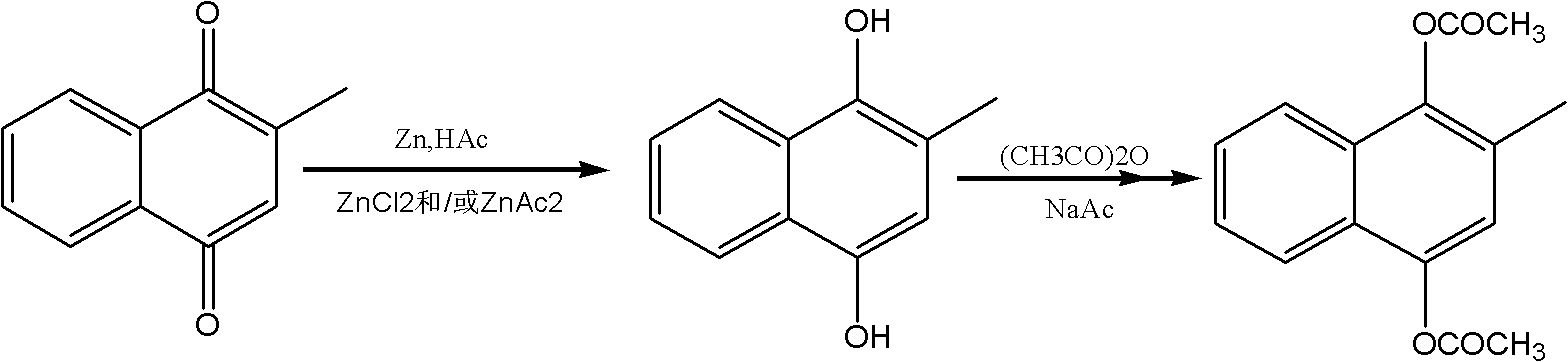

Method for synthesizing menadiol acetate

A technology of menadione hydroquinone acetate and naphthoquinone is applied in chemical instruments and methods, preparation of organic compounds, preparation of carboxylic acid esters, etc., and can solve the problems of incomplete reduction reaction, strong reaction, unsafe placement, etc. The effect of unsafe placement, mild reaction conditions and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Put 90 parts by weight of glacial acetic acid into the reaction kettle, slowly add 53 parts by weight of dry 2-methyl-1,4-naphthoquinone under stirring, stir to form a paste, add 20.5 parts by weight of zinc powder at a controlled temperature of 35°C, Then add the anhydrous zinc chloride of 8 weight parts again, continue stirring reaction 40min after adding;

[0029] Slowly add 140 parts by weight of acetic anhydride under stirring, then add 28 parts by weight of NaAc in 4 times, heat up to 138 ° C, boil and reflux for 3 hours, leave to cool to room temperature, filter off zinc chloride and NaAc, the resulting liquid is continuously Pour it into a large amount of ice water under stirring, let it stand for 1 hour, filter, wash with water until it is acid-free, and dry to obtain the crude menadione acetate.

[0030] Dissolve the crude product in about 5 times of hot ethanol solution (ethanol: water = 9: 1), add 1%-2% activated carbon and stir for 30 minutes to filter whil...

Embodiment 2

[0032] Put 100 parts by weight of glacial acetic acid into the reactor, slowly add 62 parts by weight of dry 2-methyl-1,4-naphthoquinone under stirring, stir to form a paste, add 25.9 parts by weight of zinc powder at a controlled temperature of 35°C, Then add the anhydrous zinc chloride of 12 weight parts again, continue stirring reaction 40min after adding;

[0033] Slowly add 160 parts by weight of acetic anhydride under stirring, then add 30 parts by weight of NaAc in 8 times, heat up to 138°C, boil and reflux for 3h, leave to cool to room temperature, filter off zinc chloride and NaAc, and the resulting liquid is continuously Pour it into a large amount of ice water under stirring, let it stand for 1 hour, filter, wash with water until it is acid-free, and dry to obtain the crude menadione acetate.

[0034] Dissolve the crude product in about 5 times of hot ethanol solution (ethanol: water = 9: 1), add 1%-2% activated carbon and stir for 30 minutes to filter while hot, fr...

Embodiment 3

[0036] Put 95 parts by weight of glacial acetic acid into the reaction kettle, slowly add 58 parts by weight of dry 2-methyl-1,4-naphthoquinone under stirring, stir to form a paste, add 23.2 parts by weight of zinc powder at a controlled temperature of 35°C, Then add the anhydrous zinc chloride of 10 weight parts again, continue stirring reaction 40min after adding;

[0037] Slowly add 150 parts by weight of acetic anhydride under stirring, then add 29 parts by weight of NaAc in 6 times, heat up to 138°C, boil and reflux for 3h, leave to cool to room temperature, filter off zinc chloride and NaAc, and the resulting liquid is continuously Pour it into a large amount of ice water under stirring, let it stand for 1 hour, filter, wash with water until it is acid-free, and dry to obtain the crude menadione acetate.

[0038] Dissolve the crude product in about 5 times of hot ethanol solution (ethanol: water = 9: 1), add 1%-2% activated carbon and stir for 30 minutes to filter while ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com