Flue gas desulfurizing tower

A desulfurization tower and flue gas technology, applied in the direction of dispersed particle separation, chemical instruments and methods, separation methods, etc., can solve problems such as poor flow field stability, increased boiler oxygen content, and asymmetric process distribution, so as to simplify the structure and improve The effect of smooth distribution, simplified intake ducting and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

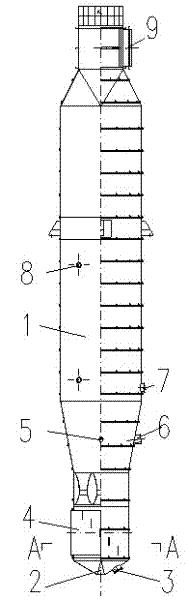

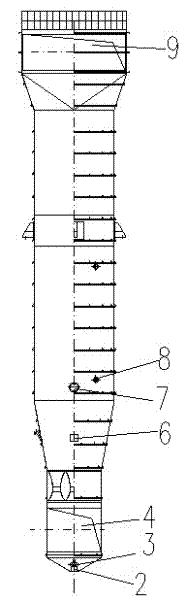

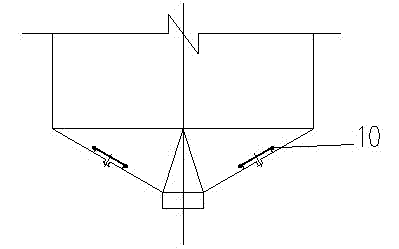

[0024] Below in conjunction with accompanying drawing, the present invention is described in detail, as figure 1 as shown, figure 2 As shown, a flue gas desulfurization tower of the present invention includes a tower body 1 composed of a flue chamber, a spray chamber and a desulfurization chamber, and a desulfurization slag outlet 2, an ash opening 3 and a flue gas outlet are arranged at the lower part of the tower body 1. Inlet 4, return ash inlet 6, desulfurizer inlet 5 and nozzle interface 8 are arranged in the middle of tower body 1, flue gas outlet 9 is arranged at the upper end of tower body 1, between desulfurization slag outlet 2 and flue gas inlet 4 The gap is the desulfurization tower outlet necking section, the necking section is in the shape of a sky circle, and an annular air distribution device 10 is arranged on the inner circular cone slope of the necking section, see image 3 and Figure 4 , the air distribution device 10 has an air outlet with the wind dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com