Method and special water chilling unit for manufacturing chilled water with large temperature difference in stand-alone three-stage compression manner

A three-stage compression and chilled water technology, applied in compressors, refrigeration components, and irreversible cycle compressors, etc., can solve problems such as lowering refrigeration efficiency, and achieve the effect of reducing energy consumption for transportation, improving energy efficiency, and ensuring refrigeration efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

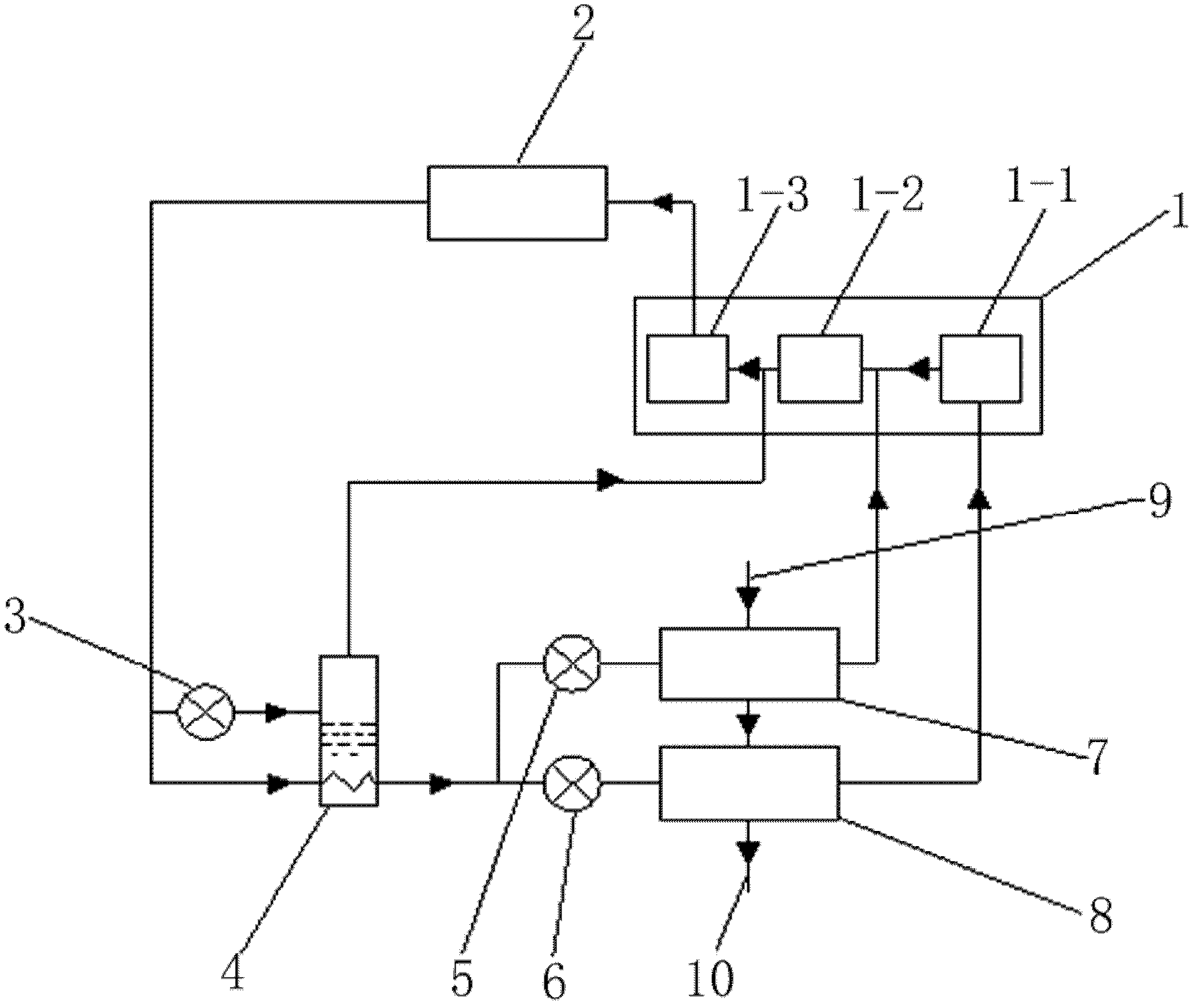

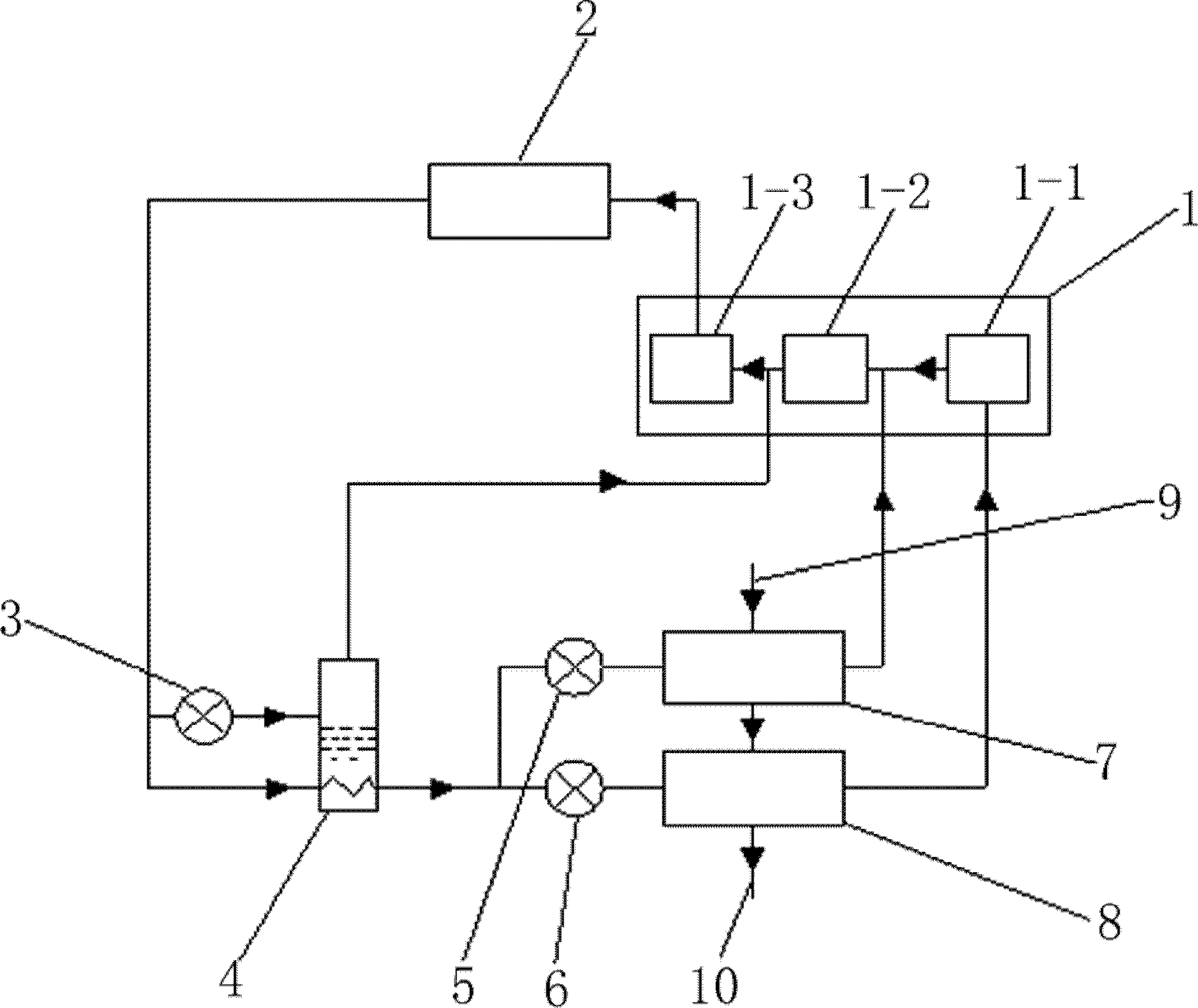

[0022] refer to figure 1 , this embodiment includes a stand-alone three-stage compressor 1, a condenser 2, an intercooler 4, a bypass throttling device 3, a high-temperature loop throttling device 5 and a low-temperature loop throttling device 6, a high-temperature evaporator 7, a low-temperature An evaporator 8, a large temperature difference chilled water return pipe 9 and a large temperature difference chilled water supply pipe 10; the three-stage compressor 1 includes a low pressure stage 1-1, a medium pressure stage 1-2 and a high pressure stage 1-3; The output end of the low-pressure stage section 1-1 is connected to the input end of the medium-pressure stage section 1-2 through a pipeline, and the output end of the medium-pressure stage section 1-2 is connected through the input end of the high-pressure stage section 1-3 of the pipeline; The output end of the high-pressure stages 1-3 of the three-stage compressor 1 is connected to the input end of the condenser 2, and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com