Pouring material for dip pipe of RH refining furnace

A castable and refining furnace technology, which is applied in the field of castables for dipping pipes of RH refining furnaces, can solve the problem of poor corrosion resistance, slag penetration resistance and thermal shock resistance, poor thermal shock resistance of castables, and prone to crack structures, etc. To solve the problem of serious slag hanging on refractory materials, to solve the problem of poor thermal shock resistance and good oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

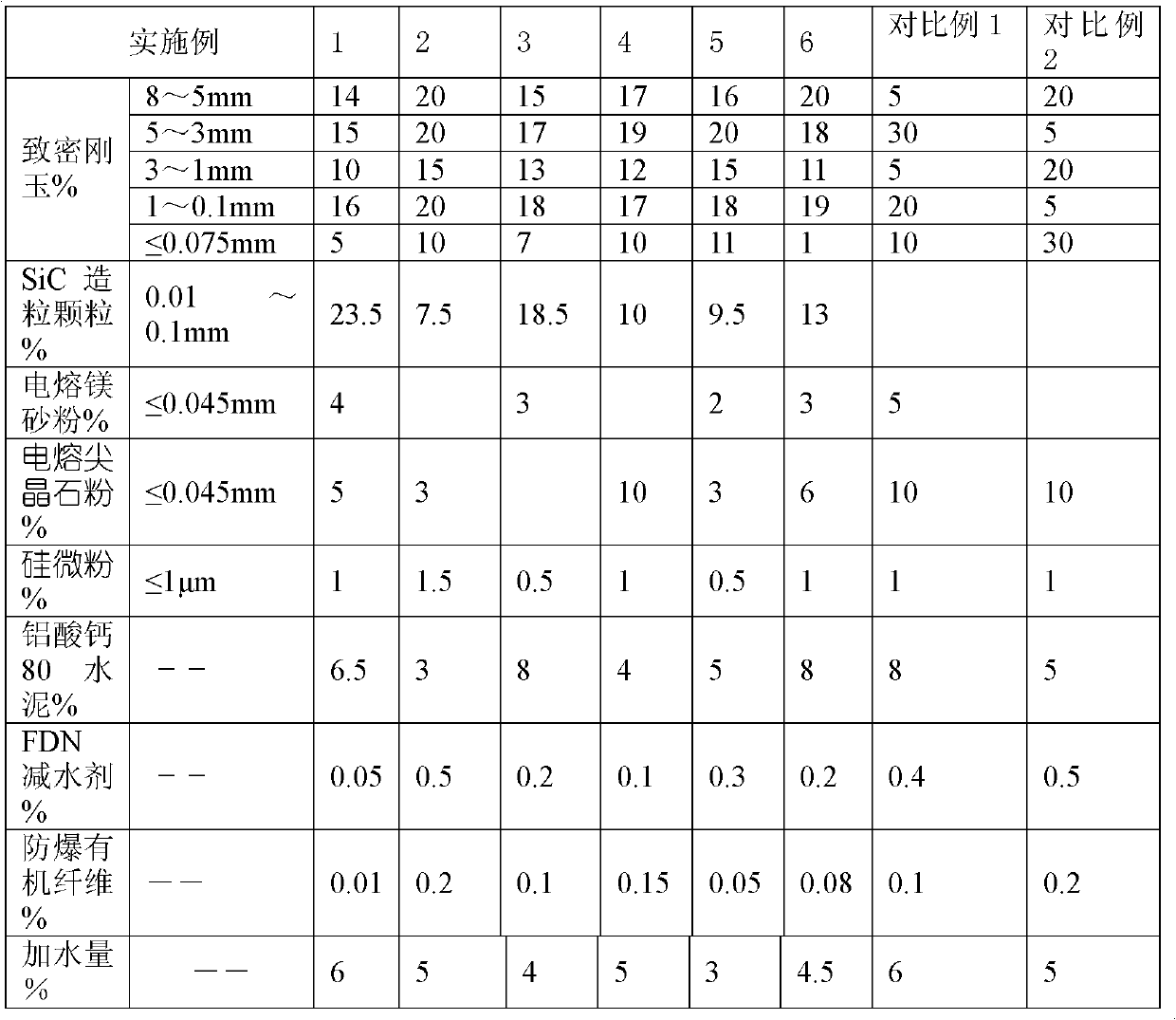

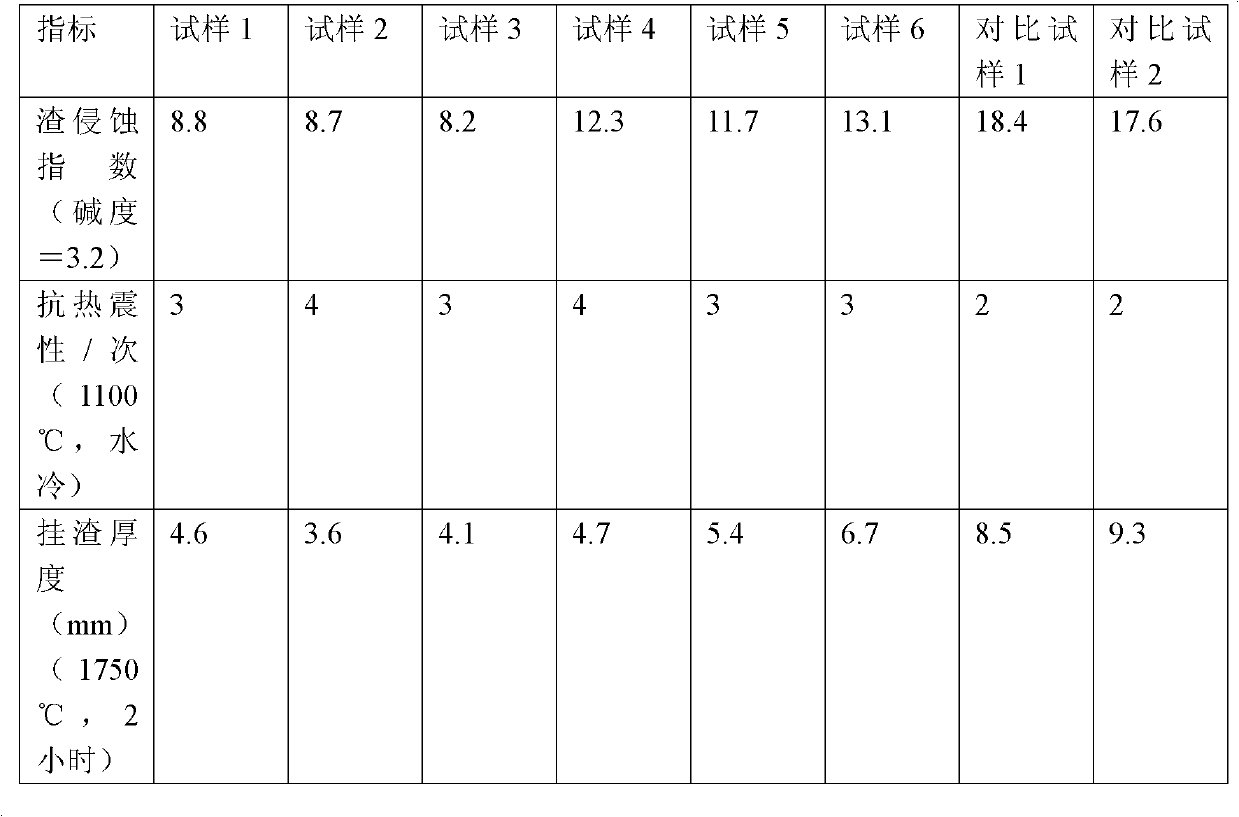

[0020] Table 1 raw material composition and proportioning (percentage by weight):

[0021]

[0022] Preparation method embodiment 1:

[0023] Preparation of SiC granulated particles: Mix SiC particles with a particle size of 0.05-0.005 mm and antioxidant (α-alumina) micropowder with a particle size of 1 / 5 of the SiC particle size at a weight ratio of 1:0.4, and then add the total amount of the mixed material Measure 5% adhesive, mix again, keep the mixture at 220°C for 20 hours, and then crush it into SiC granules with a particle size of 0.01-0.1mm.

[0024] Mix the aggregate and matrix material, and then add FDN water reducer and explosion-proof organic fiber (polypropylene fiber: polyethylene fiber 1:1) and mix to make castable (1).

[0025] Preparation method embodiment 2:

[0026] Preparation of SiC granulated particles: 0.05-0.005mm SiC particles and antioxidant (zirconia) powder with a particle size of 1 / 10 of the SiC particle size are mixed in a weight ratio of 1:0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com