Four-axis linkage automatic spot welding machine

A four-axis linkage and spot welding machine technology, which is applied to welding equipment, resistance welding equipment, resistance electrode holders, etc., can solve the problems of high equipment cost investment, high labor intensity, and large occupied area, so as to reduce equipment cost investment, Reduce labor intensity, perfect effect of workpiece solder joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

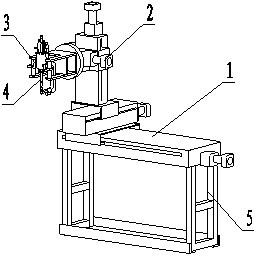

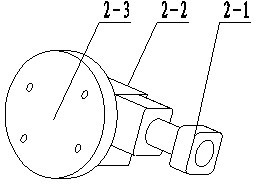

[0023] Referring to Fig. 1, the present invention comprises a parallel movement mechanism 1, a rotation mechanism 2, a welding tongs suspension mechanism 3, a welding tongs 4 and a base 5, the base 5 is a frame structure, and the parallel movement mechanism 1 is installed on the base 5 , the rotating mechanism 2 is connected to the parallel moving mechanism 1 through connecting brackets 1-4, the welding tongs suspension mechanism 3 is fixedly connected to the rotation mechanism 2, and the welding tongs 4 is installed on the welding tongs suspension mechanism 3.

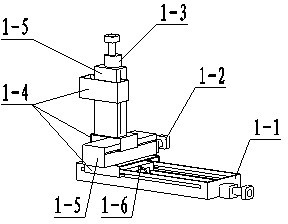

[0024] see figure 1 , figure 2 , the parallel movement mechanism 1 in the formation of the present invention is made up of horizontal lateral movement unit 1-1, horizontal longitudinal movement unit 1-2 and vertical movement unit 1-3, dust cover 1-5 is all installed outside each parallel movement unit , the adjacent parallel moving units are connected through the corresponding connecting brackets 1-4.

[0025] see ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com