PTC (Positive Temperature Coefficient) exothermic material and preparation method thereof as well as PTC exothermic sheet

A heating material and heating sheet technology, applied in heating element materials, electric heating devices, ohmic resistance heating, etc., can solve the problems of partial thickness flexibility, insufficient and other problems, achieve good flexibility, thin thickness, improve the safety and stability of use sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Example 1: A PTC heating material, its components include N, N-dimethylformamide, polyvinylidene fluoride and carbon powder, the N, N-dimethylformamide is a solvent, every 100ml N, N-di 8.0g-11.2g of polyvinylidene fluoride and 1.1-3.2g of carbon powder are miscible in the methyl formamide solution.

[0017] In order to increase the viscosity of the N, N-dimethylformamide solution, the component also includes a surface modifier montmorillonite, and 0.1 g of montmorillonite is added to every 100 ml of N, N-dimethylformamide solution.

[0018] Wherein, the carbon powder particles include carbon powder and carbon particles, and 0.5-2.0 g of carbon powder and 0.6-1.2 g of carbon particles are respectively added to every 100 ml of N,N-dimethylformamide solution.

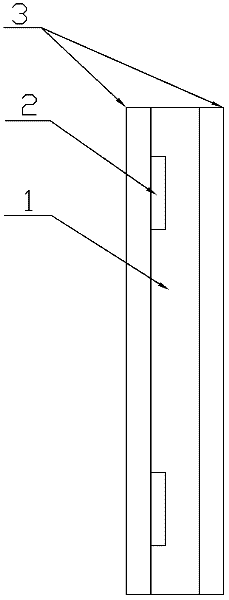

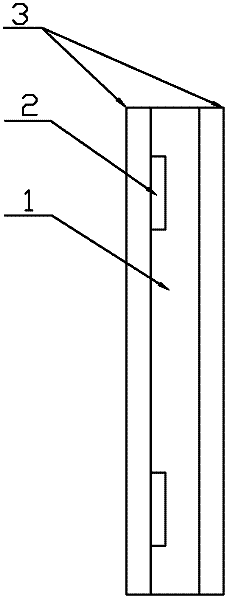

[0019] A PTC heating sheet, such as figure 1 As shown, it includes a base material 1 and a wire 2 pressed on the base material 1 .

[0020] In order to improve the safety of use, the PTC heating sheet also incl...

Embodiment 2

[0048] Example 2: A PTC heating material, its components include N, N-dimethylformamide, polyvinylidene fluoride and carbon powder, the N, N-dimethylformamide is a solvent, every 100ml N, N-di Mix 8.0g-11.2g of polyvinylidene fluoride and 15-25g of aluminum powder in the methylformamide solution.

[0049] Specifically:

[0050] N,N-Dimethylformamide 70ml

[0051] Polyvinylidene fluoride 12.8g

[0052] Aluminum powder 20g

[0053] Montmorillonite 0.1g

[0054] Take 70ml of N,N-dimethylformamide, add 8.0g of polyvinylidene fluoride powder and mix, stir for 30min to make it evenly mixed, add 20g of aluminum powder and stir for 30min, put it in an oven, and heat at 80°C for 5min A blank is formed, molded with a mold, and then baked at 120° C. for 30 minutes to form a base material.

[0055] The structure of the PTC heating sheet is the same as in Example 1. For a specific example of a PTC heating sheet, take a 7*25cm base material, use thre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com