Purple sweet potato noodles and manufacturing method thereof

A manufacturing method and technology of dried noodles, applied in the field of purple potato dried noodles and its manufacturing, can solve problems such as difficulty in extruding into strips, poor viscosity, undiscovered manufacturing method, etc., and achieve the effect of simple process, multi-functionality and rich nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

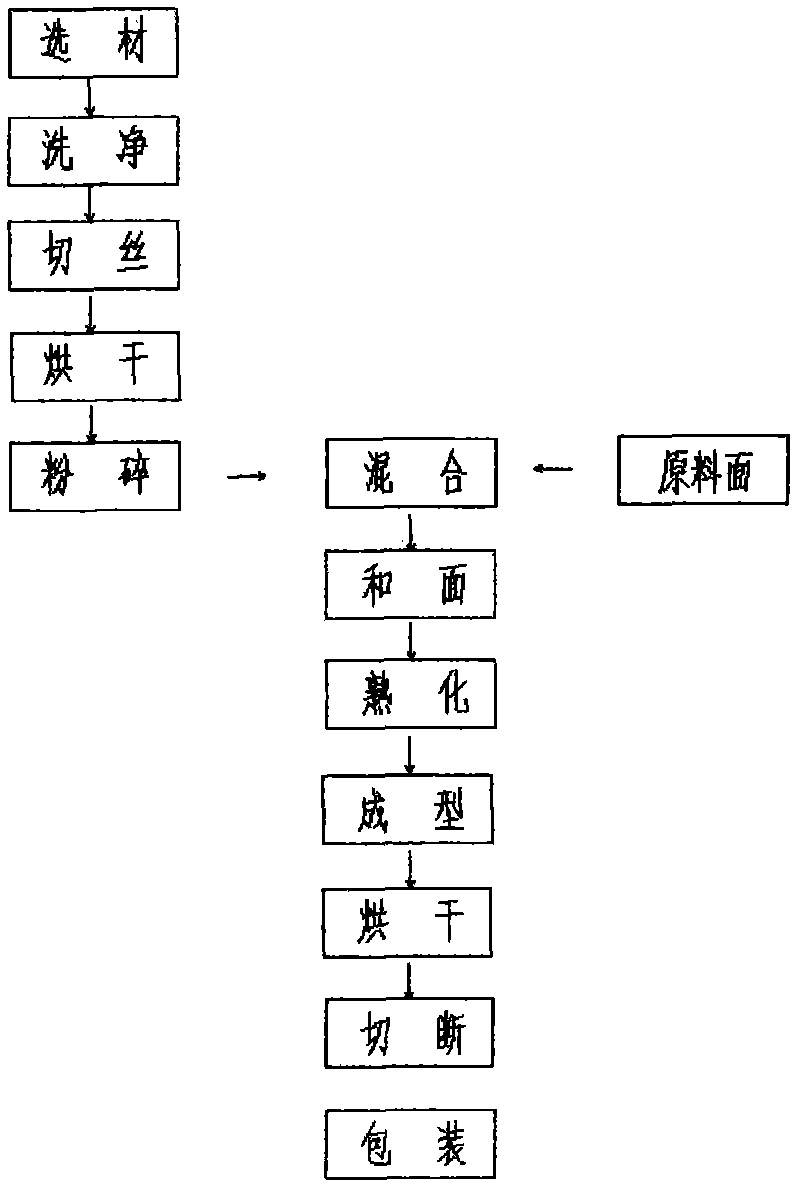

[0073] like figure 1 as shown, figure 1 It is the manufacturing flowchart of Embodiment 1 of the present invention. The manufacturing method is:

[0074] a. Material selection, choose high-quality purple sweet potatoes, wash the purple sweet potatoes and cut them into filaments with a shredder, then dry and dehydrate the filaments at 80-120 degrees Celsius for 1-1.5 hours, and put the dried filaments into ultra-micro Grinder pulverizes, pulverizes and becomes 80-120 order, makes purple sweet potato powder, stand-by;

[0075] b. Configure the raw material noodles: wheat flour is the basis, add any one or more of soybean flour rice flour, wheat flour, oat flour, corn flour, and sorghum rice flour to the wheat flour according to the weight fraction ratio. The raw material noodles are: 60 parts of wheat flour , 5 parts of bean flour, 5 parts of oat flour, 4 parts of rice flour, 2 parts of corn flour, 2 parts of sorghum rice;

[0076] Or, 70 parts of wheat flour, 10 parts of be...

Embodiment 2

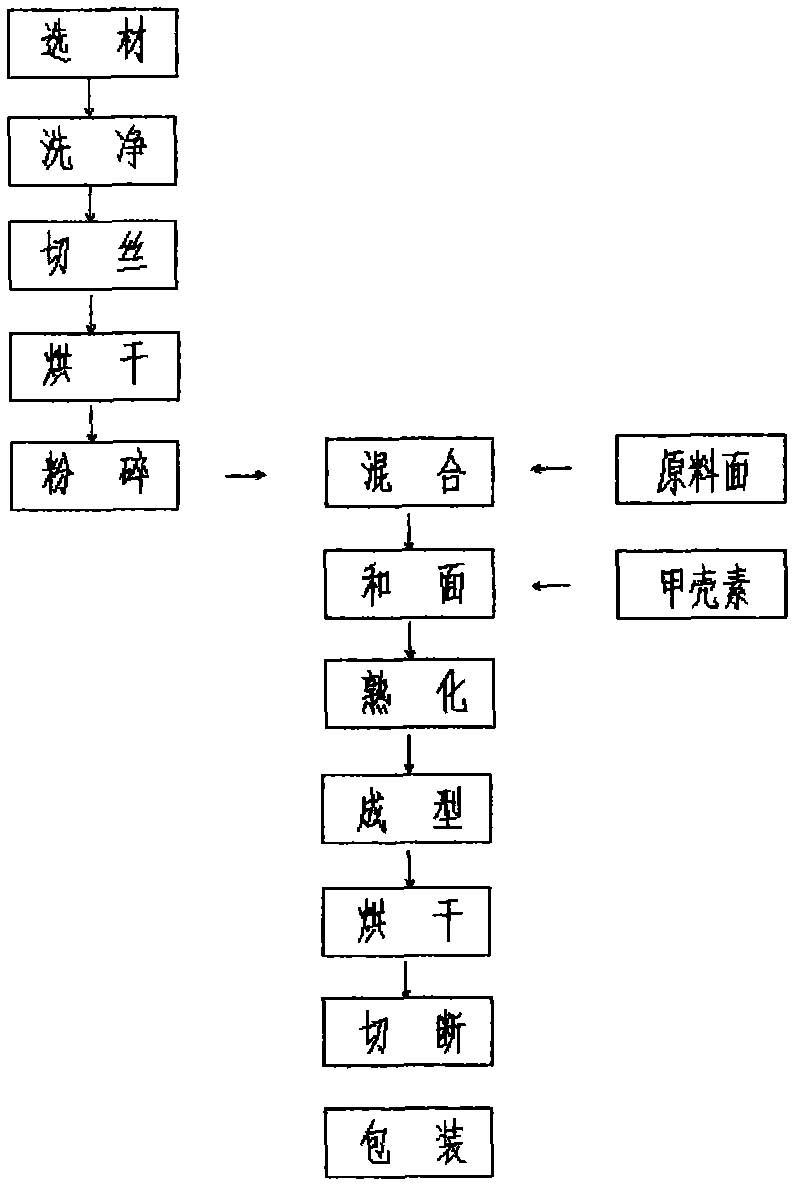

[0091] like figure 2 as shown, figure 2 It is the manufacturing flowchart of Embodiment 2 of the present invention. The manufacturing method is:

[0092] a. Material selection, choose high-quality purple sweet potatoes, wash the purple sweet potatoes and cut them into filaments with a shredder, then dry and dehydrate the filaments at 80-120 degrees Celsius for 1-1.5 hours, and put the dried filaments into ultra-micro Grinder pulverizes, pulverizes and becomes 80-120 order, makes purple sweet potato powder, stand-by;

[0093] b. Configure the raw material noodles: wheat flour is the basis, add any one or more of soybean flour rice flour, wheat flour, oat flour, corn flour, and sorghum rice flour to the wheat flour according to the weight fraction ratio. The raw material noodles are: 60 parts of wheat flour , 5 parts of bean flour, 5 parts of oat flour, 4 parts of rice flour, 2 parts of corn flour, 2 parts of sorghum rice;

[0094] Or, 70 parts of wheat flour, 10 parts of ...

Embodiment 3

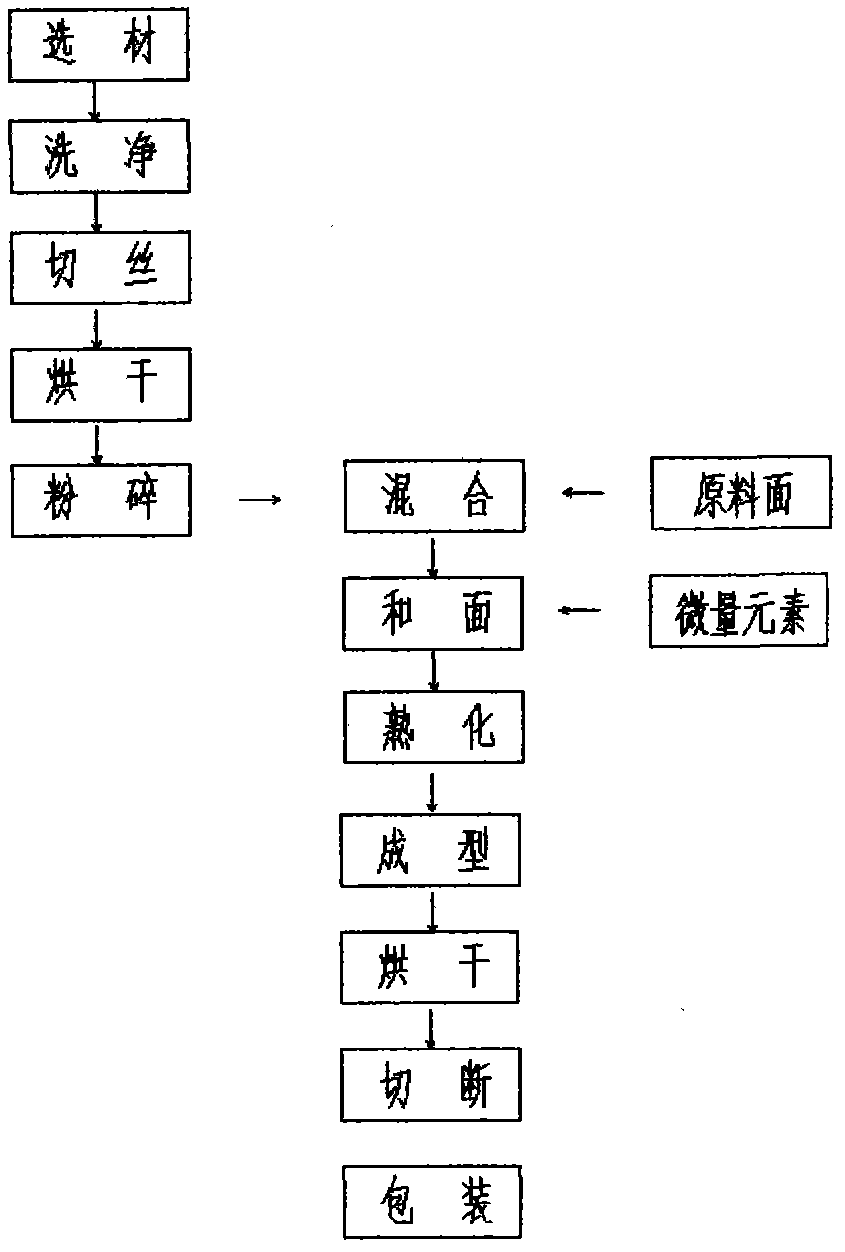

[0110] like image 3 as shown, image 3 It is the manufacturing flowchart of Embodiment 3 of the present invention. The manufacturing method is:

[0111] a. Material selection, choose high-quality purple sweet potatoes, wash the purple sweet potatoes and cut them into filaments with a shredder, then dry and dehydrate the filaments at 80-120 degrees Celsius for 1-1.5 hours, and put the dried filaments into ultra-micro Grinder pulverizes, pulverizes and becomes 80-120 order, makes purple sweet potato powder, stand-by;

[0112] b. Configure the raw material noodles: wheat flour is the basis, add any one or more of soybean flour rice flour, wheat flour, oat flour, corn flour, and sorghum rice flour to the wheat flour according to the weight fraction ratio. The raw material noodles are: 60 parts of wheat flour , 5 parts of bean flour, 5 parts of oat flour, 4 parts of rice flour, 2 parts of corn flour, 2 parts of sorghum rice;

[0113] Or, 70 parts of wheat flour, 10 parts of be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com