Fiber spreading printing system

A printing system and fiber technology, applied in printing, printing machine, printing process, etc., can solve the problems of high cost, difficult to adapt, long order cycle, etc., to avoid serious local bulges, prevent easy rubbing, and avoid shrinkage uneven roll effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

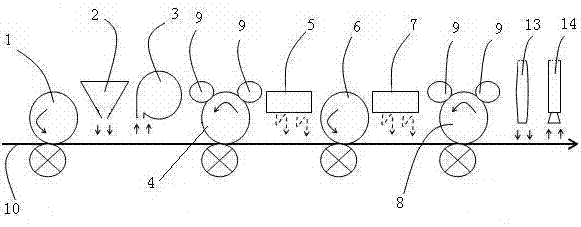

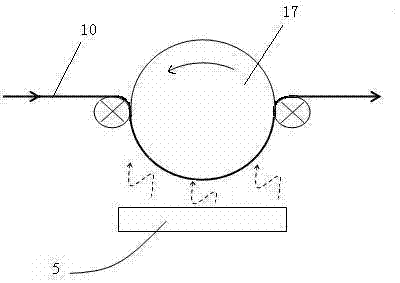

[0029] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, design and manufacture a fiber-spreading gravure printing (machine) system.

[0030] According to the technical standard of the current gravure printing machine, make a discharge unit (not shown) with a deviation correction system (not shown in the figure), an automatic tension system (not shown in the figure), and a static elimination system (not shown in the figure) and a receiving unit (not shown in the figure), so that the continuous printing material (10) is sent from the discharging unit to the receiving unit for collection.

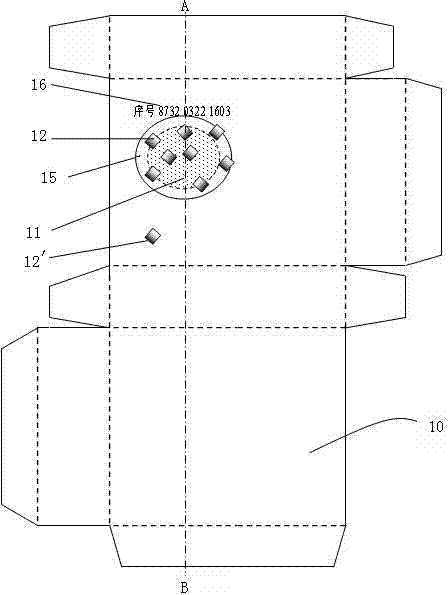

[0031]Then install the gravure glue printing unit (1), which is arranged between the discharging unit and the receiving unit, and is used to print the glue layer (11) on the printing material (10), and UV bonding can be selected agent glue; the glue layer (11) can be printed into geometric figures of any shape; the glue layer (11) is used to bond the fibers (12). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com