Position detecting device for edge of winding-up H-shaped wheel

An edge position and detection device technology, applied in the direction of measuring devices, electrical devices, instruments, etc., can solve the problems of demanding machining accuracy, lower positioning accuracy, complex structure, etc., and achieve high-precision position detection, convenient control, and detection accuracy high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

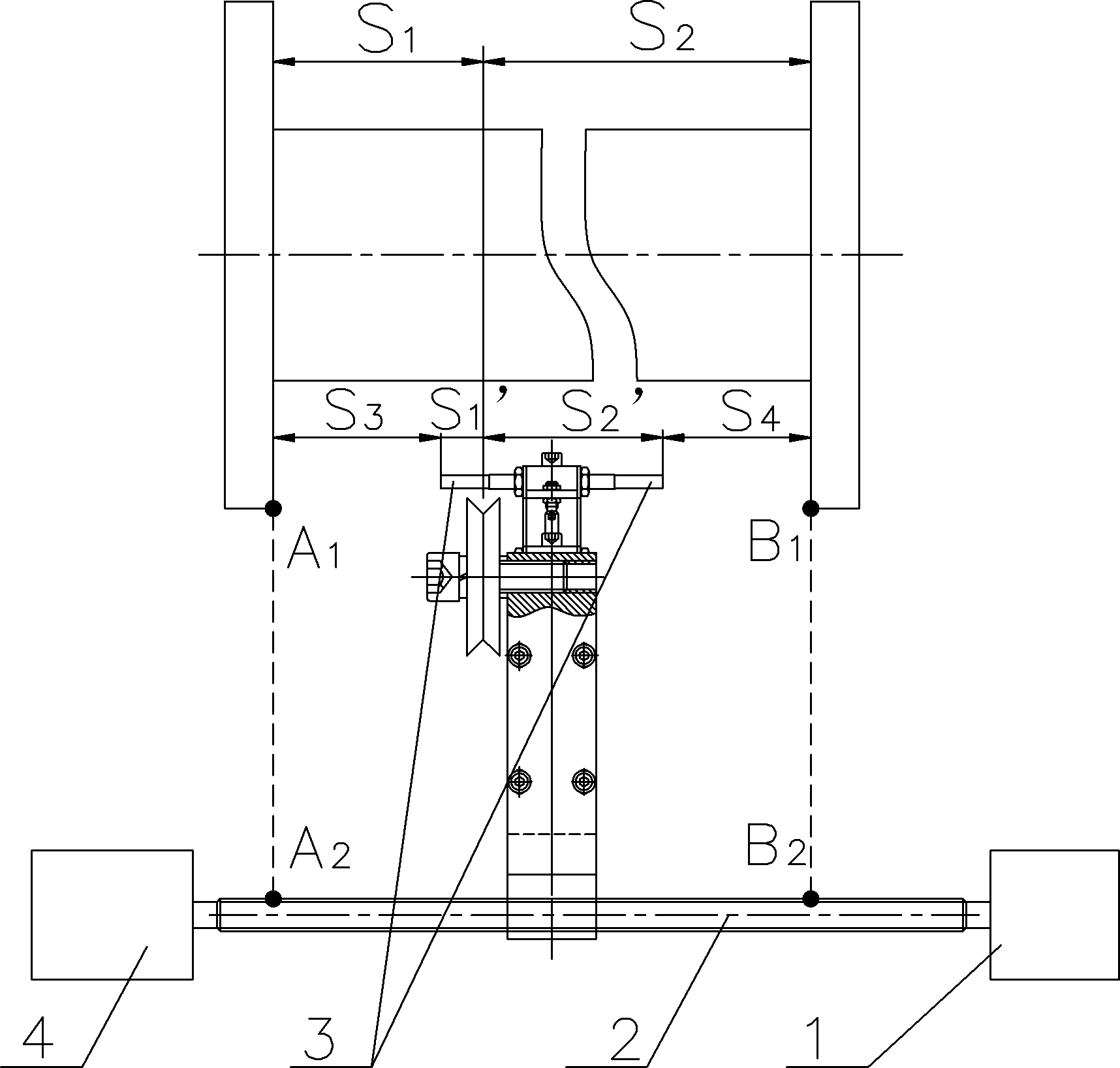

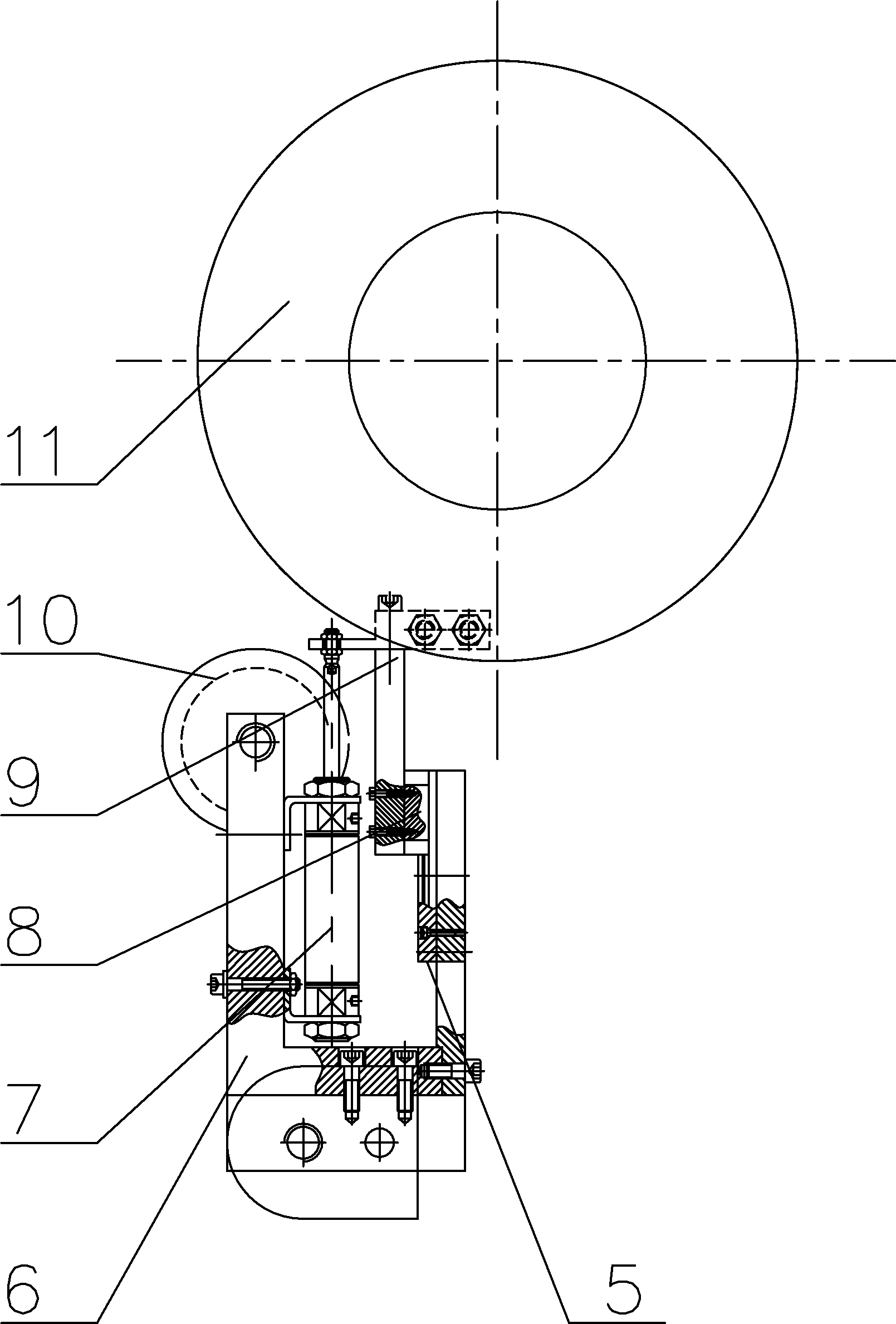

[0022] Such as Figure 1-2 Shown, a kind of take-up I-shaped wheel edge position detection device, it includes: (1) encoder, (2) screw mandrel, (3) displacement sensor, (4) motor, (5) guide rail, (6) Support, (7) cylinder, (8) slide block, (9) position detecting end, (10) lead wheel, (11) I-shaped wheel. The motor is connected with the screw drive, and the support is driven to move laterally through the rotation of the screw. The guide wheel, cylinder, guide rail and slider installed on the guide rail are installed on the support. The position detection end is respectively connected with the front end of the cylinder and the slider. There are two displacement sensors to detect the position of the edge of the I-shaped wheel.

[0023] The edge position detection method of the I-shaped wheel is as follows: the position detection end 9 extends into the I-shaped wheel 11 under the action of the cylinder 7, the screw mandrel 2 rotates, and drives the bracket 6 to move to the left f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com