gas processing detection system and method for on-line analysis meter

A detection system and analysis instrument technology, applied in sampling devices, preparation of test samples, etc., can solve the problem of large measurement error of oxygen analyzer, and achieve the effect of high cleanliness, accuracy and stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

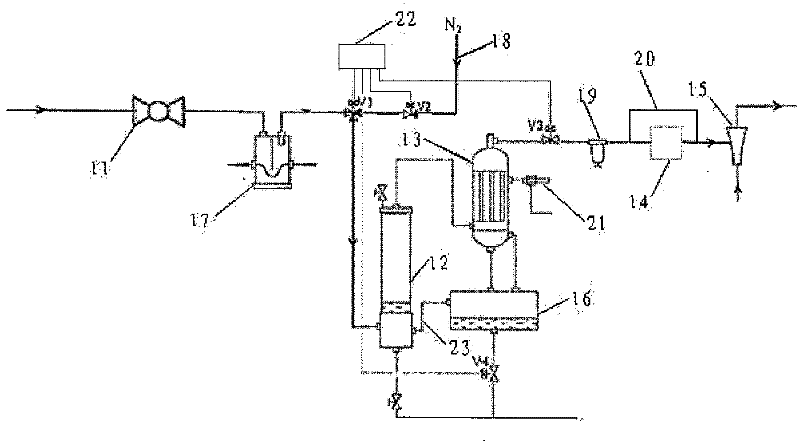

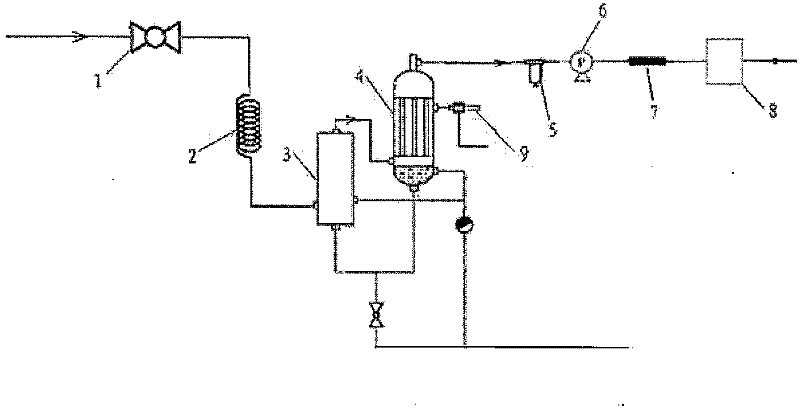

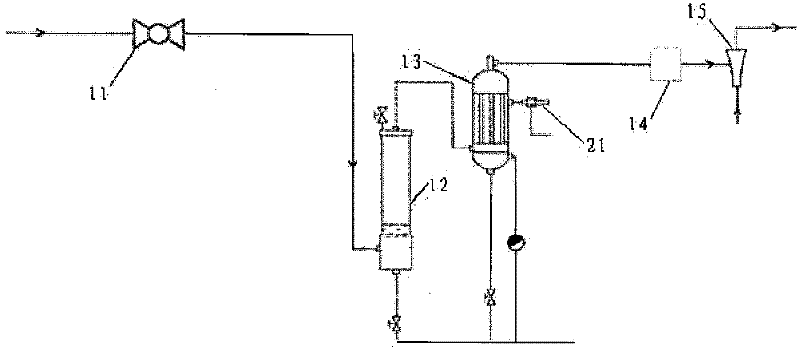

Image

Examples

Embodiment 1

[0064] Regularly use standard gas to calibrate the zero point and span of the oxygen analyzer. The specific experimental data are shown in Table 1.

[0065] Table 1 The results of zero point and span calibration of the instrument after system improvement using standard gas

[0066]

[0067] The instrument is calibrated at zero point and span every other week. Four groups of experiments have been accumulated to show that the data analyzed by the instrument has high accuracy and meets the performance index of zero point drift and span drift less than 0.05% / week, and there is no need to adjust zero point and span. From the analysis of the principle of the instrument, the dust attached to the measuring medium attached to the sensor is one of the main reasons for the drift of the zero point and range of the meter. technical indicators.

Embodiment 2

[0074] In order to verify the application effect of the oxygen analyzer in the actual analysis of the sample gas of the pulverized coal system after the system transformation, the sample gas was analyzed on-line by instrument and manually every other week for a period of time. The specific data are shown in Table 3.

[0075] Table 3 Comparison data of manual analysis and instrument analysis of sample gas after system improvement

[0076]

[0077]

[0078] It can be seen from Table 2 that the numerical consistency between the actual on-line analysis of the instrument and the manual analysis is relatively good (the manual analysis data retains 3 significant figures, and the actual measurement analysis of the instrument retains 2 significant figures), indicating that the analysis results of the instrument after the system improvement meet the error Less than 0.5 is required.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com