Sensor-less control device and control method of sectional-winding linear motor

A segmented linear control device technology, applied in the direction of motor generator control, AC motor control, electromechanical transmission control, etc., can solve the problem that the sensorless control of ordinary high-speed motors cannot be controlled by winding segmented linear motors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

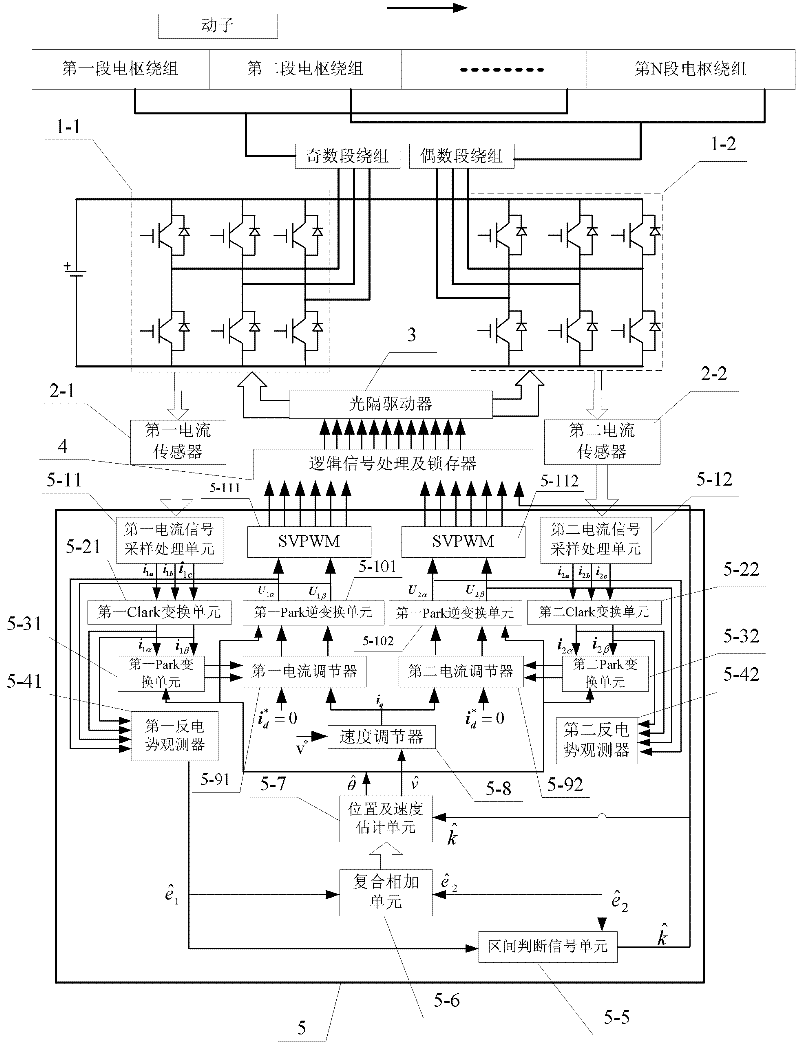

[0080] Specific implementation mode one: the following combination Figure 1 to Figure 6 Describe this embodiment, the sensorless control device of the winding segmented linear motor in this embodiment, the length of each stator segment of the linear motor is greater than the length of the linear motor mover along the moving direction, and it is characterized in that: The first intelligent power module 1-1, the second intelligent power module 1-2, the first current sensor 2-1, the second current sensor 2-2, the optical isolation driver 3, the logic signal processing and latch 4 and the micro The controller consists of DSP5,

[0081] The microcontroller DSP5 is composed of the first current signal sampling processing unit 5-11, the second current signal sampling processing unit 5-12, the first Clark transformation unit 5-21, the second Clark transformation unit 5-22, the first Park transformation unit 5-31, the second Park transformation unit 5-32, the first back EMF observer ...

specific Embodiment approach 2

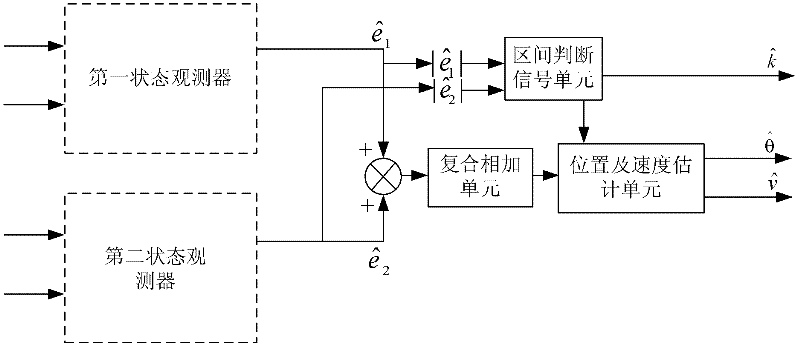

[0093] Specific implementation mode two: the following combination figure 2 This embodiment is described. This embodiment is a further description of Embodiment 1. The first back EMF observer 5-41 and the second back EMF observer 5-42 in this embodiment are state observers.

specific Embodiment approach 3

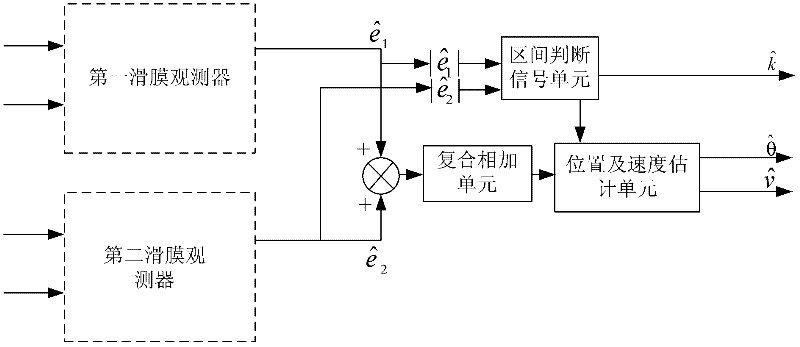

[0094] Specific implementation mode three: the following combination image 3 This embodiment is described. This embodiment is a further description of Embodiment 1. The first back EMF observer 5-41 and the second back EMF observer 5-42 in this embodiment are synovium observers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com