Monocular vision material loading and unloading robot system of numerical control lathe and method thereof

A robot system, CNC lathe technology, applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve the problems of complex control system and high cost of realization, and achieve the effect of simple principle, simple structure and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

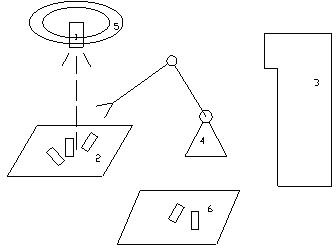

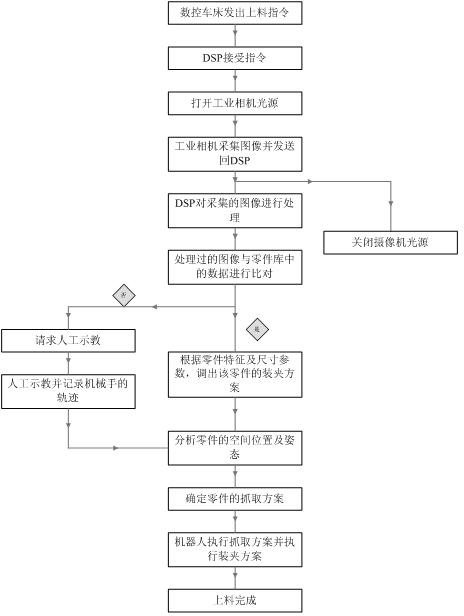

[0020] The light source in the present invention refers to a special light source for machine vision, which is used to provide illumination when the camera 1 collects images. The camera 1 is connected to the image acquisition card through the 1394 data line, and the image acquisition card is installed on the DSP. The industrial CCD camera 1 is installed above the loading platform, and the camera 1 is surrounded by a ring light source 5 . The selected DSP model is TMS320DM642, this type of DSP has powerful image processing capability and computing capability. The teaching box adopts MCS-51 series single-chip microcomputer to complete the receiving and sending of control signals. The DSP transmits the detected current position data of each axis to the single-chip microcomputer, and receives the control signals and teaching signals of each axis movement from the single-chip microcomputer. As the center of the control system, DSP integrates the six-axis motion control card throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com