Semiconductor material measuring device and method for in-situ measurement of interface defect distribution

A technology for measuring device and interface defect, applied in the direction of measuring device, material analysis using wave/particle radiation, analyzing materials, etc., to achieve the effect of improving work efficiency and avoiding pollution and oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

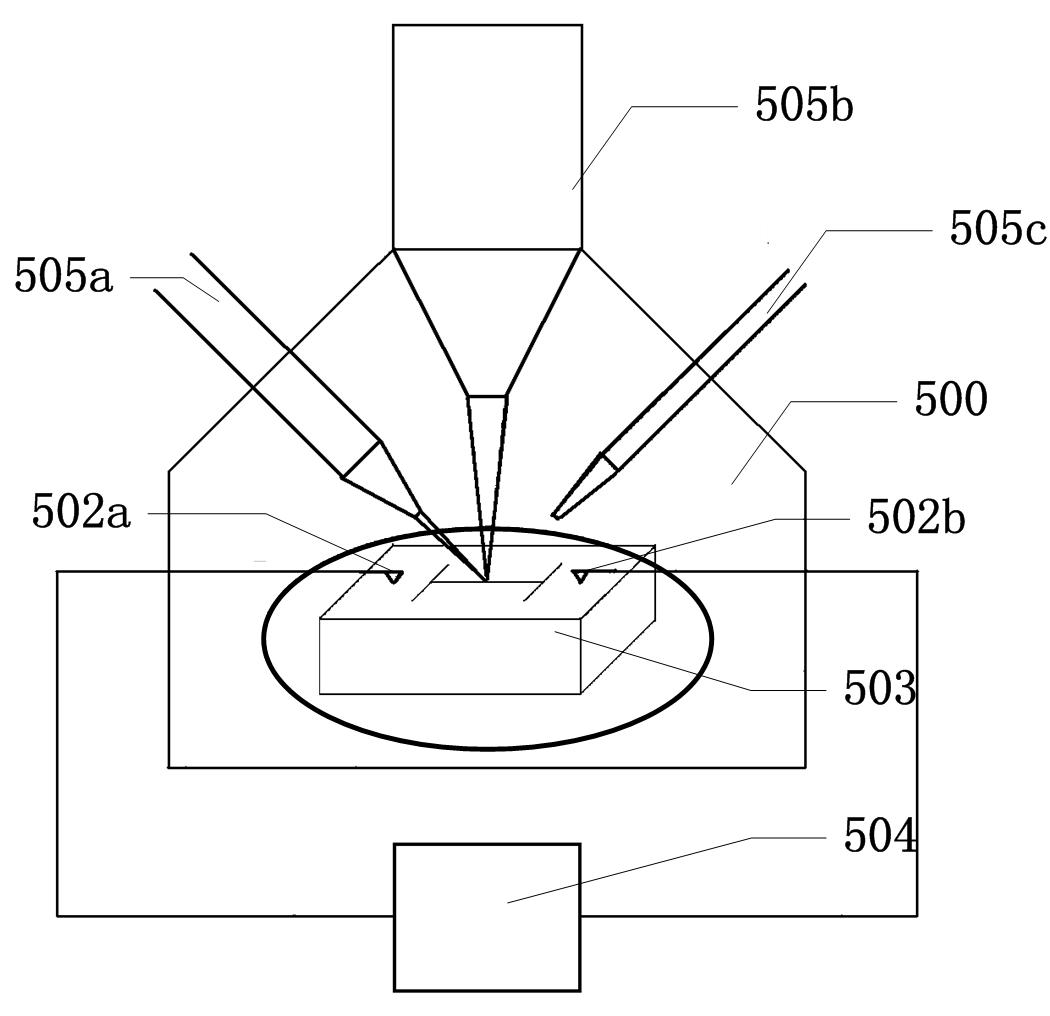

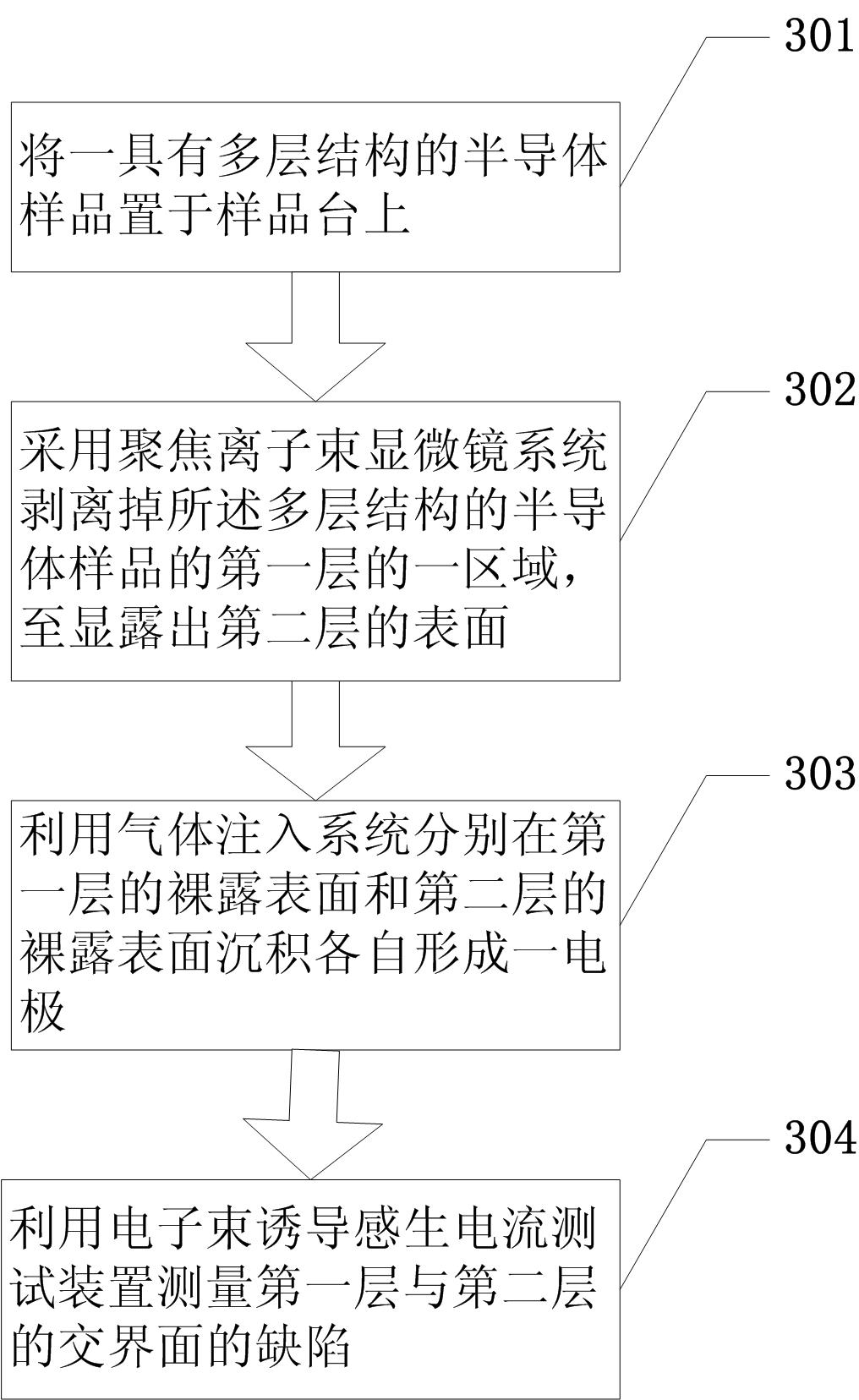

[0024] figure 2 Shown is a flowchart of a second embodiment of the method for in-situ measurement of interface defect distribution provided by the present invention, including:

[0025] Step 301, placing a semiconductor sample with a multilayer structure on the sample stage;

[0026] Step 302, using a focused ion beam microscope system to peel off a region of the first layer of the semiconductor sample with a multilayer structure until the surface of the second layer is exposed;

[0027] Step 303, using a gas injection system to respectively deposit an electrode on the exposed surface of the first layer and the exposed surface of the second layer;

[0028] Step 304, measuring the defects of the interface between the first layer and the second layer by using an electron beam induced induced current measuring device.

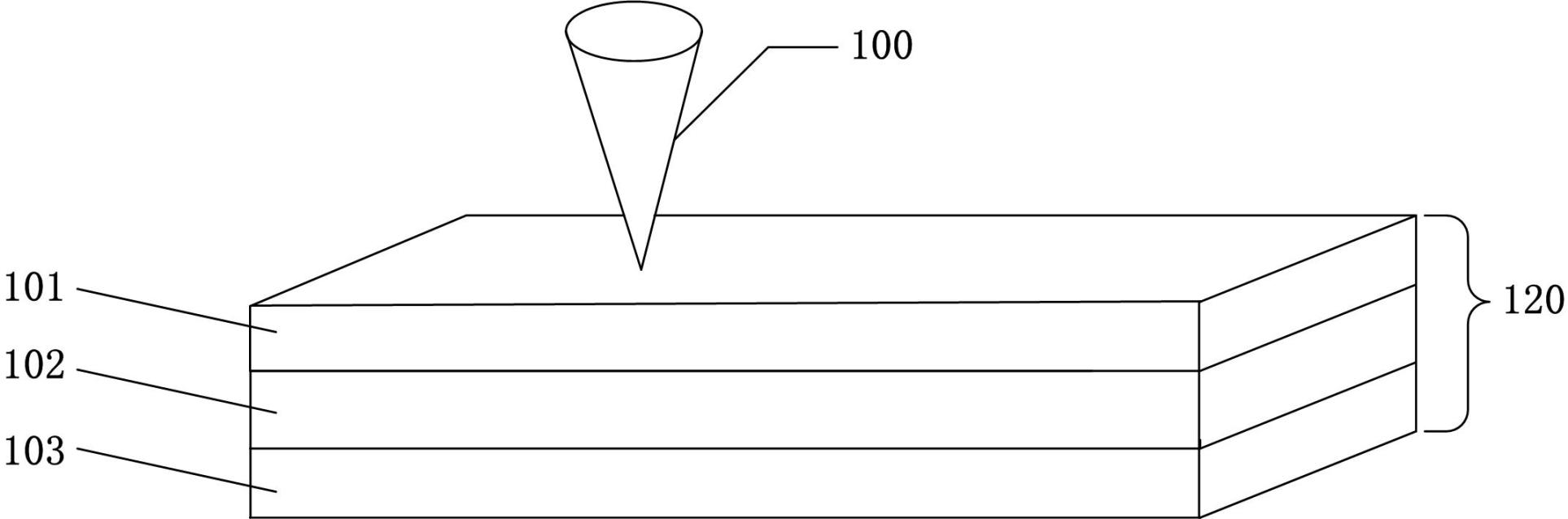

[0029] image 3 Shown is a schematic diagram of step 301 according to the second embodiment of the present invention. A semiconductor sample 120 with a multilayer structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com