Passivation method of excimer laser gas configuration device

An excimer laser and configuration device technology, applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve problems such as inability to meet demand, low F2 content, etc., to prevent further corrosion, form stable, cost-effective low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

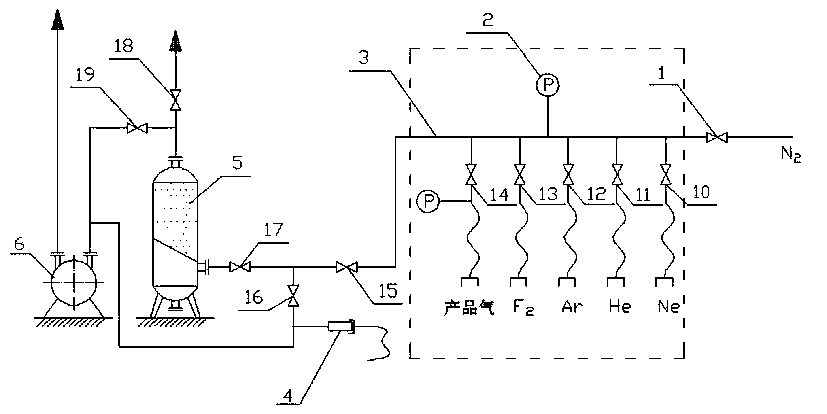

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0016] Please refer to figure 1 , the passivation method of a kind of excimer laser gas configuration device of the present invention, this method comprises the following steps:

[0017] The first step: pre-passivation treatment: clean up the impurities in the configuration device, and use N 2 Blow off the excimer laser gas configuration device; specifically, to clean up impurities such as dirt in the pipeline in the configuration device, and then use high-purity N 2 Blow off, then seal for later use.

[0018] Step 2: Passivation treatment: Inject F into the excimer laser gas configuration device 2 Mixed gas with He, after constant temperature and pressure for a period of time, use N 2 Blow off the excimer laser gas configuration device; it is divided into three steps:

[0019] A) Keep the temperature of the excimer laser gas configuration device at 40-6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com