Preparation method for gas permeable brick with straight through type gas channels

A breathable brick and straight-through technology, which is applied in the field of refractory materials, can solve the problems of increased production cost of breathable bricks, poor refining effect, small airway size, etc., achieve excellent thermal shock resistance, improve blowing rate, and airway performance Optimized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

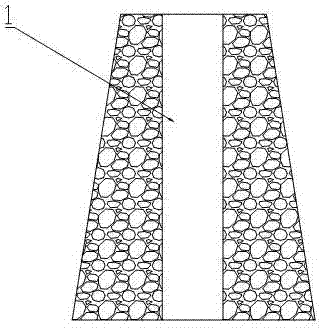

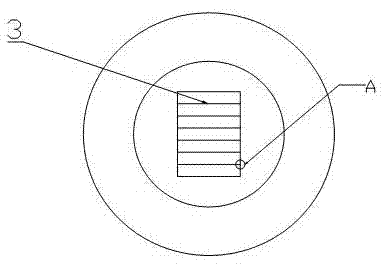

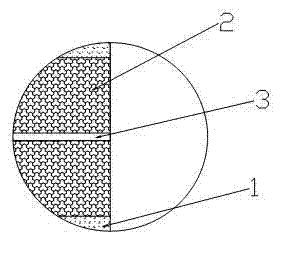

[0027] Embodiment 2: as Figure 4 , Figure 5 , Figure 6 As shown, another method for preparing a straight-through airway permeable brick requires 30 straight-through airways, and the size of the airway 3 is 300mm×15mm×0.2mm; the prepared slurry is prepared by The material is evenly spread on the plastic lost material. The size of the plastic lost material is 400mm×15mm×0.2mm. The height of slurry application is 310mm and the thickness is 1mm. It has a certain strength and is closely attached to the plastic burnt objects; 30 coated plastic burnt objects are fixed in the mold, poured with castables, and made into bricks. After firing at 1000°C, 30 coated plastic burnt objects Lost objects create 30 straight-through airways in the adobe.

Embodiment 3

[0028] Example 3, a straight-through air brick with 36 straight-through air passages made by a process similar to that of embodiment 2, and the size of the air passages is 350mm×17mm×0.25mm.

[0029] The use of high-grade refractory materials with good performance to produce straight-through airway permeable bricks is the method adopted by many enterprises now; the high-grade refractory materials and molten steel have a large wetting angle, which can effectively prevent the steel from seeping through the airway, improve the blowing rate, and at the same time It also has good high-temperature performance; however, the use of high-grade refractory raw materials increases the production cost of the breathable brick; the present invention treats the air passage part of the breathable brick separately, and has a large wetting angle for molten steel, and the molten steel is not easy to penetrate, and at the same time has good high-temperature performance. The refractory raw material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com