Precision detection system for rotary transformer

A resolver and precision detection technology, which is applied to instruments, measuring devices, electrical devices, etc., can solve the problems of high construction and maintenance costs of motor test benches, large background noise of motor test benches, and detection effects on accuracy. To achieve the effect of small impact, small size and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] see Figure 4 , The accuracy detection system of the resolver of the present invention includes a turntable 20 , a resolver auxiliary circuit 30 , a data acquisition circuit 40 and a host computer 50 .

[0039] see Figure 5 , the turntable 20 specifically includes a motor controller 21 , a high-speed motor 22 , a tested rotary transformer 13 and a photoelectric rotary encoder 15 . Wherein, the motor controller 21 is used to control the motor 22 to rotate at a constant speed, accelerate or decelerate. The motor 22 is only used to drive the rotary transformer 13 and the photoelectric rotary encoder 15 to rotate, so the power of the motor 22 does not need to be too large. Both the rotary transformer 13 and the photoelectric rotary encoder 15 are assembled on the motor shaft, and the design of this mechanism needs to consider the replacement of the rotary transformer 13 .

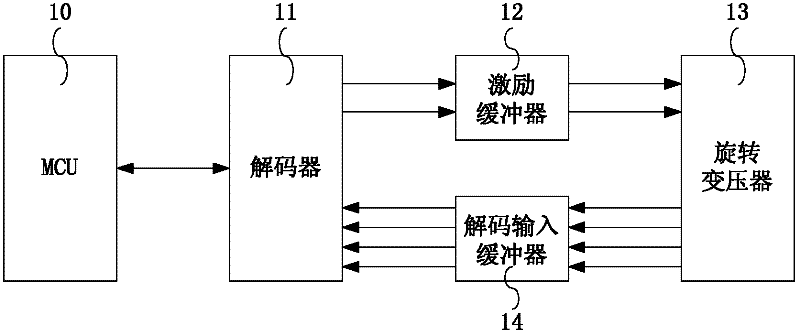

[0040] see Image 6 , the resolver auxiliary circuit 30 specifically includes a decoder 11 , an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com