Cord winding and partitioning machine

A technology of dividing machine and wire rope, which is applied in the directions of sending objects, thin material processing, transportation and packaging, etc., can solve the problems of high labor intensity of workers, dimensional errors of rubber belts, uneven pre-segmentation, etc., to reduce labor intensity and precision. High, easy-to-control cutting depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

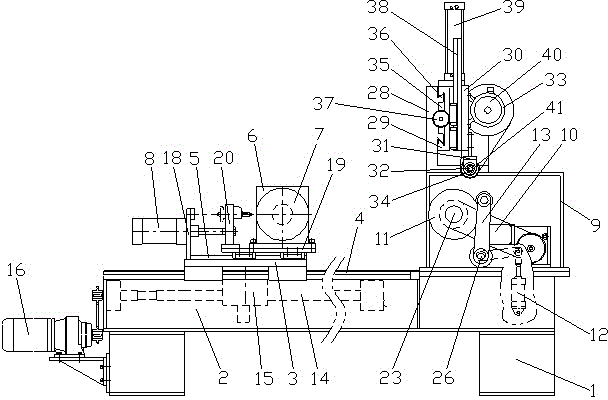

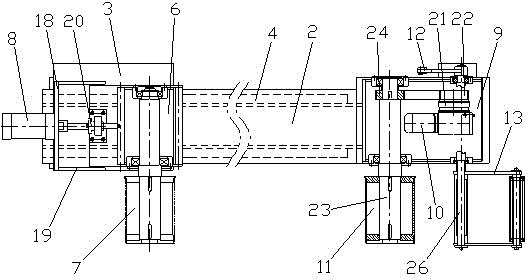

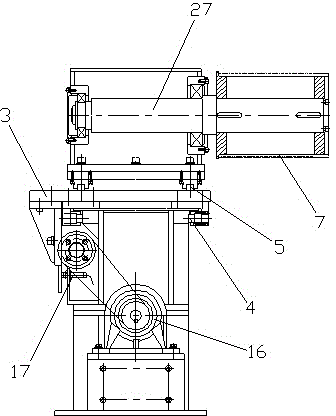

[0022] The present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

[0023] refer to Figure 1~7 , a wire rope winding and dividing machine, comprising a machine base 2 supported by a machine base base 1, the front and rear sides of the machine base 2 are provided with first slide rails 4 matched with the carriage 3, the machine base 2 is provided with a screw nut auxiliary mechanism for driving the carriage 3 to move left and right on the first slide rail 4; the upper side of the carriage 3 is provided with a second slide rail 5 and a Driven wheel base 6, grooved roller 7 is installed on described driven wheel base 6, and described grooved roller 7 is installed on the driven shaft 27 of grooved roller, and described carriage 3 is provided with for driving driven wheel base 6 on the second slide A telescopic cylinder 8 that moves left and right on the rail 5; the right end of the base 2 is provided with a spindle box 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com