Coal supporting device of coal gas generation furnace

A gas generator and cover device technology, which is applied in the field of coal bearing devices, can solve problems such as threats to the health of operators, incomplete fuel combustion, waste of raw materials, etc., to avoid energy loss, prevent gas leakage, and reduce environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with specific drawings and embodiments.

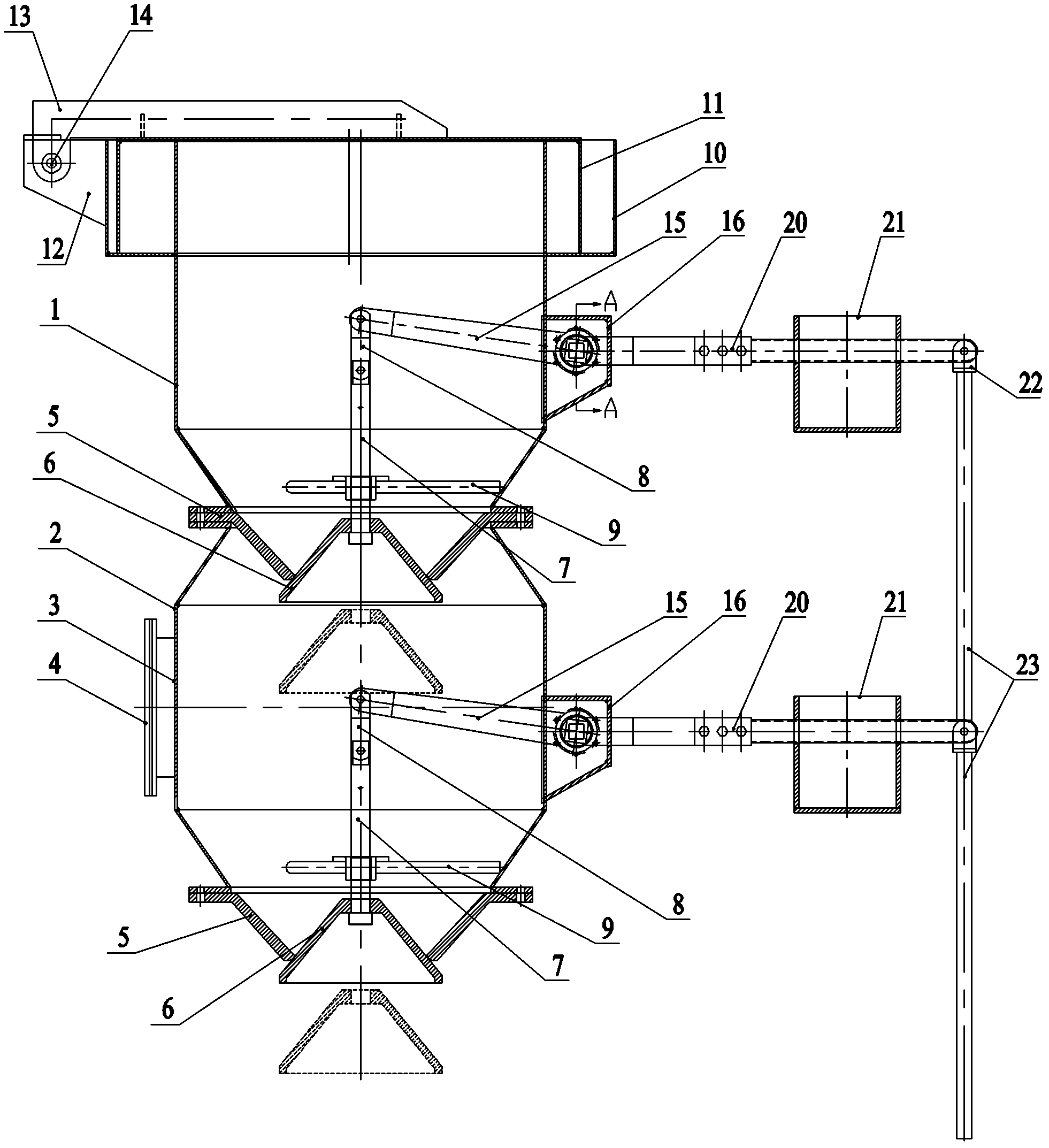

[0024] As shown in the figure, the coal-holding device of the gasifier in the embodiment is mainly composed of an upper coal hopper 1, a lower coal hopper 2, a cover device, a material cup 6 and a material cup lifting mechanism.

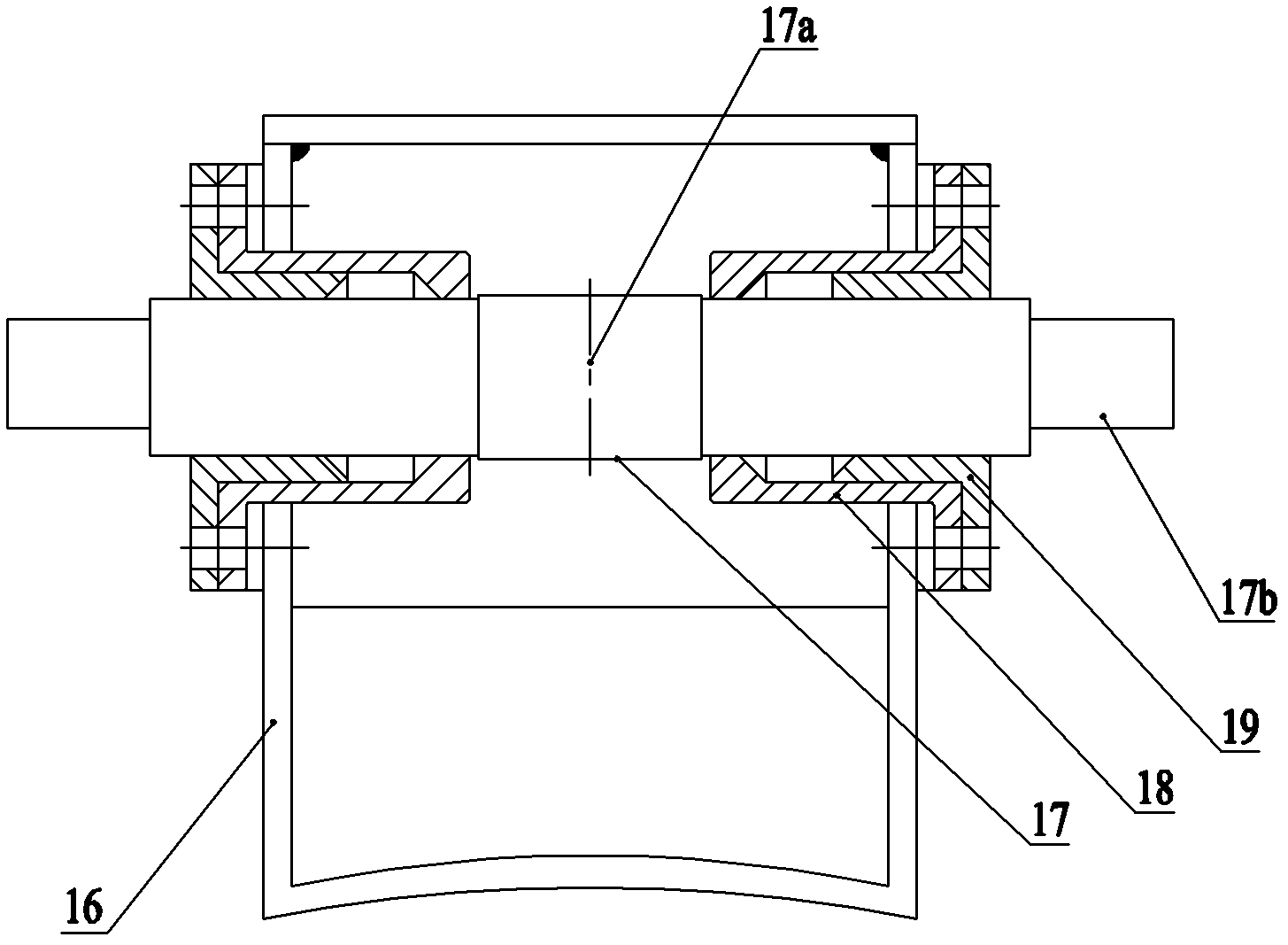

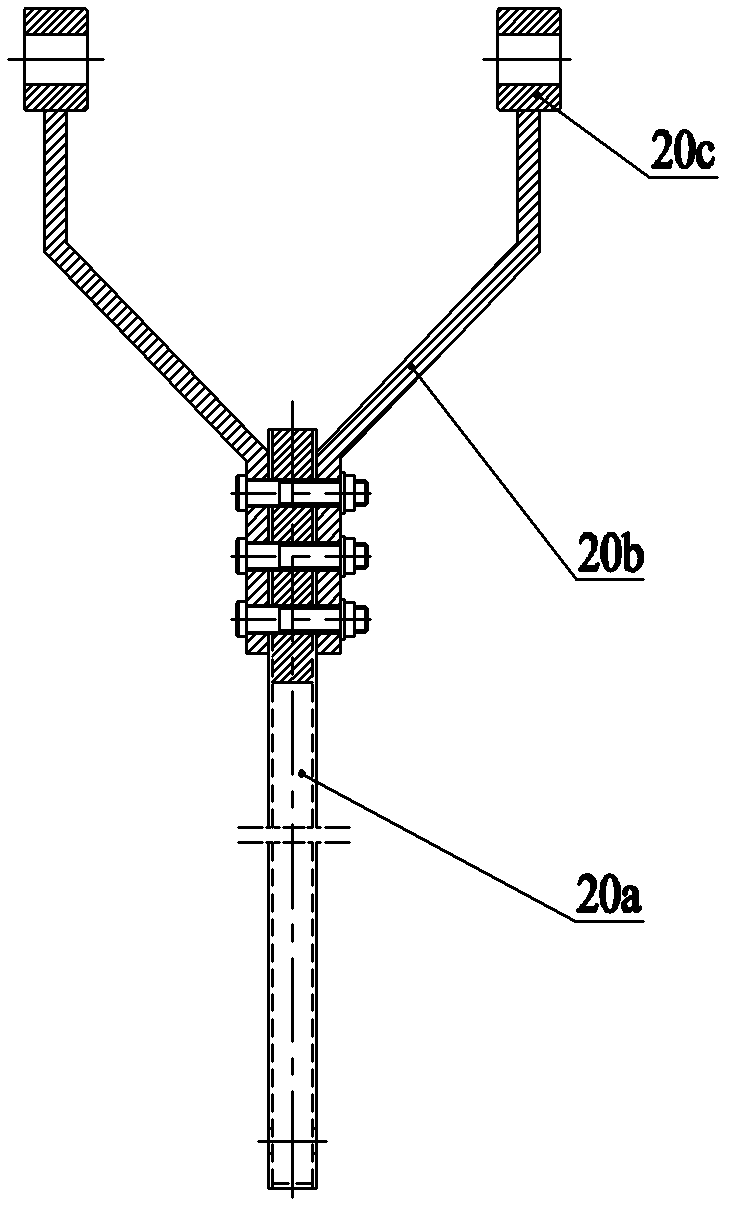

[0025] Such as figure 1 As shown, the charging port of the upper coal hopper 1 is equipped with a cover plate device, and the discharge port of the upper coal hopper 1 is equipped with a sealing seat 5, and the lower end of the sealing seat 5 extends into the feeding port of the lower coal hopper 2, The sealing seat 5 is connected and fixed with the lower coal hopper 2, and a sealing seat 5 is also installed at the outlet of the lower coal hopper 2; a material cup 6 is installed on the upper coal hopper 1 and the lower coal hopper 2 With the material cup lift-and-release mechanism, the material cup 6 is matched with the lower opening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com