Device and method for automatically testing and calibrating parameters of battery management systems

A battery management system and automatic calibration technology, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., can solve the problems of low test speed and no guarantee of test integrity, so as to improve research speed and enhance practical value , the effect of improving performance and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Adopt device and method of the present invention to test the performance of a lithium-ion battery management system:

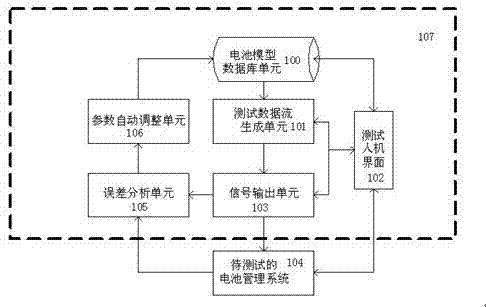

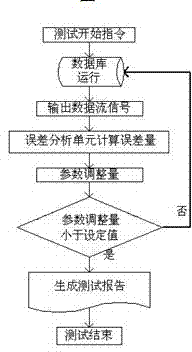

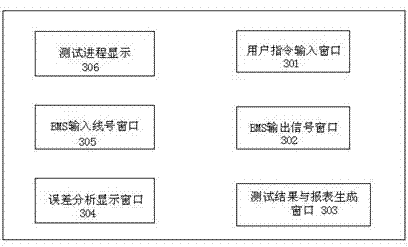

[0036] First set up in this device, set up the battery model database to be tested, connect the battery management system to be tested on the device provided by the present invention, input test order and test parameter (such as test range) in test man-machine interface 102 , the maximum and minimum values of technical parameters such as speed and frequency), and enter the command to start the test. The battery model database unit 100 starts to generate a time series of battery signals in a certain order, such as battery current series, battery voltage series, battery temperature series, etc., and since these series are all generated in the database, they are relevant and consistent sex. After the battery data sequence is output and driven by the signal output unit 103, a signal of a certain voltage or current value is generated and output to the bat...

Embodiment 2

[0038] Adopt the device and method of the present invention to automatically calibrate the voltage ratio parameter of the management system of a lithium-ion battery pack:

[0039] The battery charge or discharge model curve is pre-established in the battery model database unit 100, and the voltage operating range of the battery management system to be tested is input through the test man-machine interface 102, for example, +20V~+1000V; the test step is set, for example every Take a test point at 10V; set the test duration t1 and interval time t2; after startup, the database will automatically generate a voltage value every t2 seconds, and last for t1 seconds, and then increase the voltage value by 10V to generate the second Voltage test signal. The generated voltage value is output to the signal output unit 103, and the circuit converter inside the signal output unit 103 filters the received signal, and then calculates by the microprocessor, and outputs it to the digital-to-an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com